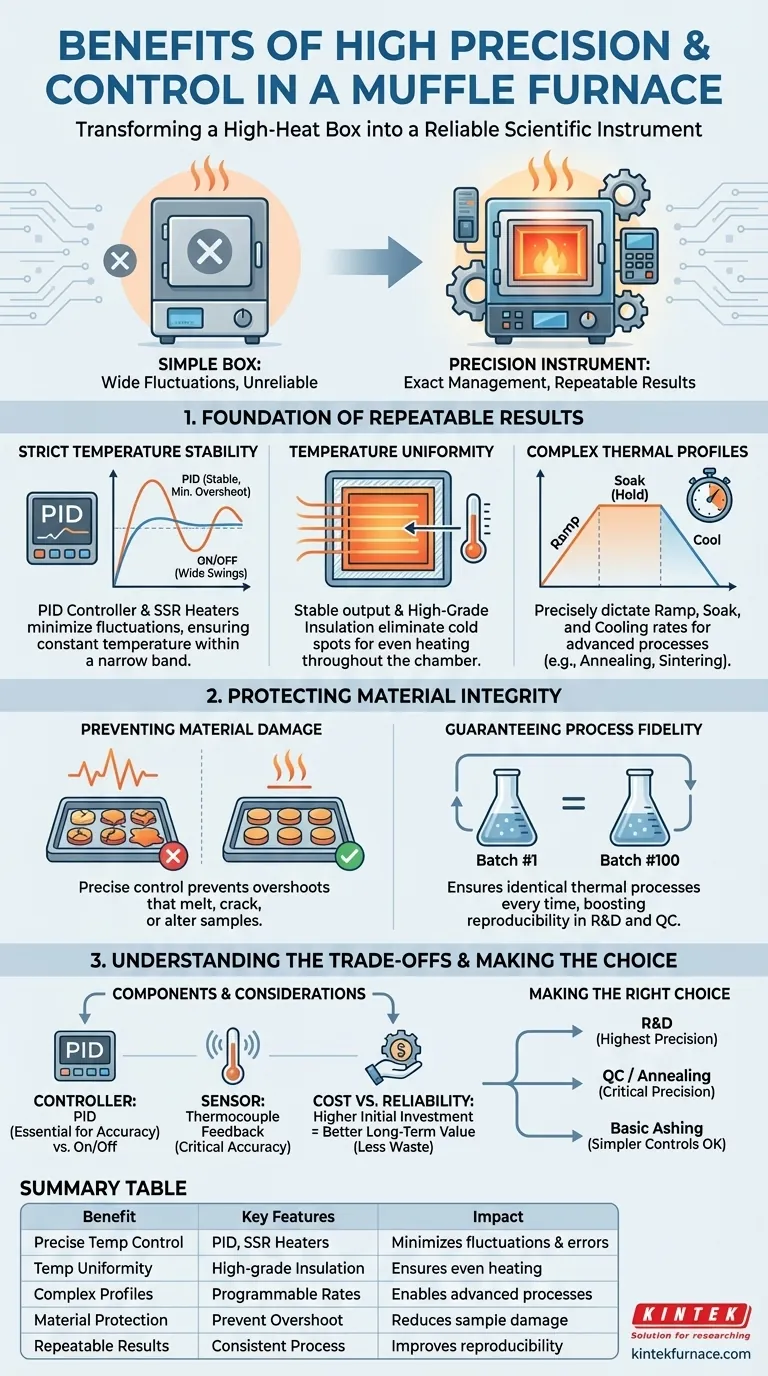

At its core, high precision and control transform a muffle furnace from a simple high-heat box into a reliable scientific instrument. This precision allows for exact temperature management with minimal fluctuations, ensuring the thermal process you design is the one your material actually experiences. This capability is the foundation for achieving accurate, repeatable results and preserving the integrity of your sample.

The true benefit of precision isn't just about reaching a target temperature; it's about guaranteeing that the entire thermal journey—heating, holding, and cooling—is perfectly controlled. This eliminates temperature as a source of error, leading to trustworthy outcomes in research, testing, and production.

The Foundation of Repeatable Results

High-quality thermal processing depends on eliminating as many variables as possible. Advanced control systems are designed to make temperature a constant you can rely on, not a variable you have to worry about.

Achieving Strict Temperature Stability

The most critical feature for precision is a PID (Proportional-Integral-Derivative) controller. Unlike a simple on/off thermostat that causes wide temperature swings, a PID controller constantly predicts and adjusts the power sent to the heating elements.

This system, often paired with fast-acting SSR-based (Solid State Relay) heaters, minimizes temperature overshoot and undershoot. The result is a highly stable temperature that stays within a very narrow band of your setpoint.

Ensuring Temperature Uniformity

A stable heat source is essential for achieving temperature uniformity throughout the furnace chamber. When the controller maintains a steady output, the heat can distribute evenly via convection and radiation.

This uniformity is further enhanced by high-grade insulation, such as dense ceramic or glass wool blankets, which prevent heat loss and eliminate cold spots, ensuring every part of your sample experiences the same temperature.

Enabling Complex Thermal Profiles

Many modern materials and processes require more than just a single temperature. Precision control allows for programmable thermal profiles.

This means you can precisely dictate the rate of temperature increase (ramp), the duration at a specific temperature (soak), and the cooling rate. This level of control is essential for complex processes like annealing, sintering, or advanced materials synthesis.

How Precision Protects Material Integrity

The ultimate goal of using a furnace is to modify a material in a desired way. Imprecise control can easily compromise or destroy your work.

Preventing Material Damage

Many materials are extremely sensitive to thermal shock or minor deviations from their ideal processing temperature. A temperature overshoot of even a few degrees can be the difference between success and failure.

Precise control prevents these overshoots, protecting your sample from being melted, cracked, or having its crystalline structure altered in an unintended way.

Guaranteeing Process Fidelity

In research and quality control, reproducibility is paramount. Precision ensures that the thermal process applied to batch #1 is identical to the one applied to batch #100.

By running the exact same thermal profile every time, you can confidently attribute any differences in outcome to other variables, not inconsistent heating. This dramatically improves the success rate of product development and testing.

Understanding the Trade-offs

While the benefits are clear, achieving high precision involves a system of components, and it's important to understand the associated considerations.

The Controller: PID vs. Simple On/Off

A furnace with a basic on/off controller will be less expensive but will never achieve true stability. For any application where accuracy matters, a PID controller is non-negotiable. An advanced, auto-tuning PID offers the best performance by automatically optimizing its settings for your specific furnace.

The Sensor: Feedback is Everything

The control system is only as good as the information it receives. The thermocouple is the sensor that reports the chamber temperature back to the controller. An accurate, properly placed sensor is critical for the entire system to function correctly.

The Cost vs. Reliability Equation

Furnaces equipped with advanced PID controllers, high-quality sensors, and superior insulation carry a higher upfront cost. However, this initial investment pays off through reduced sample failure, less wasted energy, and the ability to produce consistent, high-quality results over the long service life of the furnace.

Making the Right Choice for Your Application

Your specific goal dictates the level of precision you require.

- If your primary focus is research and development: You need the highest precision available to ensure your experimental results are valid, defensible, and repeatable.

- If your primary focus is quality control or annealing: Precision is critical for ensuring every part meets strict process specifications and industry standards.

- If your primary focus is basic ashing or general heating: A furnace with simpler controls may be sufficient and more cost-effective if minor temperature fluctuations do not impact your outcome.

Ultimately, investing in precision control is an investment in the certainty of your results.

Summary Table:

| Benefit | Key Features | Impact |

|---|---|---|

| Precise Temperature Control | PID controllers, SSR-based heaters | Minimizes fluctuations and errors |

| Temperature Uniformity | High-grade insulation, stable heat distribution | Ensures even heating across samples |

| Complex Thermal Profiles | Programmable ramp, soak, and cooling rates | Enables advanced processes like annealing |

| Material Integrity Protection | Prevents overshoot and thermal shock | Reduces sample damage and failure |

| Repeatable Results | Consistent thermal processes | Improves reproducibility in R&D and QC |

Upgrade your laboratory with KINTEK's precision high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide advanced solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met with reliable, repeatable results. Contact us today to discuss how our furnaces can enhance your thermal processing and drive success in your research or production!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment