At its core, a box type resistance furnace is a foundational piece of thermal processing equipment. It functions by using electrical resistance to generate heat, which is then transferred to the workload primarily through radiation within an enclosed chamber. Its primary advantages are its operational simplicity, high temperature uniformity, and wide-ranging applicability.

The true value of a box type resistance furnace lies in its role as a universal tool. Its straightforward design delivers reliable, uniform heating, making it an indispensable workhorse for countless research, development, and small-scale production tasks.

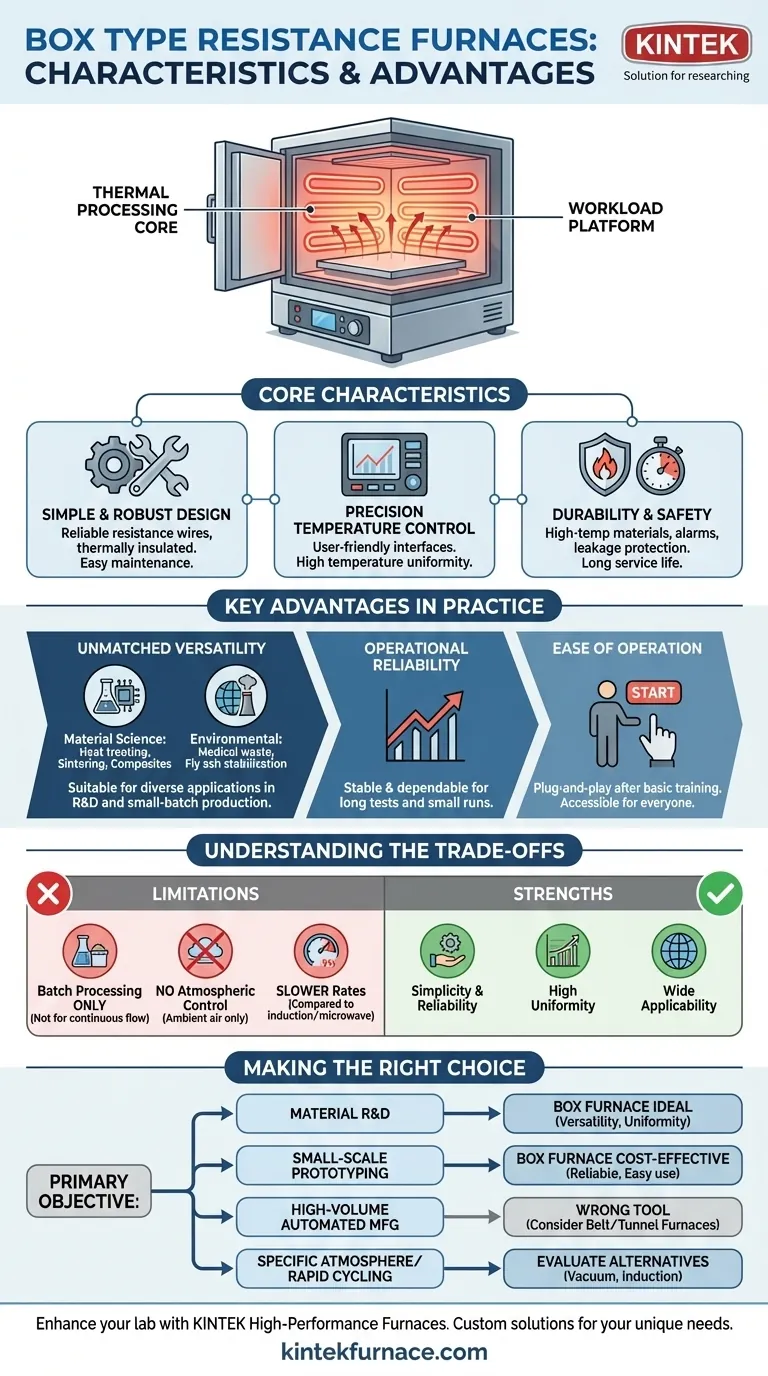

Deconstructing the Core Characteristics

A box furnace's effectiveness stems from a few key design principles that work in concert to provide a stable and controllable heating environment.

Simple and Robust Design

The furnace is built around heating elements, typically resistance wires, that are strategically placed within a thermally insulated chamber.

This fundamental structure is mechanically simple, which contributes to its reliability and ease of maintenance.

Precision Temperature Control

Modern box furnaces are equipped with user-friendly control interfaces. These allow operators to easily set, start, and stop heating cycles.

Crucially, the enclosed "box" design promotes high temperature uniformity, ensuring that the entire workload is exposed to a consistent thermal environment.

Built for Durability and Safety

These furnaces are constructed with high-quality insulation and heating materials chosen for their high temperature and oxidation resistance.

This robust construction ensures a long service life and the ability to operate continuously, reducing production downtime. Standard safety features like over-temperature alarms and leakage protection are included to protect both the operator and the equipment.

Key Advantages in Practice

The design characteristics of a box furnace translate directly into tangible benefits for laboratories and industrial facilities.

Unmatched Versatility

Its simple, controllable heating makes the furnace suitable for a vast array of applications.

In material science, it is used for heat treating metals (annealing, quenching), sintering ceramics, forming glass, and processing advanced composites like carbon fiber.

In environmental fields, it's used for the high-temperature pyrolysis of medical waste and the stabilization of fly ash by melting it into a safe, glassy state.

Operational Reliability

The combination of durable materials and a simple design results in a highly stable and dependable machine.

This reliability is critical for long-duration tests and small-batch production runs where equipment failure would be costly and disruptive.

Ease of Operation

A key advantage is its accessibility. After basic training, nearly any operator can manage heating cycles effectively.

This "plug-and-play" nature lowers the barrier to entry for sophisticated thermal processing, making it a staple in academic and R&D settings.

Understanding the Trade-offs

No single piece of equipment is perfect for every task. The box furnace's strengths in simplicity and versatility come with inherent limitations.

Batch Processing vs. Continuous Flow

The fundamental design of a box furnace is for batch processing. You load a part, run a cycle, cool it down, and unload it.

It is inherently unsuitable for high-volume, continuous production lines, where a tunnel or belt furnace would be more appropriate.

Atmospheric Control

A standard box furnace operates in ambient air. While sufficient for many tasks, it is not designed for processes requiring a controlled atmosphere (e.g., vacuum or inert gas).

Achieving atmospheric control requires specialized and more complex furnace designs, moving away from the "simple" advantage of a basic box furnace.

Heating and Cooling Rates

While stable, the thermal mass of a well-insulated box furnace means that its heating and cooling rates can be slower than more specialized equipment like induction or microwave furnaces.

This can be a limitation for processes that demand rapid thermal cycling.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on your primary objective.

- If your primary focus is material research and development: The box furnace is an ideal choice due to its temperature uniformity, versatility for testing different materials, and operational simplicity.

- If your primary focus is small-scale production or prototyping: The furnace's reliability and ease of use make it a cost-effective solution for creating small batches of parts.

- If your primary focus is high-volume, automated manufacturing: The box furnace is the wrong tool; you should investigate continuous systems like belt or tunnel furnaces.

- If your primary focus is processes requiring a specific atmosphere or rapid cycling: You should evaluate specialized vacuum furnaces or alternative heating technologies like induction.

By understanding its core strengths and inherent limitations, you can leverage the box type resistance furnace as the powerful and versatile tool it was designed to be.

Summary Table:

| Characteristic/Advantage | Description |

|---|---|

| Simple and Robust Design | Uses resistance wires in an insulated chamber for reliability and easy maintenance. |

| Precision Temperature Control | Features user-friendly interfaces and high temperature uniformity for consistent results. |

| Durability and Safety | Built with high-temperature resistant materials and includes safety features like alarms. |

| Unmatched Versatility | Suitable for material science (e.g., annealing, sintering) and environmental applications (e.g., waste pyrolysis). |

| Operational Reliability | Dependable for long-duration tests and small-batch production with minimal downtime. |

| Ease of Operation | Accessible for operators after basic training, ideal for R&D and academic settings. |

| Limitations | Batch processing only, no atmospheric control, and slower heating/cooling rates compared to specialized equipment. |

Ready to enhance your lab's thermal processing with reliable, high-performance furnaces? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you're in material science, environmental research, or small-scale production, we can help you achieve superior results. Contact us today to discuss how our furnaces can benefit your specific applications!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- What is a Quartz Tube Furnace and what is its primary function? Essential for Real-Time Material Observation

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- What is the difference between an alumina tube furnace and a quartz tube furnace? Choose the Right Tube Furnace for Your Lab

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab