At its core, a muffle furnace ensures uniform heating through a principle of separation and radiation. The material being heated never touches the raw heating elements; instead, it sits inside a dedicated chamber, or "muffle," which absorbs heat from all sides and radiates it evenly, eliminating hot spots and ensuring a consistent thermal environment.

The uniformity of a muffle furnace is not the result of a single feature, but a design philosophy. It combines the physical isolation of the muffle chamber with strategically placed heating elements and precision electronic control to create a highly stable and homogenous heating environment.

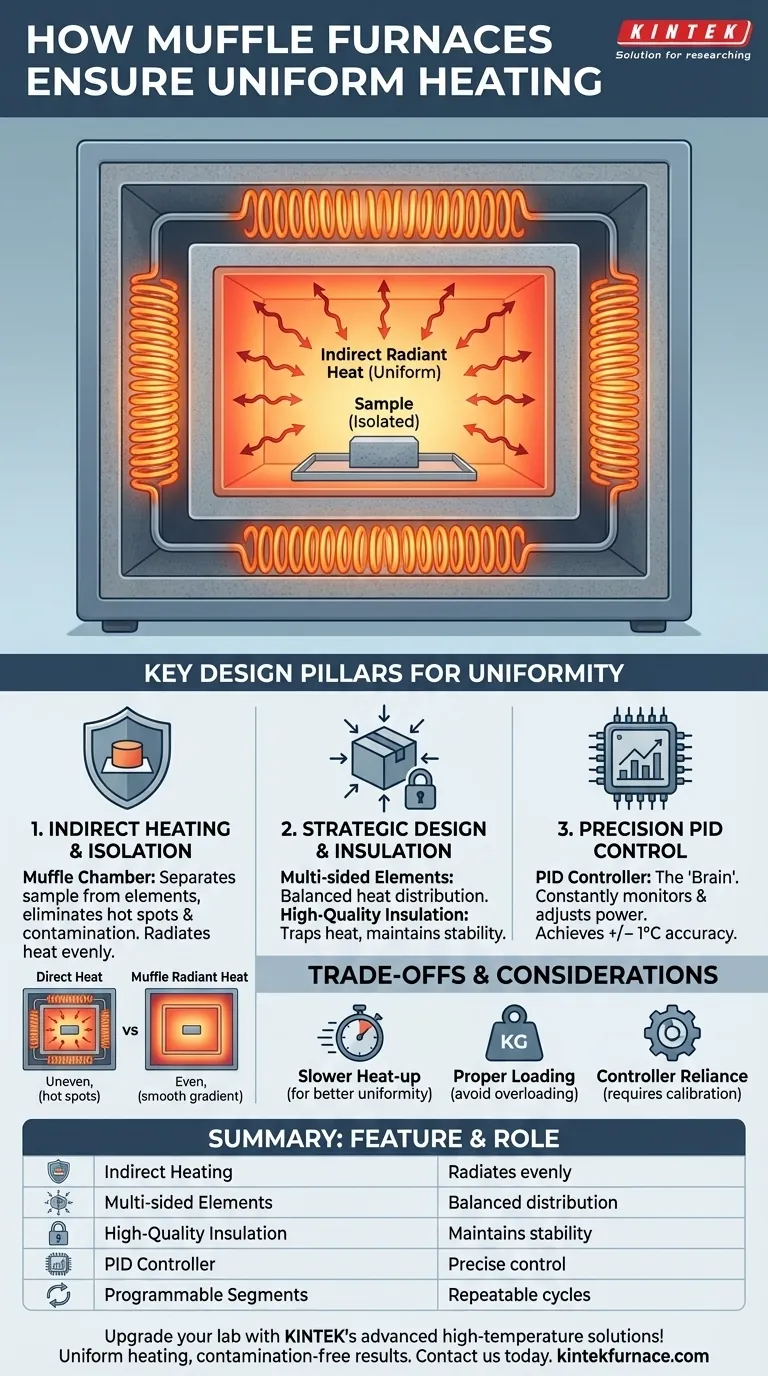

The Core Principle: Indirect Heating and Isolation

The defining feature of a muffle furnace is the "muffle" itself. Understanding this component is key to understanding its performance.

What is a "Muffle"?

A muffle is a separate, enclosed chamber made of high-temperature-resistant ceramic, such as alumina. The samples or materials you wish to heat are placed inside this chamber.

Crucially, the heating elements are located outside the muffle. They heat the exterior of the chamber, which in turn heats the space and materials inside it.

How Indirect Heating Creates Uniformity

This indirect heating method is the primary source of temperature uniformity. Instead of being exposed to the intense, direct heat of an element (like a toaster coil), the sample is bathed in radiant heat from the warm walls of the muffle.

This process is similar to how a convection oven cooks more evenly than a broiler. The heat is distributed throughout the entire volume of the chamber, minimizing the temperature gradients that cause inconsistent results.

The Benefit of Isolation: Preventing Contamination

This design provides a second, equally important benefit: it isolates the sample from the heating elements and any potential fuel or combustion byproducts.

This ensures the sample remains chemically pure and uncontaminated, which is absolutely critical for applications like chemical analysis, materials testing, or ashing where sample integrity is paramount.

Key Design Elements for Even Heat Distribution

Beyond the core principle, specific engineering choices enhance the furnace's ability to distribute heat evenly.

Strategic Placement of Heating Elements

To achieve rapid and uniform heating, manufacturers place open-coil heating elements on multiple sides of the muffle chamber, often on both sides and sometimes the top and bottom.

This multi-sided approach ensures the muffle itself heats up evenly, preventing one side from getting hotter than another and transferring that imbalance to the sample.

High-Quality Thermal Insulation

The entire assembly is housed within a heavily insulated casing. This insulation minimizes heat loss to the surrounding environment.

By trapping the heat energy, the furnace can maintain a stable temperature with less effort, further contributing to the stability and uniformity of the internal chamber.

The Role of Precision Electronic Control

The physical design creates the potential for uniformity, but sophisticated electronics are required to achieve and maintain it with precision.

The PID Controller: The Brain of the Furnace

Modern muffle furnaces use a PID (Proportional-Integral-Derivative) temperature controller. This is a smart feedback system that constantly monitors the chamber temperature via a thermocouple.

It intelligently adjusts the power sent to the heating elements to prevent overshooting the target temperature and to respond instantly to any minor heat fluctuations, holding the temperature remarkably steady.

Programmable Segments for Repeatability

Advanced controllers allow for programming multiple segments, including ramping (heating up at a set rate), dwelling (holding a temperature for a set time), and cooling.

This programmability ensures that every thermal cycle is identical, which is essential for repeatable experiments and consistent quality in production processes.

Achieving Precise Temperature Stability

The combination of a good PID controller and a well-designed chamber results in high accuracy. Many furnaces can achieve a temperature control accuracy of +/- 1°C.

This level of stability ensures that the entire process occurs within a very narrow and uniform temperature window.

Understanding the Trade-offs

No design is without its compromises. Understanding these limitations is key to using a muffle furnace effectively.

Heating Speed vs. Uniformity

Because the heat must first saturate the muffle before reaching the sample, muffle furnaces can have a slower heat-up time compared to direct-heating methods. This is the deliberate trade-off made to achieve superior temperature uniformity.

Chamber Size and Load Impact

The specified uniformity applies to an empty or properly loaded chamber. Overloading the furnace or placing a single, very large object inside can disrupt airflow and create its own temperature gradients, undermining the furnace's inherent design.

Reliance on Controller and Thermocouple

The system's accuracy is entirely dependent on the quality and calibration of the PID controller and the placement of the thermocouple. An improperly placed sensor or a poorly tuned controller will not deliver uniform results, regardless of the physical design.

Making the Right Choice for Your Application

Use these principles to evaluate a furnace based on what matters most for your work.

- If your primary focus is analytical purity and sample integrity: The muffle's isolation from combustion byproducts and heating elements is its most critical feature.

- If your primary focus is consistent material treatment (e.g., annealing): The combination of multi-sided heating elements and programmable PID control ensures repeatable thermal cycles.

- If your primary focus is high-precision temperature stability: The stated accuracy of the PID controller (e.g., +/- 1°C) is the key specification to evaluate.

By integrating these physical and electronic systems, a muffle furnace delivers the stable, uniform, and clean heating environment required for the most demanding technical applications.

Summary Table:

| Feature | Role in Uniform Heating |

|---|---|

| Indirect Heating | Radiates heat evenly from muffle walls, eliminating hot spots |

| Multi-sided Heating Elements | Ensures balanced heat distribution from all sides |

| High-Quality Insulation | Maintains stable temperature by minimizing heat loss |

| PID Controller | Provides precise temperature control and stability |

| Programmable Segments | Enables repeatable ramping, dwelling, and cooling cycles |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering uniform heating, contamination-free results, and enhanced efficiency. Contact us today to discuss how we can support your research and production goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating