The primary function of a laboratory high-temperature furnace in nanocolloid research is to provide a controlled, constant-temperature environment for thermal conductivity testing. By precisely regulating the internal chamber, the furnace ensures that nanocolloid samples reach thermal equilibrium at specific temperature gradients. This stability allows researchers to accurately observe and measure how thermal conductivity changes as the temperature of the nanocolloid increases.

The high-temperature furnace serves as a "thermal anchor," eliminating external temperature fluctuations so that the relationship between heat and nanocolloid conductivity can be isolated and measured with high precision.

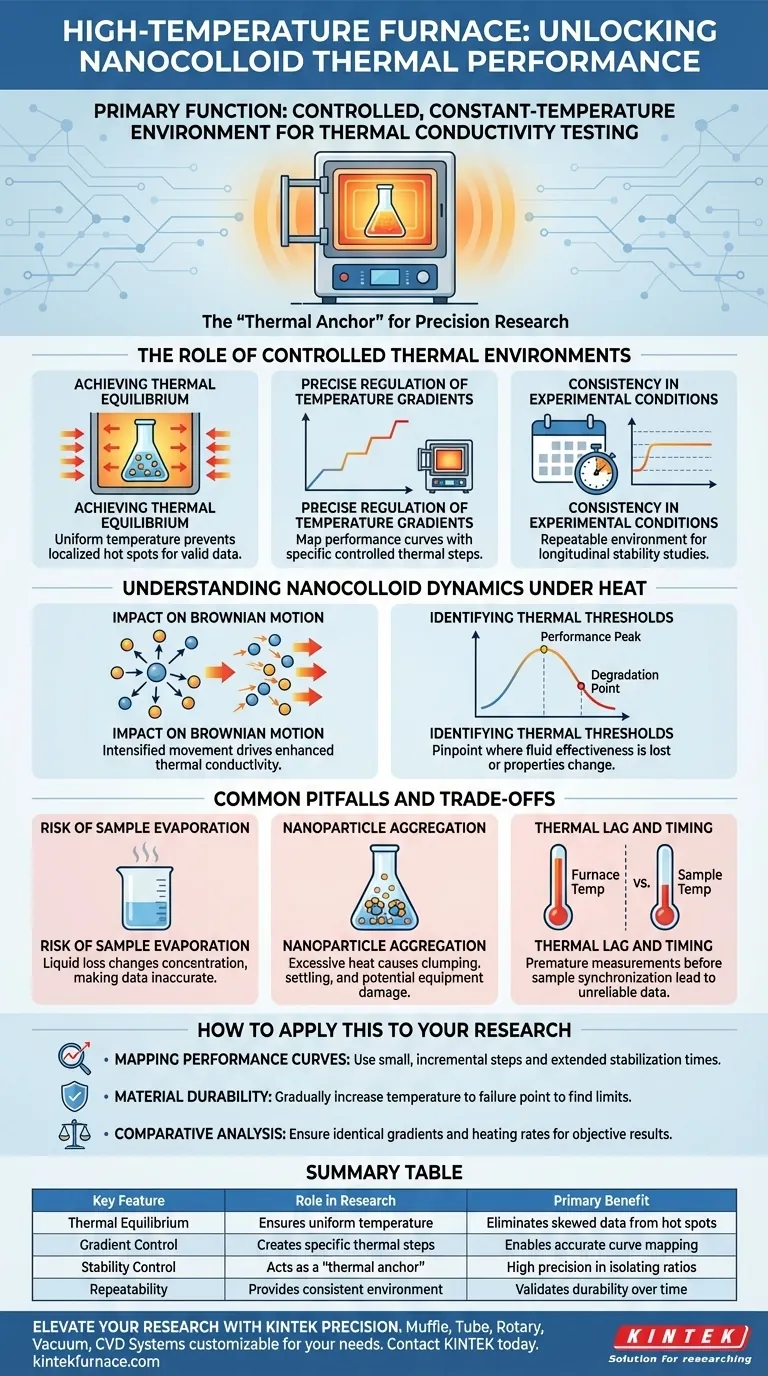

The Role of Controlled Thermal Environments

Achieving Thermal Equilibrium

For nanocolloid data to be valid, the sample must reach thermal equilibrium. This state ensures that the temperature is uniform throughout the liquid and the suspended nanoparticles, preventing localized "hot spots" from skewing the results.

Precise Regulation of Temperature Gradients

The furnace allows for the creation of specific temperature gradients. These controlled steps are necessary to map the performance curve of a nanocolloid, showing exactly how its heat-transfer capabilities evolve at different thermal stages.

Consistency in Experimental Conditions

High-temperature furnaces provide a repeatable environment. By maintaining a constant temperature over long periods, the furnace allows for longitudinal studies where the stability of the nanocolloid can be tested under sustained heat.

Understanding Nanocolloid Dynamics under Heat

Impact on Brownian Motion

As the furnace increases the temperature, the Brownian motion of the nanoparticles typically intensifies. This increased movement is a primary driver of enhanced thermal conductivity, and the furnace provides the stable platform needed to measure this phenomenon.

Identifying Thermal Thresholds

Every nanocolloid has a thermal threshold where its performance may peak or degrade. The furnace enables researchers to identify the exact point at which the fluid loses its effectiveness or begins to change its physical properties.

Common Pitfalls and Trade-offs

The Risk of Sample Evaporation

One major pitfall of high-temperature testing is the evaporation of the base fluid. If the liquid medium significantly decreases in volume, the concentration of nanoparticles changes, which renders the thermal conductivity data inaccurate.

Nanoparticle Aggregation

Excessive heat can cause nanoparticles to collide and stick together, a process known as aggregation. Once particles clump, they often settle out of the suspension, causing the nanocolloid to lose its unique thermal properties and potentially damaging testing equipment.

Thermal Lag and Timing

There is often a significant thermal lag between the furnace reaching a set temperature and the sample itself reaching that same temperature. Taking measurements too early, before the sample is fully synchronized with the furnace, leads to inconsistent and unreliable data.

How to Apply This to Your Research

To get the most out of high-temperature furnace testing, you must balance the need for high heat with the preservation of the colloid's delicate balance.

- If your primary focus is mapping performance curves: Use small, incremental temperature steps and allow for extended stabilization times to ensure the sample is at a true equilibrium.

- If your primary focus is material durability: Gradually increase the temperature to the point of failure to identify the specific aggregation or evaporation limits of your nanocolloid.

- If your primary focus is comparative analysis: Ensure that every sample is tested using the exact same temperature gradients and heating rates to maintain objective results.

Mastering the use of a high-temperature furnace is the only way to transform raw nanocolloid data into a definitive understanding of thermal performance.

Summary Table:

| Key Feature | Role in Nanocolloid Research | Primary Benefit |

|---|---|---|

| Thermal Equilibrium | Ensures uniform temperature across liquid and particles | Eliminates skewed data from localized hot spots |

| Gradient Control | Creates specific, incremental temperature steps | Enables accurate mapping of performance curves |

| Stability Control | Acts as a "thermal anchor" against fluctuations | High precision in isolating heat-conductivity ratios |

| Repeatability | Provides consistent environment for longitudinal tests | Validates material durability and stability over time |

Elevate Your Nanocolloid Research with KINTEK Precision

Unlock definitive thermal insights with laboratory furnaces designed for scientific excellence. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of your nanocolloid or high-temp material studies.

Whether you need precise thermal equilibrium or advanced temperature gradient control, our equipment ensures your data is accurate and repeatable. Contact KINTEK today to discuss your unique lab needs and let our experts help you build the perfect thermal solution.

Visual Guide

References

- Alina Adriana Minea, George Catalin Tofan. Discussion of Polyethylene Glycol Mixtures and PEG + MWCNT Nanocolloids’ Behavior in Thermal Applications. DOI: 10.3390/app15189898

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What key technologies were employed in the muffle furnace for environmental sample analysis? Achieve Accurate and Reliable Results

- What are the temperature and voltage specifications of the muffle furnace? Key Specs for Your Lab Needs

- What are the controller-based classifications of muffle furnaces? Choose the Right Control for Your Lab

- What are the general characteristics and advantages of box type resistance furnaces? Discover Versatile Heating Solutions for Your Lab

- What are the typical temperature ranges for muffle furnaces? Find the Perfect Fit for Your Lab

- What role does a high-temperature muffle furnace play in the electrodeposition of high-purity iron? Achieve Precision

- What should be done before first use or after long inactivity of a muffle furnace? Ensure Safety and Longevity with Proper Pre-Baking

- What is the function of a muffle furnace in ZnNPs synthesis? Achieve Pure, Crystalline Zinc Oxide