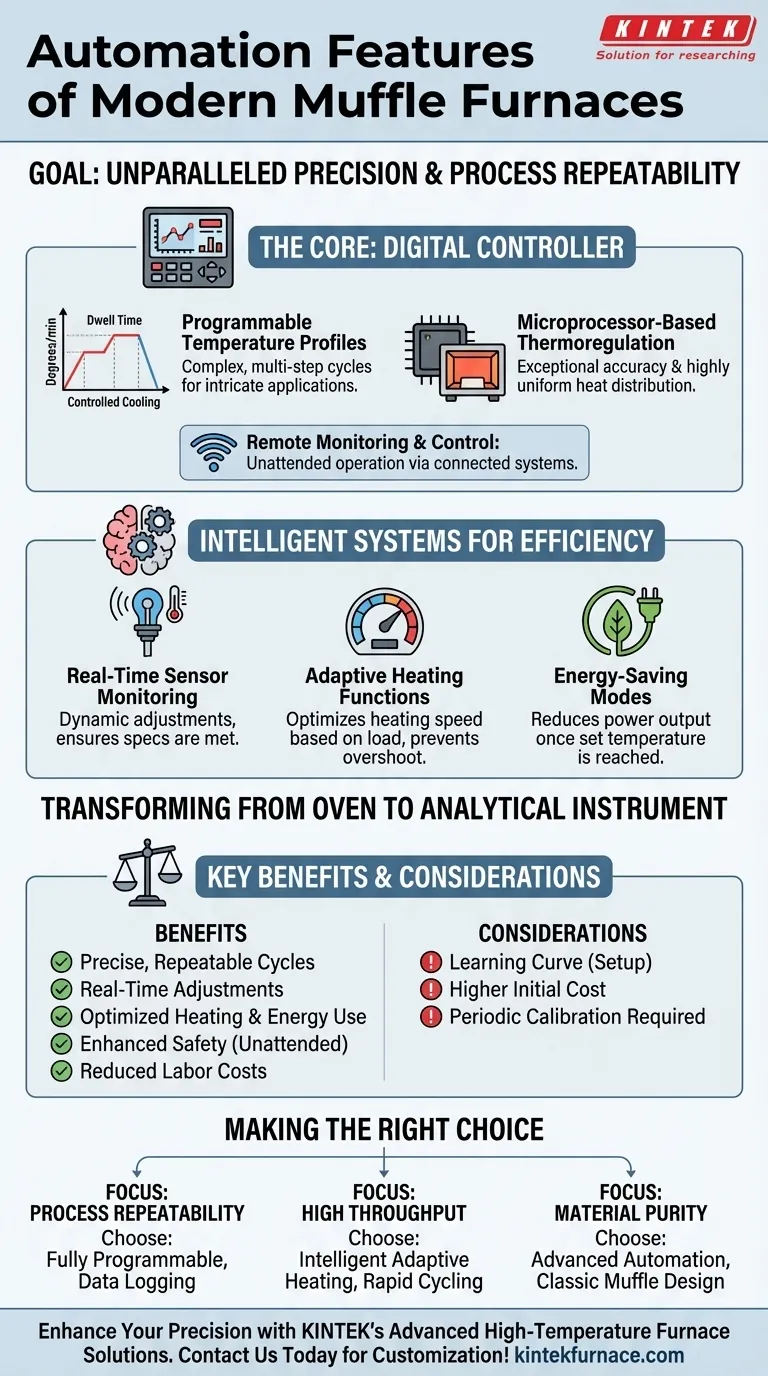

In short, modern muffle furnaces automate processes primarily through programmable digital controllers, integrated sensor systems, and intelligent heating functions. These features allow for precise, repeatable control over heating and cooling cycles, significantly reducing the need for manual oversight and minimizing human error.

The core purpose of this automation is to transform the muffle furnace from a simple high-temperature oven into a reliable and efficient analytical instrument. The goal is to achieve unparalleled precision and process repeatability while optimizing energy consumption.

The Core of Automation: The Digital Controller

The brain of a modern muffle furnace is its digital controller. This component replaces older analog dials and manual supervision, enabling sophisticated and unattended operation.

Programmable Temperature Profiles

Users can program complex, multi-step process cycles. This includes setting specific heating rates (degrees per minute), precise dwell times at target temperatures, and controlled cooling rates.

This level of control is critical for intricate metallurgical, ceramic, and chemical applications where the thermal history of the material dictates its final properties.

Microprocessor-Based Thermoregulation

Modern furnaces use microprocessor-controlled thermoregulators to maintain set temperatures with exceptional accuracy. These systems constantly monitor the chamber temperature and make micro-adjustments to the power supplied to the heating elements.

This ensures highly uniform heat distribution throughout the chamber, leading to consistent and reliable results for every sample in a batch.

Remote Monitoring and Control

Many advanced systems allow for remote monitoring and even operation via a connected computer or network. This feature simplifies continuous production processes and enhances safety by allowing operators to manage the furnace without being physically present.

Intelligent Systems for Efficiency and Performance

Beyond basic programming, modern furnaces incorporate intelligent features that actively optimize performance and energy use in real-time.

Real-Time Sensor Monitoring

Embedded sensors continuously track key parameters like temperature and, in some specialized models, pressure or gas flow. This data feed allows the controller to make dynamic adjustments, ensuring the process stays within tight specifications from start to finish.

Adaptive Heating Functions

Intelligent heating functions can automatically adjust the heating speed based on the load and the process requirements. This ensures the fastest possible ramp-up time without overshooting the target temperature, saving both time and energy.

Energy-Saving Modes

Advanced ceramic fiber insulation and high-efficiency heating elements (like silicon carbide) form the foundation of an energy-efficient design.

Automation builds on this with energy-saving modes that significantly reduce power output once a set temperature is reached, maintaining stability with minimal energy consumption.

Understanding the Trade-offs

While automation offers significant advantages, it is important to understand the associated considerations.

Complexity vs. Simplicity

The advanced functionality of a programmable controller introduces a learning curve. While it simplifies the execution of complex, repeatable tasks, the initial setup and programming can be more involved than operating a simple analog furnace.

Cost of Advanced Features

Furnaces equipped with sophisticated automation and high-precision sensors come at a higher initial purchase price. This investment must be weighed against the long-term benefits of improved process control, reduced labor costs, and greater energy efficiency.

Calibration and Maintenance

Digital controllers and sensors require periodic calibration to maintain their accuracy. This is a crucial maintenance step to ensure the furnace continues to perform as a precision instrument and that your results remain valid and traceable.

Making the Right Choice for Your Application

Selecting a furnace requires matching its automation capabilities to your specific operational goals.

- If your primary focus is process repeatability and documentation: Prioritize a furnace with a fully programmable controller and data logging capabilities to ensure consistent, traceable results.

- If your primary focus is high throughput and operational efficiency: Look for models with intelligent, adaptive heating functions, rapid cycling, and advanced energy-saving modes to minimize cycle times and utility costs.

- If your primary focus is material purity for sensitive analysis: Ensure the advanced automation is paired with a classic muffle design that effectively isolates the sample from heating element contaminants.

Ultimately, modern automation empowers you to treat the furnace not just as a heat source, but as a precise and reliable instrument for your work.

Summary Table:

| Automation Feature | Key Benefit |

|---|---|

| Programmable Digital Controllers | Enables precise, repeatable multi-step temperature cycles |

| Integrated Sensor Systems | Monitors temperature and other parameters for real-time adjustments |

| Intelligent Heating Functions | Optimizes heating rates and energy use based on load |

| Remote Monitoring and Control | Allows unattended operation and enhanced safety |

| Energy-Saving Modes | Reduces power consumption while maintaining temperature stability |

Enhance your laboratory's precision and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to discuss how our automation features can transform your thermal processes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO