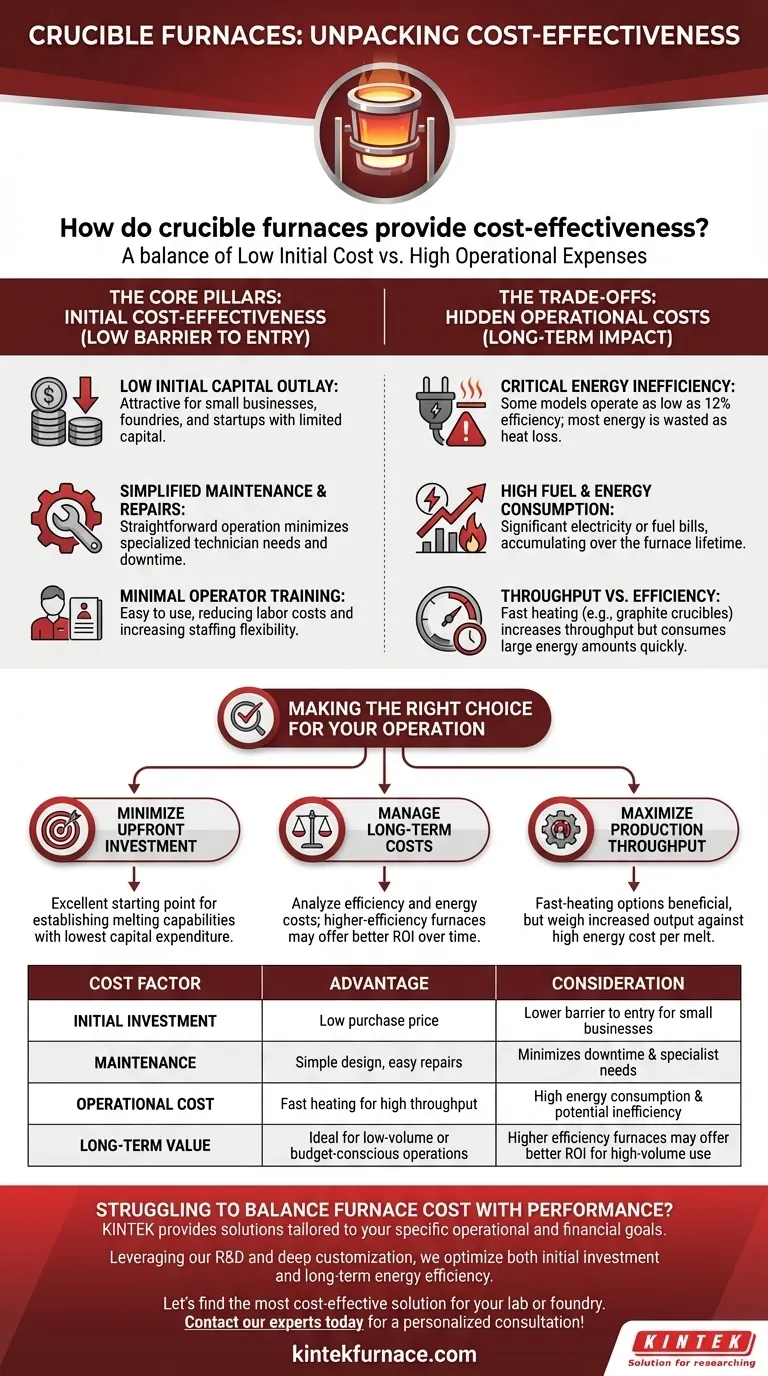

Crucible furnaces are considered cost-effective primarily due to their low initial purchase price and straightforward maintenance requirements. This makes them a highly accessible entry point for small-scale operations, startups, and businesses with limited capital who need to begin metal melting operations without a significant upfront investment.

The true cost-effectiveness of a crucible furnace is a balance. While it offers low initial and maintenance costs, this is often traded for poor energy efficiency, which can lead to significantly higher long-term operational expenses.

The Core Pillars of Initial Cost-Effectiveness

For many businesses, the most significant financial hurdle is the initial capital required to get started. Crucible furnaces excel in lowering this barrier.

Low Initial Capital Outlay

The primary financial advantage of a crucible furnace is its relatively low purchase price compared to other furnace technologies. This makes it an attractive option for small businesses, foundries, and startups that need to manage their budget carefully.

Simplified Maintenance and Repairs

Crucible furnaces are designed for straightforward operation and maintenance. This simplicity reduces the need for specialized technicians, minimizes costly downtime, and ensures performance can be consistently maintained over time with minimal expense.

Minimal Operator Training

The ease of use means that operators require minimal training or specialized skills. This directly translates to lower labor costs and greater flexibility in staffing, as new personnel can be brought up to speed quickly.

Understanding the Trade-offs: Hidden Operational Costs

While the upfront cost is low, the day-to-day running cost can be a significant, often overlooked, financial factor. A complete cost analysis must account for the furnace's efficiency.

The Critical Factor of Energy Inefficiency

A major drawback of many crucible furnace models is their poor energy efficiency. Some units may operate at an efficiency as low as 12%, meaning the vast majority of the energy consumed is wasted as heat loss rather than used to melt the metal.

This inefficiency directly leads to higher fuel or electricity bills for every single operation, a cost that accumulates significantly over the furnace's lifetime.

Fuel and Energy Consumption

While electric crucible furnaces reduce emissions, they can have very high energy costs. This is a critical consideration for any cost-sensitive operation, as high electricity prices can make an inefficient furnace financially unsustainable for high-volume production.

Throughput vs. Efficiency

Certain models, such as those using graphite crucibles, offer a very fast heating speed. This can reduce processing time and increase the number of melts you can perform in a day. However, this faster speed does not change the underlying inefficiency; it simply consumes a large amount of energy in a shorter period.

Making the Right Choice for Your Operation

Choosing a furnace requires looking beyond the sticker price and analyzing how it aligns with your specific operational goals.

- If your primary focus is minimizing upfront investment: A crucible furnace is an excellent starting point, allowing you to establish melting capabilities with the lowest possible capital expenditure.

- If your primary focus is managing long-term operational costs: You must carefully analyze the furnace's efficiency rating and your local energy costs, as a more expensive but efficient furnace may save you money in the long run.

- If your primary focus is maximizing production throughput: A fast-heating crucible furnace can be beneficial, but you must weigh the value of increased output against the high energy cost per melt.

Ultimately, your decision rests on understanding the critical balance between the low cost of ownership and the potentially high cost of operation.

Summary Table:

| Cost Factor | Advantage | Consideration |

|---|---|---|

| Initial Investment | Low purchase price | Lower barrier to entry for small businesses |

| Maintenance | Simple design, easy repairs | Minimizes downtime and specialist needs |

| Operational Cost | Fast heating for high throughput | High energy consumption & potential inefficiency |

| Long-Term Value | Ideal for low-volume or budget-conscious operations | Higher efficiency furnaces may offer better ROI for high-volume use |

Struggling to Balance Furnace Cost with Performance?

Choosing the right furnace is a critical decision that impacts your budget and productivity. At KINTEK, we don't just sell furnaces; we provide solutions tailored to your specific operational and financial goals.

Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse range of high-temperature furnaces, including advanced Crucible, Muffle, Tube, and Vacuum Furnaces. Our strong deep customization capability allows us to precisely engineer a system that optimizes both your initial investment and long-term energy efficiency.

Let's find the most cost-effective solution for your lab or foundry. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision