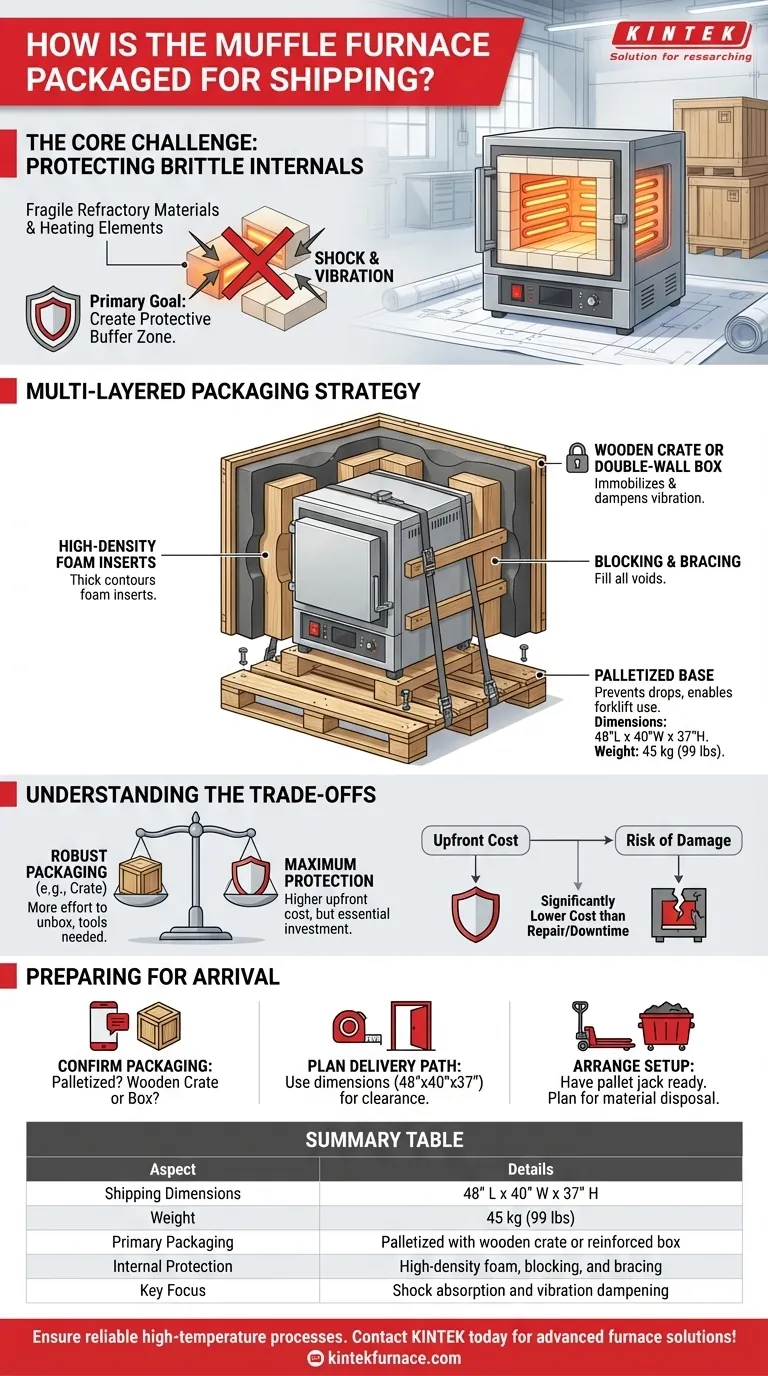

To ensure its safe arrival, the muffle furnace is packaged with a primary focus on preventing damage during storage and transportation. The packaging is designed to protect the integrity of the product, particularly its sensitive internal components, from the factory to your facility.

The core challenge in shipping a muffle furnace is protecting its brittle internal refractory materials and heating elements from shock and vibration. Consequently, the packaging strategy must prioritize stability and impact absorption above all else.

Key Considerations for Shipping a Muffle Furnace

The general statement that the furnace is "carefully handled" points to a multi-layered packaging strategy. This is standard for any piece of sensitive, high-value laboratory or industrial equipment.

Protecting Fragile Internal Components

A muffle furnace contains heating elements and ceramic-based insulation. These materials are excellent for thermal management but can be brittle and susceptible to cracking from sharp impacts or excessive vibration.

The packaging's primary job is to create a protective buffer zone around the unit to absorb these external forces.

Managing Weight and Dimensions

The specified shipping dimensions (48" L x 40" W x 37" H) indicate a substantial piece of equipment. At a weight of 45 kg (approximately 99 lbs), the unit is too heavy and bulky for standard parcel shipment.

This size and weight almost always necessitate shipping the furnace on a pallet. Palletizing prevents the unit from being dropped or mishandled by manual lifting and allows it to be moved safely with a pallet jack or forklift.

Standard Industry Packaging Methods

While the exact materials are not listed, equipment of this nature is typically secured using a combination of methods.

This often involves a heavy-duty, double-wall corrugated box or a full wooden crate. The furnace itself is usually bolted or strapped to the pallet base to prevent any movement within the outer container.

Preventing Internal Shock and Vibration

To stop the furnace from shifting and to dampen vibration, high-density foam inserts, blocking, and bracing are used. These materials fill any voids within the crate and conform to the furnace's shape, effectively immobilizing it.

Understanding the Trade-offs

Properly packaging a muffle furnace involves balancing protection against logistical realities. Understanding these trade-offs helps you prepare for receiving the shipment.

Protection vs. Unpacking Effort

Extremely robust packaging, such as a fully enclosed wooden crate, offers maximum protection. However, it also requires more tools (like a pry bar or drill) and effort to unbox.

Be prepared for a more involved unpacking process than with typical packages. This is a positive sign, indicating the manufacturer has prioritized the equipment's safety.

Cost vs. Risk of Damage

While robust crating adds to the upfront shipping cost, it is an essential investment. The cost of repairing or replacing a furnace damaged in transit—including the resulting project delays and downtime—is significantly higher than the cost of proper packaging.

Preparing for Your Furnace's Arrival

Use the provided information to ensure a smooth and safe receiving process.

- If your primary concern is preventing damage: Confirm with the supplier if the unit is shipped on a pallet and whether it will be in a sealed wooden crate or a reinforced cardboard container.

- If your primary concern is logistics and receiving: Use the shipping dimensions (48"x40"x37") and weight (45 kg) to plan the delivery path to its final location, ensuring doorways and hallways are wide enough.

- If your primary concern is setup: Arrange to have a pallet jack or other appropriate moving equipment on hand. Also, plan for the disposal of a significant amount of packaging material, such as a wooden pallet and foam inserts.

Proactive planning based on these packaging principles is the best way to ensure your equipment is ready for service immediately upon arrival.

Summary Table:

| Aspect | Details |

|---|---|

| Shipping Dimensions | 48" L x 40" W x 37" H |

| Weight | 45 kg (99 lbs) |

| Primary Packaging | Palletized with wooden crate or reinforced box |

| Internal Protection | High-density foam, blocking, and bracing |

| Key Focus | Shock absorption and vibration dampening |

Ensure your lab's high-temperature processes are supported by reliable equipment—contact KINTEK today to discuss your needs! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced solutions like Muffle, Tube, and Rotary Furnaces, along with deep customization to meet unique requirements. Reach out now for a consultation!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis