Before its first use, or after any extended period of inactivity, a muffle furnace must be subjected to a pre-baking or drying cycle. This critical procedure involves heating the furnace slowly and holding it at specific temperatures for several hours. A general guideline is to heat for four hours at a temperature between 200°C and 600°C, but you must always consult your specific model's manual for the exact protocol.

The core reason for this procedure is not arbitrary. The furnace's ceramic and refractory insulation materials are porous and absorb atmospheric moisture. A controlled drying cycle is the only way to safely drive this moisture out as steam, preventing catastrophic damage to the furnace chamber and heating elements.

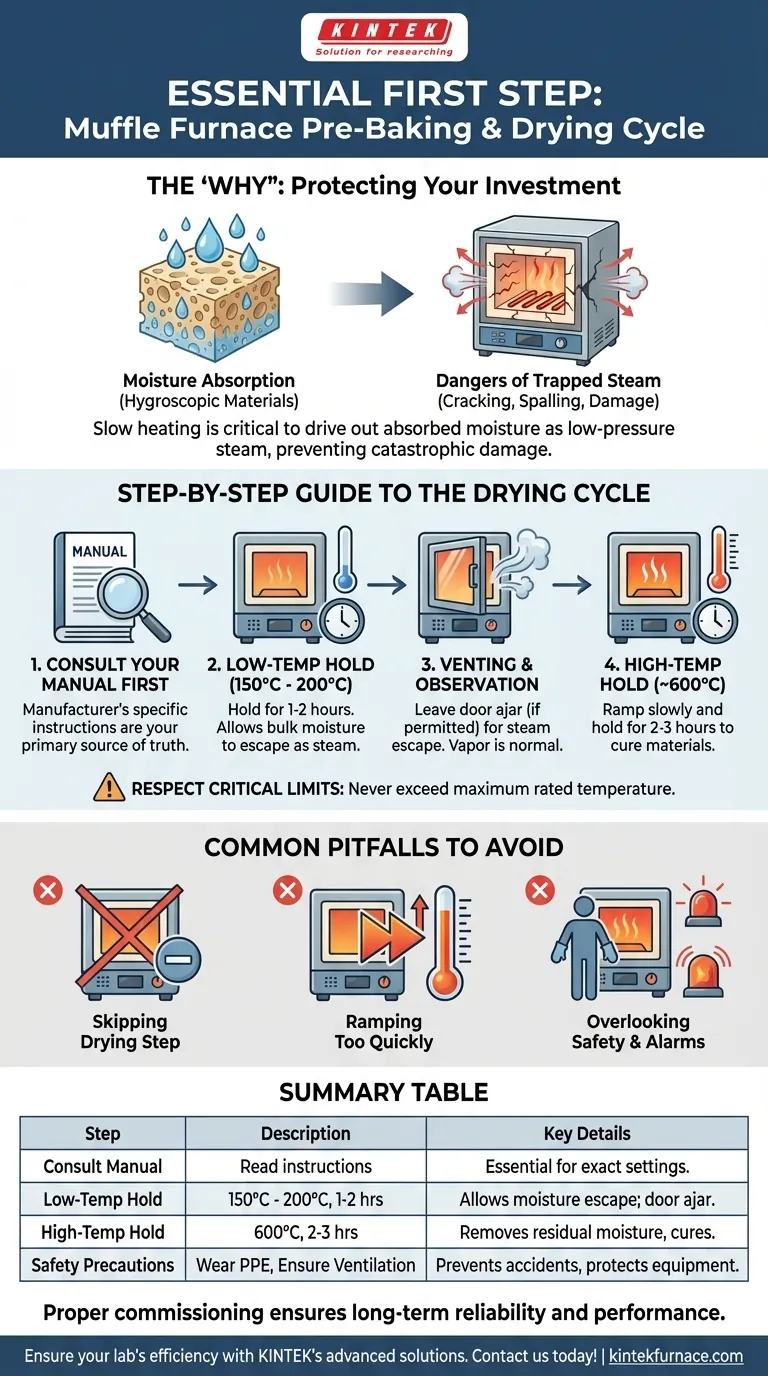

The "Why" Behind Pre-Baking: Protecting Your Investment

Properly commissioning your furnace is a foundational step that protects it from damage, ensures its longevity, and secures the accuracy of your future work. Skipping this process introduces significant risk.

Moisture Absorption in Refractory Materials

The high-performance insulation inside a muffle furnace is, by nature, hygroscopic—meaning it naturally absorbs water vapor from the air, much like a dry sponge.

When a furnace sits unused, whether in a warehouse before shipping or in a lab during a shutdown, its interior slowly becomes saturated with this moisture.

The Dangers of Trapped Steam

If you heat a moisture-laden furnace too quickly, the trapped water rapidly converts to high-pressure steam. With no easy escape route, this steam expansion exerts immense force on the surrounding material.

This can cause the refractory lining to crack, crumble, or "spall"—a process where flakes or layers of the material break off. In severe cases, it can permanently damage the fragile heating elements embedded within the insulation.

Ensuring Thermal Stability

Beyond removing moisture, a slow initial ramp-up allows all the furnace components to heat up and expand uniformly. This minimizes thermal stress on the joints, seals, and the furnace body itself, preventing premature wear and tear.

A Step-by-Step Guide to the Drying Cycle

While the manufacturer's guide is your primary source of truth, a general, safe procedure can be followed for most muffle furnaces.

Consult Your Manual First

Before starting, locate and read the manufacturer's specific instructions for the initial burn-in or drying cycle. Different insulation materials and furnace designs may require unique temperature ramps or hold times.

A General Drying Procedure

A conservative approach is always best. Start by setting the furnace to a low temperature, around 150°C to 200°C, and holding it for one to two hours. This allows the bulk of the moisture to turn to low-pressure steam and escape.

After the low-temperature hold, slowly ramp the temperature up to a higher setpoint, typically around 600°C, and hold for another two to three hours. This ensures any residual moisture is removed and the refractory materials are fully cured.

Venting and Observation

During the initial low-temperature phase, it is often recommended to leave the furnace door slightly ajar (if the design permits) to provide a clear path for the steam to exit. You may even see vapor coming out of the furnace, which is a normal sign that the process is working.

Respect Critical Temperature Limits

Under no circumstances should you ever exceed the furnace's maximum rated temperature. Doing so can cause immediate and irreversible damage to the heating elements and thermocouple, voiding your warranty.

Common Pitfalls to Avoid

Mistakes made during the first run can have lasting consequences. Awareness of these common errors is your best defense.

Skipping the Drying Step Entirely

The most severe mistake is assuming the furnace is ready to use out of the box for a high-temperature run. This is the primary cause of cracking and spalling in new furnaces.

Ramping Temperature Too Quickly

Impatience is the enemy. A fast ramp rate does not allow steam to escape gently, creating the damaging internal pressure discussed earlier. A slow, controlled heating cycle is an investment, not a waste of time.

Overlooking Basic Safety

The exterior of the furnace will become extremely hot. Always wear appropriate personal protective equipment (PPE), such as heat-resistant gloves, and be aware of potential fire hazards in the surrounding area. Ensure the room is well-ventilated.

Ignoring Alarms and Failsafes

Modern furnaces have safety features like over-temperature protection and circuit breakers. These are designed to protect you and the equipment. Never bypass them or ignore an alarm.

Applying This to Your Furnace

Your specific approach should be guided by your equipment's condition and your operating environment.

- If your primary focus is commissioning a brand-new furnace: Follow the manufacturer's burn-in procedure meticulously, as this is essential for equipment longevity and warranty compliance.

- If your primary focus is reactivating a stored furnace: Always perform a full, conservative drying cycle, starting at a low temperature to safely drive off any moisture accumulated during the shutdown.

- If your primary focus is routine operation in a humid climate: Be aware that your furnace will absorb moisture more quickly and may benefit from a brief, low-temperature drying run even after shorter periods of inactivity.

Properly commissioning your furnace is the foundational step that ensures its reliability, safety, and performance for years to come.

Summary Table:

| Step | Description | Key Details |

|---|---|---|

| Consult Manual | Read manufacturer's specific instructions | Essential for exact temperature and time settings |

| Low-Temp Hold | Heat at 150°C to 200°C for 1-2 hours | Allows moisture to escape as steam; door may be ajar |

| High-Temp Hold | Ramp to 600°C and hold for 2-3 hours | Removes residual moisture and cures materials |

| Safety Precautions | Wear PPE, ensure ventilation, do not bypass alarms | Prevents accidents and equipment damage |

Ensure your muffle furnace operates reliably with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how we can enhance your lab's efficiency and safety!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production