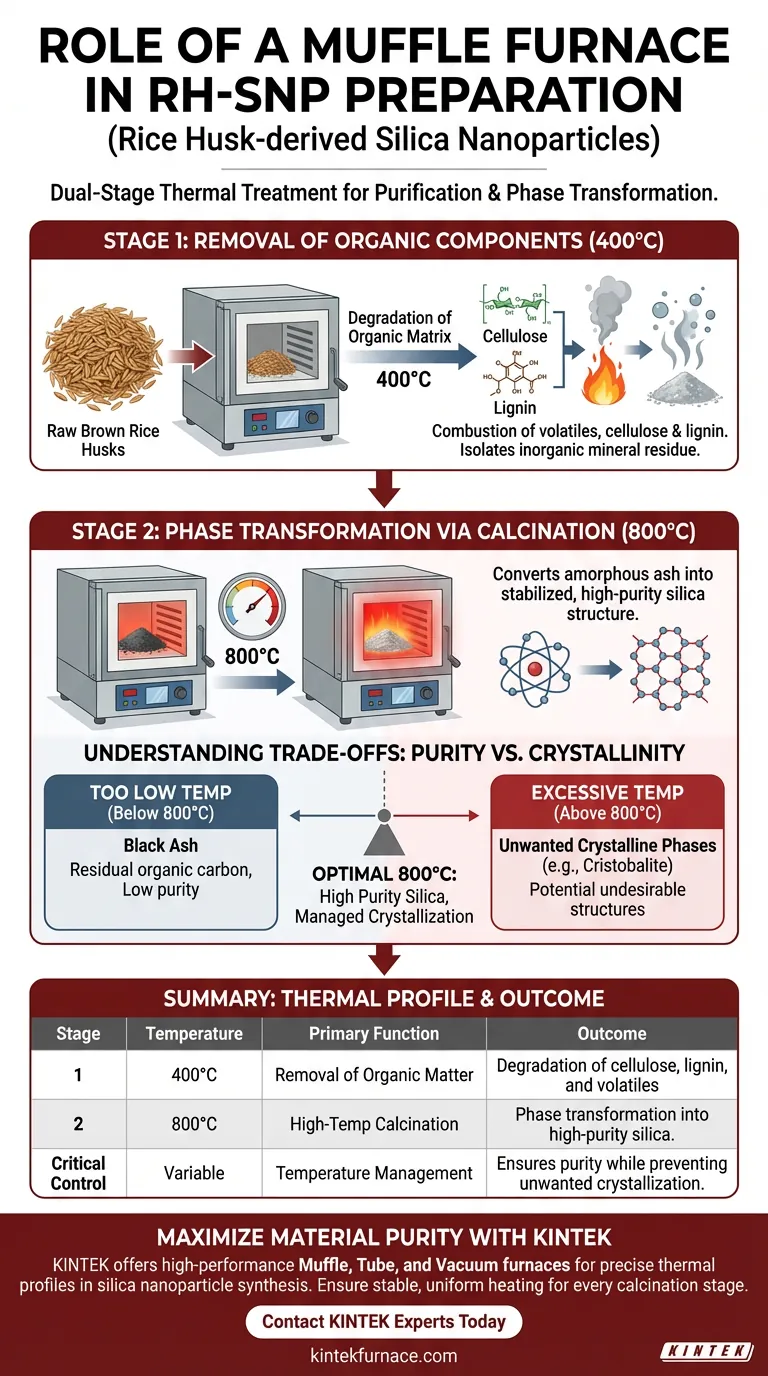

The primary role of a muffle furnace in the preparation of Rice Husk-derived Silica Nanoparticles (RH-SNP) is to execute a controlled, dual-stage thermal treatment essential for purification and phase transformation. Specifically, it performs an initial heat treatment at 400°C to degrade organic matter, followed by a calcination stage at 800°C to convert the remaining ash into a high-purity silica structure.

The muffle furnace serves as the purification engine, stripping away organic biological material and inducing the atomic rearrangement necessary to turn agricultural waste into high-value silica precursors.

The Dual-Stage Thermal Mechanism

The synthesis of RH-SNP is not a single-step heating process. It requires a distinct thermal profile to separate useful silicon from organic waste.

Stage 1: Removal of Organic Components

The first critical function of the furnace is the degradation of the rice husk's organic matrix.

The material typically undergoes heat treatment at 400°C.

At this temperature, the furnace facilitates the combustion of volatile organic components, such as cellulose and lignin. This is conceptually similar to "dry ashing," where the objective is to burn off carbon to isolate the inorganic mineral residue.

Stage 2: Phase Transformation via Calcination

Once the organics are removed, the furnace must reach significantly higher temperatures to alter the material's internal structure.

Calcination is performed at 800°C.

This high-temperature environment drives the phase transformation of the silicon components. It converts the amorphous ash into a stabilized, high-purity silica structure, providing the necessary chemical foundation for subsequent nano-structuring.

Understanding the Trade-offs

While the muffle furnace is the standard tool for this synthesis, the process relies heavily on precise temperature management.

Purity vs. Crystallinity

The temperature of 800°C is specific; it is high enough to ensure purity but must be controlled to manage crystallization.

If the temperature is too low, organic carbon residues will remain, resulting in "black ash" rather than white silica. This drastically reduces the purity of the final nanoparticles.

Conversely, excessive temperatures beyond the optimal range can force the silica into unwanted crystalline phases (such as cristobalite) which may be undesirable for certain nanoparticle applications that require amorphous structures.

Making the Right Choice for Your Goal

To achieve the best results in RH-SNP synthesis, you must tailor the furnace operation to your specific quality metrics.

- If your primary focus is eliminating contamination: Prioritize the duration and stability of the 400°C stage to ensure complete oxidation of all organic carbon before ramping up the heat.

- If your primary focus is structural integrity: Strictly monitor the ramp rate and dwell time at 800°C, as this calcination step dictates the final phase purity and suitability for nano-structuring.

Mastering the thermal profile of your muffle furnace is the single most important factor in converting raw rice husks into viable silica nanomaterials.

Summary Table:

| Stage | Temperature | Primary Function | Outcome |

|---|---|---|---|

| Stage 1 | 400°C | Removal of Organic Matter | Degradation of cellulose, lignin, and volatiles |

| Stage 2 | 800°C | High-Temp Calcination | Phase transformation into high-purity silica |

| Critical Control | Variable | Temperature Management | Ensures purity while preventing unwanted crystallization |

Maximize Your Material Purity with KINTEK

Precision is the difference between agricultural waste and high-value nanomaterials. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum furnaces designed to master the rigorous thermal profiles required for silica nanoparticle synthesis. Whether you need standard lab high-temp furnaces or customized systems tailored to your unique research needs, our technology ensures stable, uniform heating for every calcination stage.

Ready to elevate your lab's efficiency and material quality?

Visual Guide

References

- Lekan Taofeek Popoola, Sabitu Babatunde Olasupo. Photocatalytic degradation of methylene blue dye by magnetized TiO2-silica nanoparticles from rice husk. DOI: 10.1007/s13201-023-02052-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why are modern muffle furnaces considered energy-efficient? Discover Key Innovations for Lower Costs

- What are the benefits of high precision and control in a muffle furnace? Achieve Reliable Thermal Processing for Your Lab

- What is a hydrogen muffle furnace and how does it work? Precision Heating with Hydrogen for Oxide-Free Results

- What automation features do modern muffle furnaces include? Boost Precision and Efficiency in Your Lab

- How does the muffle furnace ensure uniform heating? Achieve Precise, Even Heat for Your Lab

- What should be done before using a muffle furnace for the first time or after a long period of inactivity? Essential Pre-Baking Guide

- What core roles does a muffle furnace play in the crystal growth of NaNbO3:Pr3+? Enhance Your Material Synthesis

- What makes muffle furnaces particularly useful for sensitive materials? Ensure Precision, Purity & Protection