At its core, a muffle furnace is a specialized high-temperature oven designed for a wide range of laboratory and industrial processes. Its most common uses involve quantitative analysis through ashing, altering the properties of materials via heat treatment, and manufacturing components in fields like ceramics, metallurgy, and material science.

The fundamental value of a muffle furnace is its ability to provide extremely high, uniform heat while isolating the material inside a chamber (the "muffle"). This prevents contamination from the heating elements, ensuring the purity and integrity of the process.

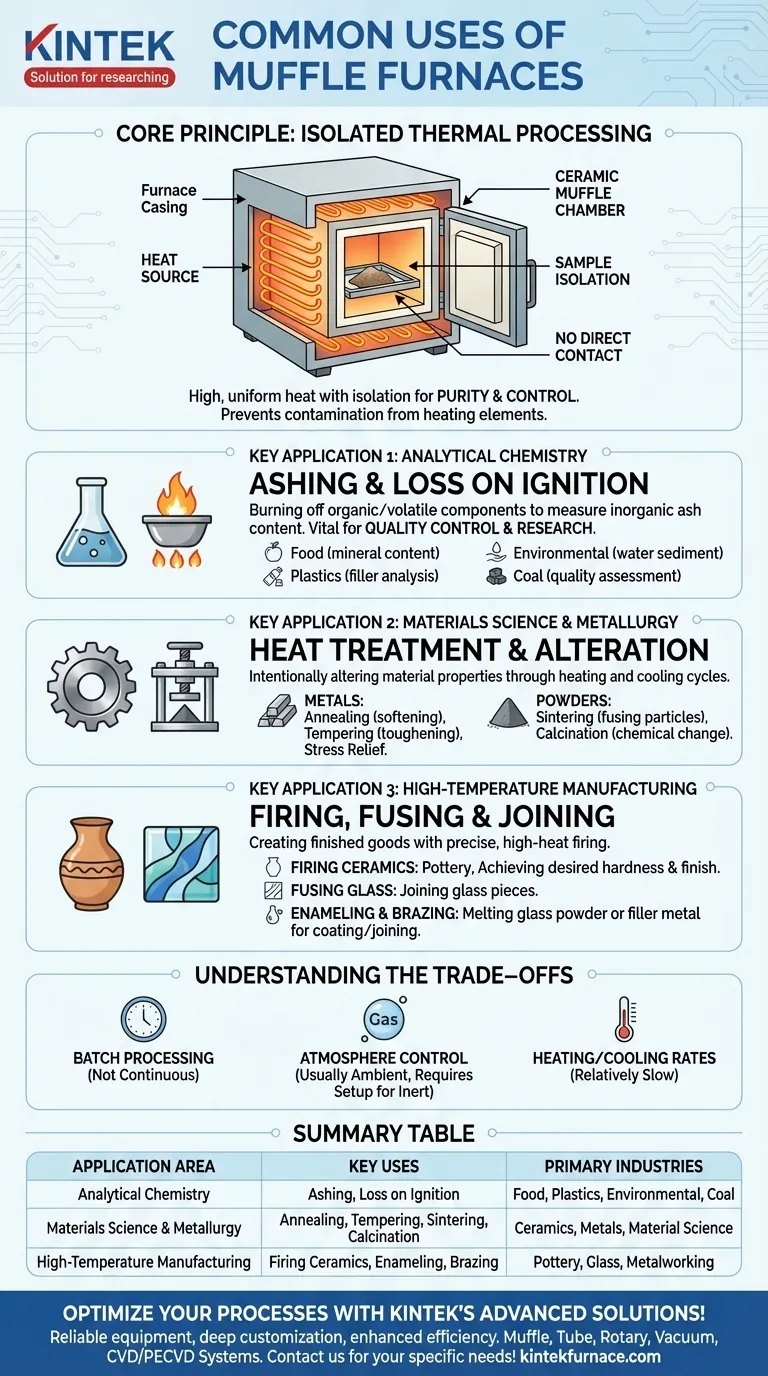

The Core Principle: Isolated Thermal Processing

What is a "Muffle"?

A muffle furnace contains a processing chamber made of a high-temperature, non-reactive material, often a type of ceramic.

This chamber, the "muffle," is heated from the outside by electric resistance elements. The material being processed is placed inside the muffle, never coming into direct contact with the heating source itself.

Why Isolation is Critical

This design is crucial for two reasons: purity and control.

By isolating the sample, the furnace prevents contamination from fuel byproducts or degrading heating elements. This is essential for accurate chemical analysis. It also allows for a more controlled and uniform thermal environment.

Key Application 1: Analytical Chemistry

This is one of the most common uses for a muffle furnace, especially in laboratory settings. The goal is to measure a material's composition by burning off specific components.

Ashing and Loss on Ignition

Ashing is a process where a sample is heated to a high temperature to burn away all organic and volatile substances.

What remains is the inorganic, non-combustible "ash". By weighing the sample before and after ashing, analysts can precisely determine the percentage of ash content. This is also known as a Loss on Ignition (LOI) test.

Where This Is Used

This technique is vital for quality control and research in numerous industries, including determining the mineral content of food, analyzing fillers in plastics, measuring sediment in water samples, or assessing the quality of coal.

Key Application 2: Materials Science and Metallurgy

In this field, the furnace is not used to measure what's lost, but to intentionally change the physical properties of the material itself through heat.

Heat Treatment of Metals

Different heating and cooling cycles can drastically alter a metal's characteristics. Common processes include:

- Annealing: Heating and slowly cooling a metal to soften it, relieve internal stresses, and improve its workability.

- Tempering: Heating a previously hardened metal to a lower temperature to decrease its brittleness and increase its toughness.

- Stress Relief: A low-temperature heat treatment used to reduce internal stresses caused by machining, welding, or cold working.

Sintering and Calcination

Sintering is the process of heating powdered materials to a temperature just below their melting point. This causes the particles to fuse, creating a solid, dense object. It's a key step in creating ceramics and certain metal parts.

Calcination involves heating a material to drive off a specific component, inducing a chemical change. A classic example is heating limestone to produce lime and release carbon dioxide.

Key Application 3: High-Temperature Manufacturing

Beyond analysis and property alteration, muffle furnaces are used to create finished goods that require precise, high-temperature firing.

Firing Ceramics and Fusing Glass

The controlled, uniform heat of a muffle furnace is perfect for firing pottery and ceramics. It allows for precise temperature ramps and holds, which are critical for achieving the desired hardness, color, and finish. It's also used for fusing pieces of glass together.

Enameling and Brazing

Creating enamel coatings on metal requires melting glass powder onto a surface, a process that demands the clean, high-heat environment of a muffle furnace.

Similarly, brazing and soldering use the furnace to melt a filler metal, which then flows between two close-fitting parts to join them together.

Understanding the Trade-offs

While incredibly useful, muffle furnaces have specific limitations you must consider for your application.

Batch Processing vs. Continuous Flow

Muffle furnaces are inherently batch processors. You load the chamber, run the cycle, and unload it. They are not designed for large-scale, continuous manufacturing lines, where a tunnel kiln might be more appropriate.

Atmosphere Control

A standard muffle furnace operates in an ambient air atmosphere. While this is suitable for most applications like ashing, some metallurgical processes require an inert (e.g., argon) or reactive atmosphere. This requires a specialized, sealed furnace with gas inlets.

Heating and Cooling Rates

The thermal mass of the ceramic muffle means that heating and cooling can be relatively slow. For processes requiring extremely rapid temperature changes (quenching), the furnace is only used for the heating step before the material is removed and cooled separately.

Making the Right Choice for Your Goal

To apply this knowledge, identify your primary objective.

- If your primary focus is determining composition: You will use the furnace for ashing or Loss on Ignition to precisely measure inorganic or non-volatile content.

- If your primary focus is altering a material's physical state: You will employ heat treatment processes like annealing to soften metal or sintering to create a dense part from powder.

- If your primary focus is creating a finished part: Your task will be firing ceramics, creating an enamel coating, or joining components through brazing.

By understanding these core functions, you can leverage the muffle furnace as a powerful and precise tool for analysis, material transformation, and manufacturing.

Summary Table:

| Application Area | Key Uses | Primary Industries |

|---|---|---|

| Analytical Chemistry | Ashing, Loss on Ignition | Food, Plastics, Environmental, Coal |

| Materials Science & Metallurgy | Annealing, Tempering, Sintering, Calcination | Ceramics, Metals, Material Science |

| High-Temperature Manufacturing | Firing Ceramics, Enameling, Brazing | Pottery, Glass, Metalworking |

Optimize your laboratory processes with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing purity, control, and efficiency. Contact us today to discuss how we can support your specific applications in ashing, heat treatment, or manufacturing!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?