In short, muffle furnaces are used in heat treatment for processes like annealing, hardening, tempering, and normalizing. They excel at these tasks because their enclosed chamber, or "muffle," isolates the material from the heating elements, allowing for extremely precise temperature control and a controlled atmosphere. This prevents contamination and ensures the material's properties are altered uniformly and predictably.

The true value of a muffle furnace in heat treatment isn't just its ability to get hot, but its ability to create a perfectly controlled and isolated environment. This allows metallurgists to precisely manipulate a material's internal structure without damaging its surface.

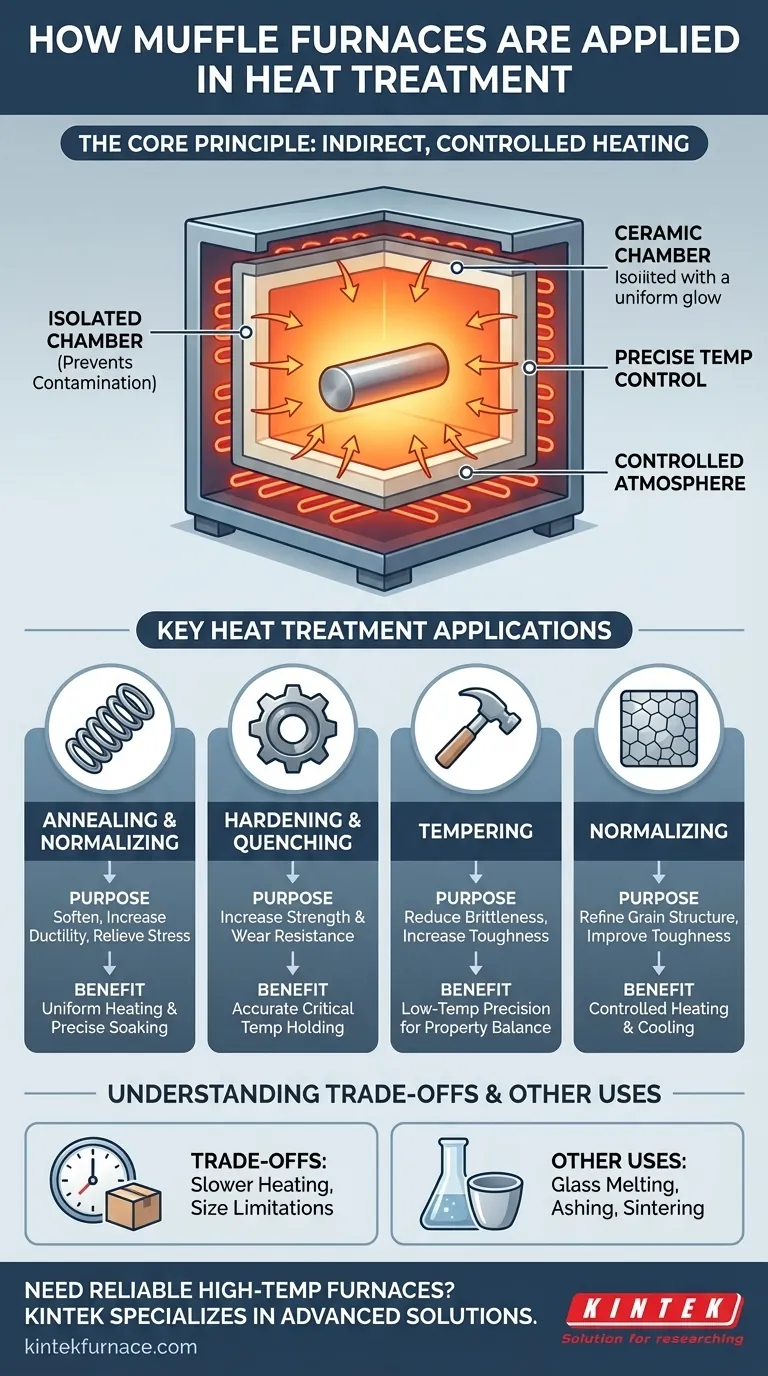

The Core Principle: Indirect, Controlled Heating

A muffle furnace is defined by its core design feature: the muffle. Understanding this component is key to understanding its application in heat treatment.

What is a "Muffle"?

A muffle is a dedicated chamber made of a high-temperature, thermally conductive material, often a ceramic. The material to be heat-treated is placed inside this chamber.

The heating elements of the furnace heat the outside of the muffle. Heat then transfers through the muffle walls to uniformly heat the material inside.

The Benefit of Isolation

This indirect heating method is the furnace's primary advantage. The material never comes into direct contact with the heating elements or any byproducts of combustion.

This isolation prevents surface reactions like oxidation and decarburization, which can compromise the integrity of the finished part. It also enables the introduction of a specific gas (like nitrogen or argon) to create a controlled, non-reactive atmosphere.

Achieving Uniformity and Precision

By heating the entire muffle chamber, the furnace provides exceptionally uniform radiant heat from all directions. This eliminates hot spots and ensures the entire workpiece reaches the target temperature evenly, which is critical for consistent results in heat treatment.

Key Heat Treatment Applications

The precise control offered by a muffle furnace makes it ideal for the most common metallurgical processes. Each process uses a specific thermal cycle to achieve a different mechanical property.

Annealing and Normalizing

These processes are used to soften metals, increase their ductility, and relieve internal stresses. Both involve heating the material to a specific temperature and then cooling it at a controlled, often slow, rate. The muffle furnace ensures the heating and soaking temperatures are held with high precision.

Hardening and Quenching

Hardening is used to increase the strength and wear resistance of a material, particularly steel. It requires heating the metal to a critical temperature before it is rapidly cooled (quenched) in a medium like oil, water, or air. The muffle furnace's ability to hit and hold that precise temperature is essential for a successful hardening cycle.

Tempering

After a part is hardened, it is often extremely brittle. Tempering is a subsequent, lower-temperature heat treatment that reduces this brittleness and increases toughness. The precise temperature control of a muffle furnace is critical, as even small deviations can drastically alter the final balance of hardness and toughness.

Understanding the Trade-offs

While highly effective, muffle furnaces are not the universal solution for all heating tasks. Their design brings specific limitations.

Slower Heating Rates

Because the heat must transfer indirectly through the muffle walls, the time it takes to reach the target temperature can be longer than in a direct-fired furnace. This makes them less efficient for very high-volume production where cycle time is the primary concern.

Size and Volume Limitations

Muffle furnaces are typically designed for laboratory-scale work or the treatment of smaller components. The complexity and cost of manufacturing very large ceramic muffles limit their use for treating massive parts, which are often handled in larger, direct-fired or induction furnaces.

Applications Beyond Metals

The principles of precise, clean heating make muffle furnaces valuable in other industries. They are used for melting and shaping glass, ashing samples for chemical analysis, and sintering ceramic and metal injection molded parts.

Making the Right Choice for Your Goal

Your choice of heat treatment process depends entirely on the desired final properties of the material.

- If your primary focus is to soften a material for easier machining: Use annealing to increase ductility and relieve internal stresses.

- If your primary focus is to achieve maximum hardness and wear resistance: Use a hardening process, followed by tempering to reduce brittleness.

- If your primary focus is to refine the grain structure and improve toughness: Use normalizing for a more uniform and desirable microstructure.

Ultimately, the muffle furnace is a tool of precision, enabling you to transform a material's fundamental properties in a highly controlled and repeatable way.

Summary Table:

| Process | Purpose | Key Benefit of Muffle Furnace |

|---|---|---|

| Annealing | Soften metal, increase ductility | Precise temperature control for uniform heating |

| Hardening | Increase strength and wear resistance | Accurate critical temperature holding |

| Tempering | Reduce brittleness, increase toughness | Low-temperature precision for property balance |

| Normalizing | Refine grain structure, improve toughness | Controlled heating and cooling for consistency |

Need a reliable high-temperature furnace for your lab? KINTEK specializes in advanced solutions like Muffle, Tube, and Vacuum Furnaces, backed by deep customization to meet your unique experimental needs. Enhance your heat treatment processes with our precision engineering—contact us today to discuss how we can support your research and development!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis