Modern muffle furnaces achieve their energy efficiency through a strategic combination of advanced materials that minimize heat loss and intelligent control systems that optimize power consumption. Unlike older designs, they don't simply rely on brute force. Instead, they are engineered to generate heat effectively, trap it within the chamber, and use only the precise amount of energy required to maintain a stable temperature.

The core principle behind a modern furnace's efficiency is not a single component, but a holistic system. It combines high-grade insulation to contain thermal energy, efficient elements to generate it, and smart electronics to manage it, drastically reducing the wasted energy common in older equipment.

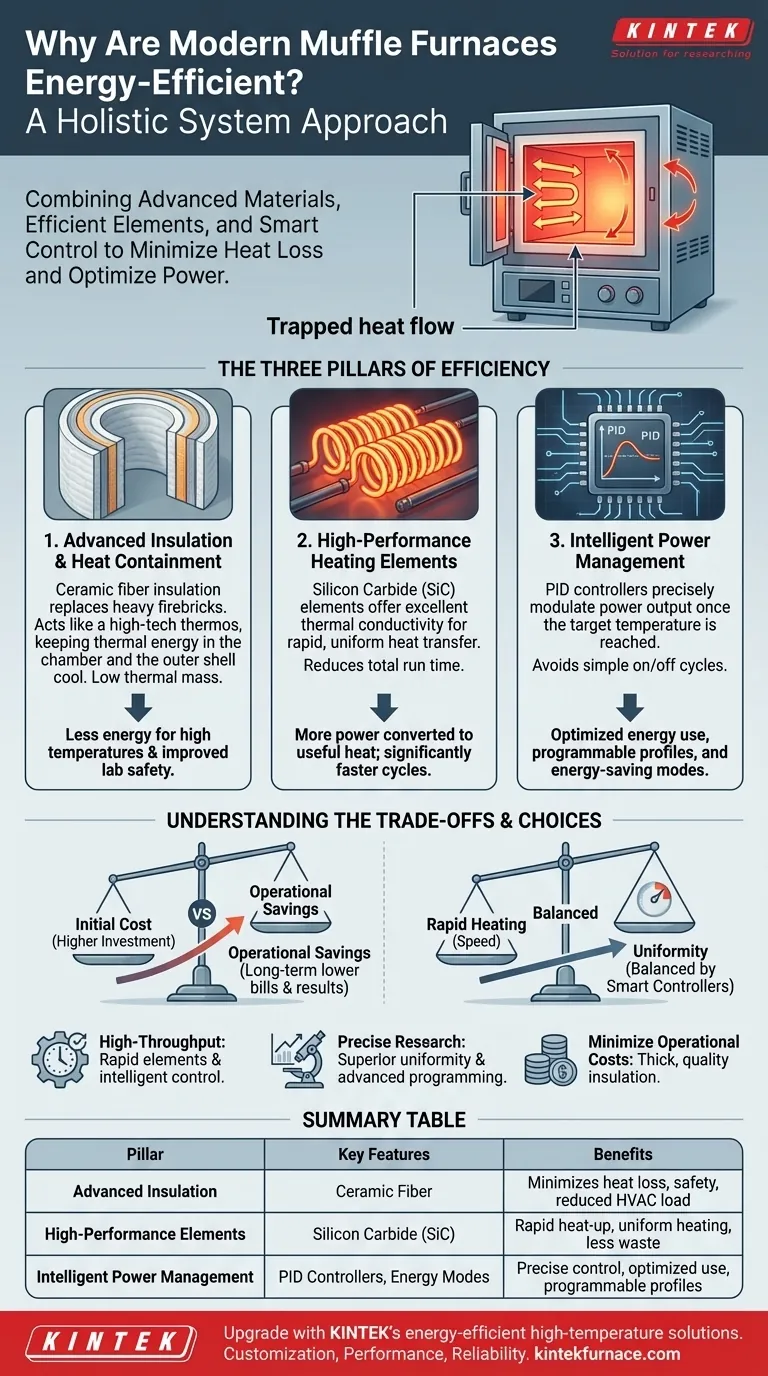

The Three Pillars of Muffle Furnace Efficiency

A furnace's energy consumption is a direct result of its ability to generate heat and, more importantly, to keep it. Modern designs excel by focusing on three critical areas.

Pillar 1: Advanced Insulation and Heat Containment

The single biggest factor in furnace efficiency is preventing heat from escaping. The goal is to keep the thermal energy inside the processing chamber.

Modern furnaces replace traditional heavy firebricks with advanced ceramic fiber insulation. This material has a very low thermal mass and excellent insulating properties, acting like a high-tech thermos for the furnace chamber.

This superior insulation means less energy is needed to reach and maintain high temperatures. It also keeps the outer shell of the furnace cooler, improving lab safety and reducing the heat load on HVAC systems.

Pillar 2: High-Performance Heating Elements

Efficiently converting electricity into usable heat is the second pillar. Modern furnaces often use silicon carbide (SiC) heating elements.

These elements have excellent thermal conductivity, allowing them to transfer heat to the chamber quickly and uniformly. This rapid heat-up capability reduces the total time the furnace needs to run at maximum power, saving significant energy during each cycle.

Their efficiency means more of the electrical power consumed is converted directly into useful heat within the chamber, with less being lost or wasted.

Pillar 3: Intelligent Power Management

This is the "brains" of the operation and a key differentiator for modern equipment. Instead of a simple on/off switch, these furnaces use sophisticated digital controllers.

These systems provide intelligent power adjustment, often through a PID (Proportional-Integral-Derivative) controller. Once the target temperature is reached, the controller precisely modulates the power output, delivering just enough energy to counteract the minimal heat loss.

Many models also feature energy-saving modes and programmable heating rates. This allows users to tailor the heating profile to the specific needs of their experiment, avoiding unnecessary energy use from excessively fast or prolonged heating.

Understanding the Trade-offs

While modern furnaces are highly efficient, it's important to understand the engineering compromises involved.

Initial Cost vs. Operational Savings

The advanced materials and sophisticated electronics in an energy-efficient furnace lead to a higher initial purchase price. This cost is an investment that pays off over the equipment's lifetime through significantly lower electricity bills and improved process results.

Heating Rate vs. Temperature Uniformity

Rapid heating is a hallmark of efficiency, as it minimizes runtime. However, an extremely aggressive heating rate can sometimes create temporary temperature gradients within the chamber. High-end controllers are specifically designed to balance this, ensuring both speed and excellent uniformity are achieved.

Specialized Design vs. Versatility

A furnace optimized for a single, repetitive process (like ashing) may be incredibly efficient for that task. However, its design may be less suitable for other applications requiring different heating profiles or atmospheres. Choosing a model means balancing specialized efficiency with general-purpose flexibility.

Making the Right Choice for Your Application

The practical benefits of an efficient muffle furnace extend beyond lower energy bills to include better process control, repeatability, and faster sample throughput.

- If your primary focus is high-throughput production: Prioritize models with rapid, efficient heating elements and intelligent controllers to minimize cycle times.

- If your primary focus is precise materials research: Look for superior temperature uniformity and advanced programming, which are direct results of an efficient and well-controlled design.

- If your primary focus is minimizing long-term operational costs: A furnace with thick, high-quality ceramic fiber insulation will provide the greatest return by minimizing passive heat loss over thousands of hours of operation.

By understanding these core principles, you can select a furnace that not only meets your technical requirements but also functions as a cost-effective and reliable long-term asset.

Summary Table:

| Pillar of Efficiency | Key Features | Benefits |

|---|---|---|

| Advanced Insulation | Ceramic fiber materials | Minimizes heat loss, improves safety, reduces HVAC load |

| High-Performance Heating Elements | Silicon carbide (SiC) | Rapid heat-up, uniform heating, less energy waste |

| Intelligent Power Management | PID controllers, energy-saving modes | Precise temperature control, optimized power use, programmable profiles |

Upgrade your laboratory with KINTEK's energy-efficient high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior performance, cost savings, and reliability. Contact us today to discuss how we can optimize your processes and reduce operational costs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency