A high-temperature box resistance furnace is the foundational instrument for conducting isothermal oxidation tests, providing the strictly controlled environment necessary to isolate the chemical breakdown of thermal barrier coatings. By generating a uniform heat field for extended durations, this equipment enables researchers to bypass complex mechanical variables and focus exclusively on the material's reaction to prolonged thermal exposure.

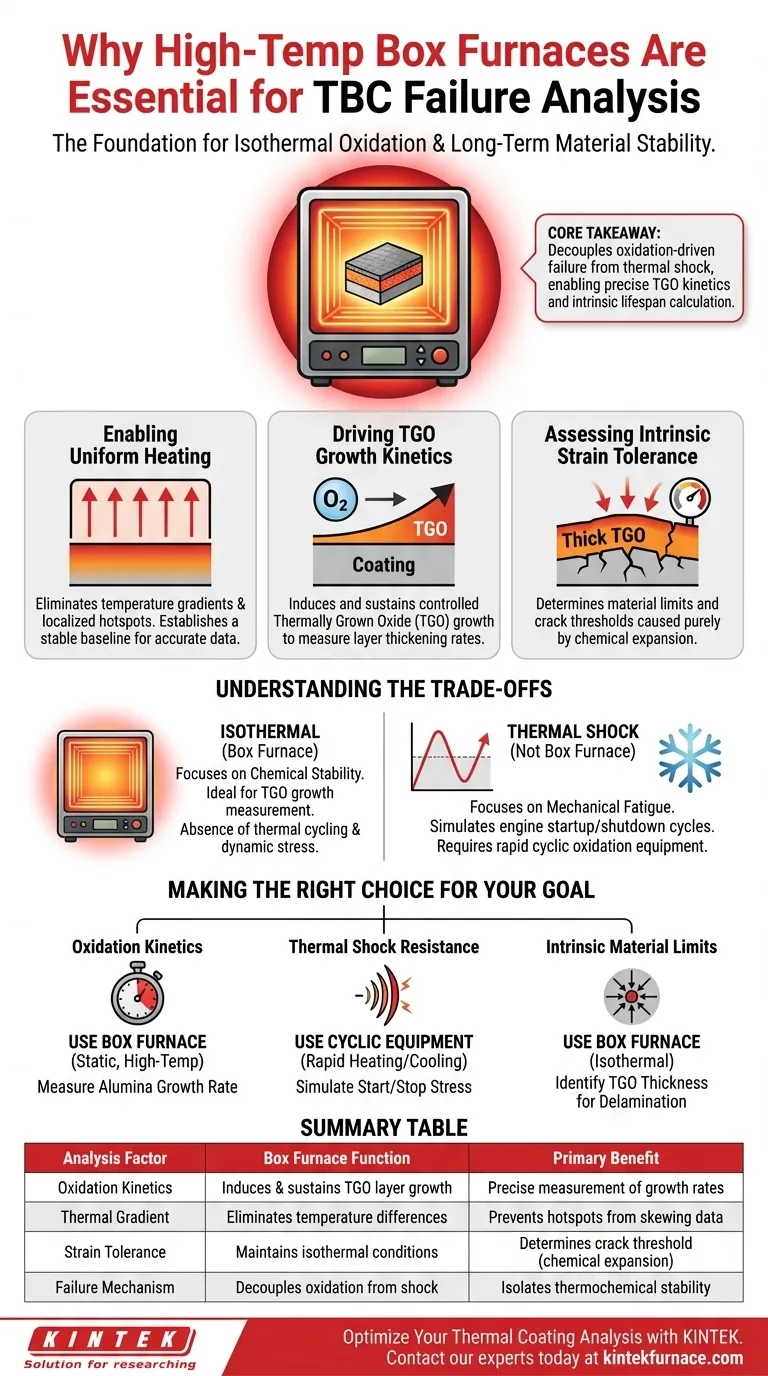

Core Takeaway The box furnace serves a singular, critical purpose: it decouples oxidation-driven failure from thermal shock. By eliminating temperature gradients, it allows for the precise calculation of Thermally Grown Oxide (TGO) kinetics, revealing the coating's intrinsic chemical lifespan and strain tolerance.

The Mechanics of Long-Term Failure Analysis

To understand why a coating fails over thousands of service hours, researchers must simulate the cumulative effects of heat without the interference of rapid temperature changes.

Enabling Uniform Heating

In real-world applications, coatings experience drastic temperature differences across their surface. However, to analyze failure, you must first establish a baseline.

The box furnace provides a stable, gradient-free environment. This ensures that every part of the specimen experiences the exact same thermal load, preventing localized hotspots from skewing the data.

Driving TGO Growth Kinetics

The primary mechanism of long-term failure in thermal barrier coatings is the formation of Thermally Grown Oxides (TGO).

As oxygen penetrates the topcoat, it reacts with the bond coat to form a layer (often alumina). The box furnace is essential for inducing and sustaining this growth under controlled conditions, allowing scientists to measure exactly how fast this layer thickens (kinetics) over hundreds of hours.

Assessing Intrinsic Strain Tolerance

As the TGO layer grows, it exerts stress on the surrounding material.

By using a box furnace to maintain a constant temperature, researchers can determine the intrinsic strain tolerance of the coating. This reveals how much oxide growth the material can handle before it cracks or delaminates, purely due to internal chemical expansion rather than external mechanical shock.

Understanding the Trade-offs

While the box resistance furnace is vital for studying oxidation, it is an idealized test environment. It is crucial to understand what it does not simulate to interpret the data correctly.

The Absence of Thermal Cycling

This equipment excels at isothermal (constant temperature) testing.

It does not typically simulate the rapid heating and cooling cycles (thermal shock) that an engine component endures during startup and shutdown. Therefore, data from a box furnace represents the material's chemical stability, not its resistance to thermal fatigue.

Static vs. Dynamic Stress

The environment inside the box furnace is static.

It allows for the observation of phase structure evolution and oxide formation, but it generally does not apply the mechanical loads (such as centrifugal force or vibration) present in actual service. It isolates the thermochemical stability but ignores aerodynamic forces.

Making the Right Choice for Your Goal

When designing a testing protocol for thermal barrier coatings, the box furnace is a specific tool for a specific phase of analysis.

- If your primary focus is oxidation kinetics: Use the box furnace to maintain a static, high-temperature (e.g., $1300^\circ\text{C}$) environment to measure the growth rate of the protective alumina layer.

- If your primary focus is thermal shock resistance: You must look beyond the standard box furnace to equipment capable of rapid cyclic oxidation (heating and active cooling) to simulate start/stop stress.

- If your primary focus is intrinsic material limits: Use the box furnace to identify the exact TGO thickness that triggers delamination in the absence of external thermal gradients.

The high-temperature box furnace provides the quiet, stable backdrop required to hear the "ticking clock" of chemical oxidation before the noise of mechanical failure takes over.

Summary Table:

| Analysis Factor | Box Furnace Function | Primary Benefit |

|---|---|---|

| Oxidation Kinetics | Induces & sustains TGO layer growth | Precise measurement of alumina growth rates |

| Thermal Gradient | Eliminates temperature differences | Prevents localized hotspots from skewing data |

| Strain Tolerance | Maintains isothermal conditions | Determines crack threshold from chemical expansion |

| Failure Mechanism | Decouples oxidation from shock | Isolates thermochemical stability from mechanical fatigue |

Optimize Your Thermal Coating Analysis with KINTEK

Precise failure analysis requires the uncompromising thermal stability that only expert-engineered equipment can provide. Backed by industry-leading R&D and manufacturing, KINTEK offers a comprehensive range of high-temperature laboratory solutions including Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research demands.

Whether you are measuring TGO kinetics or testing material limits, our furnaces deliver the uniform heat fields necessary for reliable data.

Ready to elevate your material testing? Contact our experts today to find the perfect furnace for your laboratory.

Visual Guide

References

- Robert Vaßen. Insight into the Process-Microstructure-Property Relationship: Single Splat Analysis, Adhesion Testing, and Thermal Cycling of Inner Diameter (ID) Thermal Barrier Coatings. DOI: 10.21203/rs.3.rs-8250483/v1

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- What are the general characteristics and advantages of box type resistance furnaces? Discover Versatile Heating Solutions for Your Lab

- How are muffle furnaces applied in heat treatment processes? Achieve Precise Control for Superior Material Properties

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What are common uses of muffle furnaces? Unlock Precision in Analysis and Material Processing

- How are muffle furnaces used in ceramic material processing? Unlock Precision Sintering for High-Performance Ceramics

- What is the primary function of a muffle furnace in CNM-Cl synthesis? Master Precision Thermal Polycondensation

- Why is a high-precision high-temperature furnace required for chemical activation? Ensure Superior Carbon Quality