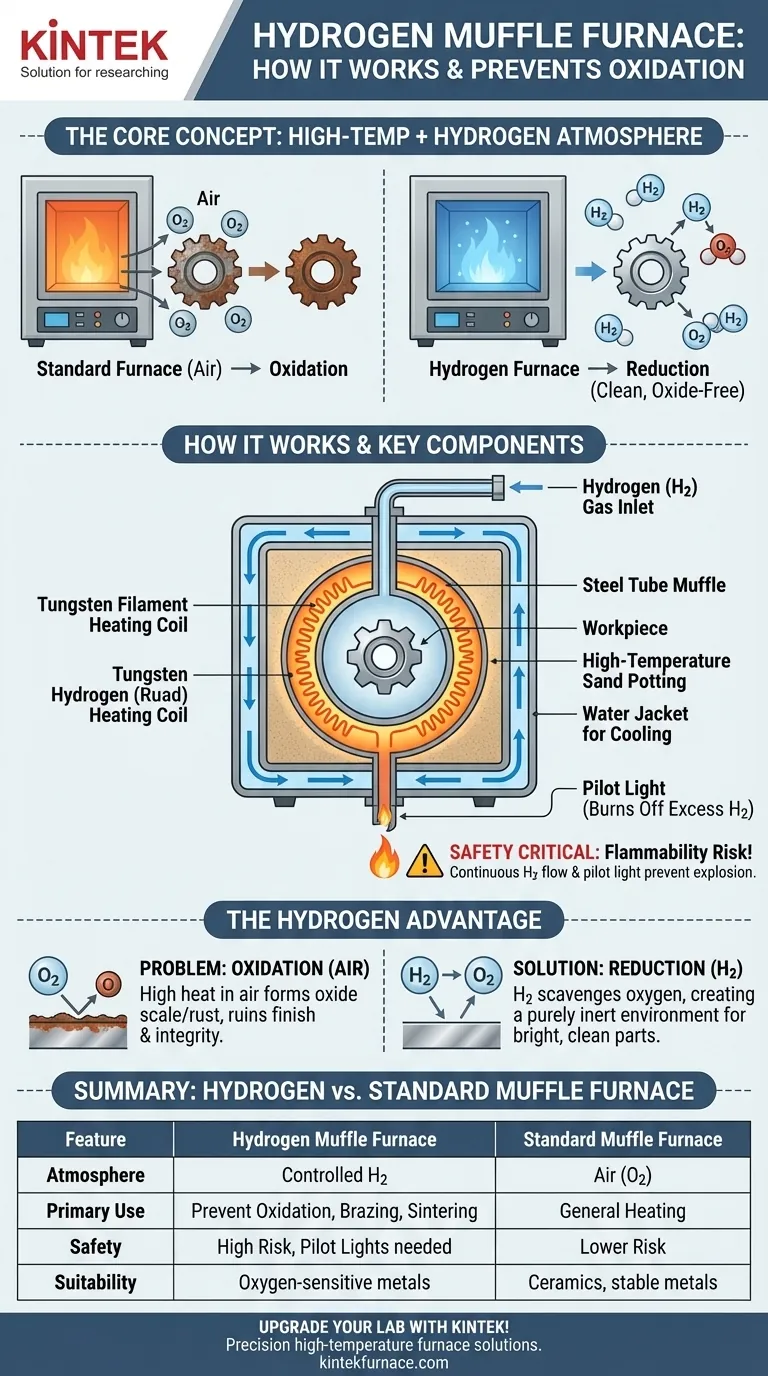

In essence, a hydrogen muffle furnace is a high-temperature oven that uses a controlled hydrogen gas atmosphere to heat materials. Unlike a standard furnace that operates in air, its primary purpose is to prevent oxidation and corrosion on the surface of the parts being processed, ensuring they remain clean and chemically unaltered by the high heat.

The critical distinction is not the heat itself, but the chemically active hydrogen atmosphere. This furnace is chosen specifically when the material being heated must be protected from oxygen, making it a tool for precision material processing rather than simple heating.

How a Standard Muffle Furnace Works

To understand what makes a hydrogen furnace unique, we must first understand the baseline technology. A standard muffle furnace is a cornerstone of high-temperature lab work and industrial processing.

The Muffle's Role: Indirect Heating

A muffle is a sealed, separated chamber made of a heat-resistant material. The workpiece is placed inside this muffle.

Heating elements are located outside the muffle, heating its walls. The heat then radiates into the chamber, ensuring the workpiece is heated evenly and is never in direct contact with the heating elements themselves.

Electrical Resistance Heating

These furnaces generate heat using electrical resistance elements, such as coils made of Kanthal or Nichrome wire. As electricity passes through them, they glow red-hot, reaching extremely high temperatures.

Uniform Temperature Control

A sophisticated control system with temperature sensors ensures the chamber reaches and maintains a precise temperature. This design eliminates hot spots and temperature gradients, which is critical for consistent results in material processing.

The Hydrogen Advantage: A Reducing Atmosphere

A hydrogen muffle furnace builds on this foundation but introduces a chemically active atmosphere to solve a specific problem: oxidation.

Why Use Hydrogen? The Problem of Oxidation

When most metals are heated to high temperatures in the presence of air, they react with oxygen. This forms an oxide layer—essentially a form of scale, tarnish, or rust—on the material's surface.

This oxidation can ruin the part's finish, compromise its structural integrity, or interfere with subsequent processes like brazing or soldering.

How Hydrogen Prevents Corrosion

Hydrogen is a powerful reducing agent. When it's introduced into the sealed muffle, it displaces all the air and, more importantly, scavenges any residual oxygen molecules.

By actively reacting with and removing oxygen, the hydrogen atmosphere ensures the metal part is heated in a purely oxygen-free environment, emerging from the process as bright and clean as it went in.

The Specific Construction

A common design consists of a steel tube that serves as the muffle. This tube is surrounded by a tungsten filament heating coil.

The entire assembly is often potted in high-temperature sand, which serves both to protect the fragile filament and to evenly transfer its heat to the steel tube muffle. A water jacket may be fitted around the exterior to allow for rapid, controlled cooling after the heating cycle is complete.

Understanding the Trade-offs and Safety Concerns

Using hydrogen introduces significant benefits but also demands strict safety protocols. The choice to use this technology is driven by necessity, not convenience.

The Extreme Flammability Risk

Hydrogen gas is highly flammable and can be explosive when mixed with air in certain concentrations. Filling a super-heated chamber with this gas creates an inherently hazardous environment.

Essential Safety Systems

Because of this risk, hydrogen furnaces are equipped with critical safety features. Hydrogen gas is continuously fed into the muffle, and any excess gas that exits must be handled safely.

This is why these furnaces have pilot lights at the gas outlets. These small flames immediately and safely burn off any escaping hydrogen, preventing it from accumulating and creating an explosion hazard.

Process Specialization

These furnaces are designed for specific applications like the brazing, sintering, or annealing of oxygen-sensitive metals. They are not general-purpose ovens due to their complexity and the safety requirements involved.

Making the Right Choice for Your Process

The decision to use a standard muffle furnace or a hydrogen variant is entirely dependent on your material and your desired outcome.

- If your primary focus is heating stable materials: For processes involving ceramics, glass, or metals where surface oxidation is not a concern, a standard air-atmosphere muffle furnace is the safer, simpler, and more cost-effective choice.

- If your primary focus is a pristine, oxide-free surface: For processes like brazing stainless steel or annealing sensitive alloys that must remain bright and uncontaminated, a hydrogen muffle furnace is non-negotiable.

Ultimately, selecting the right furnace depends on whether your process simply requires heat or demands a chemically controlled environment.

Summary Table:

| Feature | Hydrogen Muffle Furnace | Standard Muffle Furnace |

|---|---|---|

| Atmosphere | Controlled hydrogen gas | Air (oxygen present) |

| Primary Use | Prevent oxidation, brazing, sintering | General heating of stable materials |

| Safety | High (flammability risks, requires pilot lights) | Lower (standard safety measures) |

| Material Suitability | Oxygen-sensitive metals (e.g., stainless steel) | Ceramics, glass, oxidation-tolerant metals |

Upgrade your lab with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision equipment like Hydrogen Muffle Furnaces, Tube Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs for oxide-free processing and superior results. Contact us today to discuss how our furnaces can enhance your material processing efficiency and safety!

Visual Guide

Related Products

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What role do atmosphere furnaces play in new energy material R&D? Unlock Precision Synthesis for Batteries and Solar Cells

- What is the primary function of the circulation fan in a full-hydrogen bell-type furnace? Boost Heat Transfer Efficiency

- How is a box furnace used in sintering of metal powders? Achieve Dense, High-Strength Metal Parts

- What is the purpose of switching between N2 and H2 in electrical steel annealing? Master Atmosphere Control

- Why are high-temperature annealing furnaces and H2-N2 atmospheres required for oriented silicon steel research?