Before powering on a muffle furnace for the first time, or after it has been inactive for a long period, you must perform a mandatory pre-baking or drying cycle. This involves slowly heating the furnace for several hours at a moderate temperature, typically between 200°C and 600°C, to safely drive out any accumulated moisture from its internal components. This critical step prevents damage and ensures the furnace's long-term reliability.

This initial procedure is not simply a warm-up; it's a crucial conditioning step. Skipping it can lead to steam buildup within the furnace's refractory lining, causing cracks and catastrophic failure of the chamber.

The Critical Pre-Baking Procedure

Properly conditioning your furnace is the most important step you can take to protect your investment. The goal is to remove trapped moisture slowly and safely.

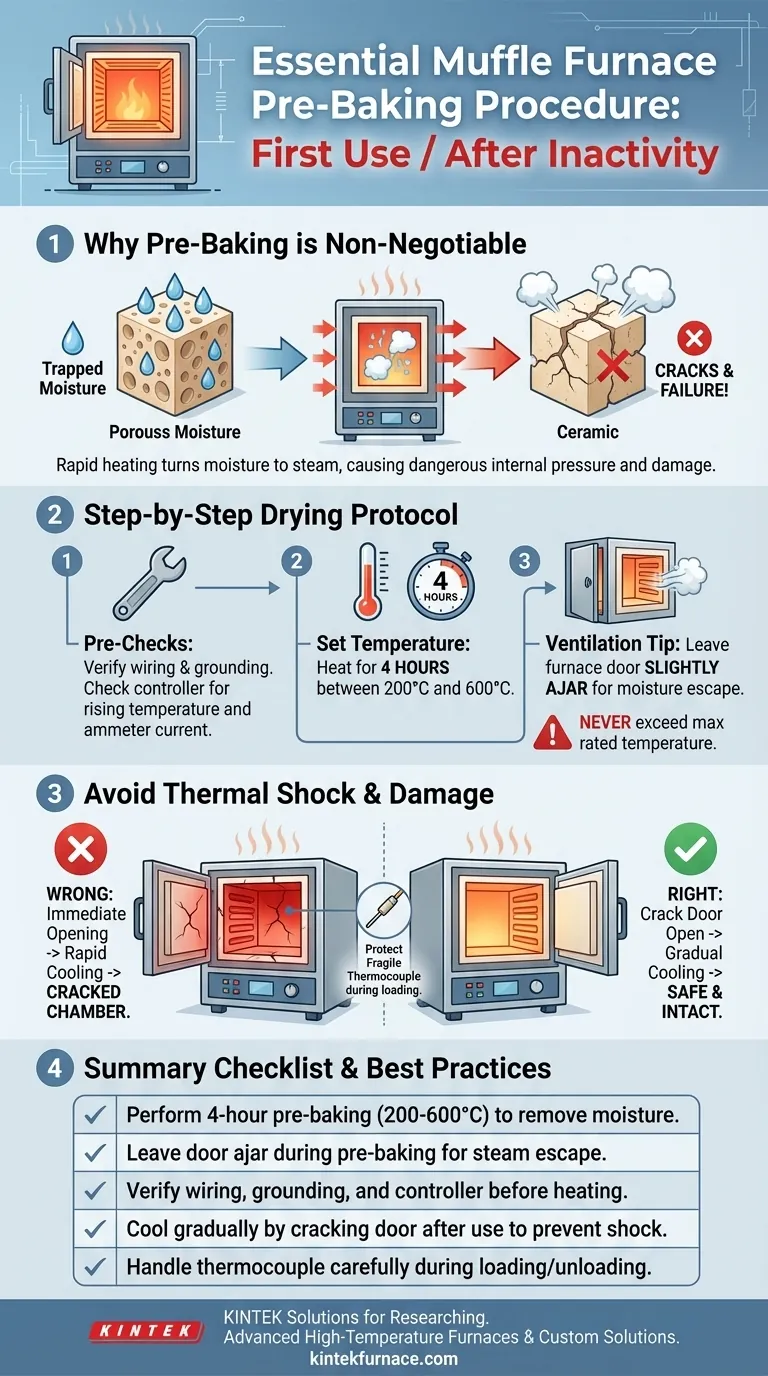

Why Pre-Baking is Non-Negotiable

The ceramic refractory materials that line a muffle furnace are porous. During long periods of inactivity, these materials naturally absorb moisture from the surrounding air.

When you heat the furnace rapidly, this trapped moisture turns to steam. If it can't escape gently, the steam pressure builds within the material, leading to spalling, cracking, or even a complete rupture of the furnace chamber.

Step-by-Step Drying Protocol

While you should always consult your specific model's manual, a common and effective general procedure is to heat the furnace for four hours at a temperature between 200°C and 600°C.

During this process, it is wise to leave the furnace door slightly ajar to allow the moisture an easy path to escape. Never exceed the furnace's maximum rated temperature.

Verifying Normal Operation

Before starting the drying cycle, confirm all wiring is correct and the unit is properly grounded.

Once you turn on the power, check that the controller and furnace are communicating. You should see the ammeter show a current reading and the temperature on the controller begin to rise steadily. This confirms the heating elements and control system are functioning.

Understanding the Pitfalls: Safety and Longevity

Beyond the initial drying, consistent operational discipline is key to safety and a long service life for the furnace.

The Danger of Thermal Shock

The most common mistake that damages a furnace is improper cooling. After a heating cycle is complete and the power is off, do not open the furnace door immediately.

The sudden rush of cool air creates thermal shock—a rapid temperature change that can easily crack the hot ceramic chamber.

The Correct Cooling Method

After turning off the power, open the furnace door just a small crack. This allows heat to escape and the temperature to drop more quickly but in a controlled manner.

Once the internal temperature has fallen significantly, you can fully open the door and remove your items with appropriate tongs and personal protective equipment.

Protecting Internal Components

Be mindful of the thermocouple. This temperature sensor often extends into the chamber and is very fragile, especially when hot. Avoid bumping or touching it when loading or unloading samples, as it can easily break.

Making the Right Choice for Your Goal

Adhering to the correct procedure is simple and ensures your equipment remains accurate and safe for years of use.

- If you are using the furnace for the first time or after long-term storage: You must perform the full, multi-hour pre-baking cycle to remove moisture.

- If you are loading samples for a routine run: Take care not to touch the thermocouple and ensure you do not exceed the furnace's rated temperature.

- If you have just completed a heating cycle: Always follow the gradual cooling procedure by cracking the door open before fully opening it to prevent thermal shock.

Following these fundamental operating principles is the key to maintaining a safe, reliable, and long-lasting muffle furnace.

Summary Table:

| Step | Action | Purpose |

|---|---|---|

| 1 | Perform pre-baking cycle (200°C-600°C for 4 hours) | Remove moisture to prevent cracks and failure |

| 2 | Leave door slightly ajar during pre-baking | Allow moisture to escape safely |

| 3 | Check wiring, grounding, and controller communication | Ensure proper operation before heating |

| 4 | Cool gradually by cracking door after use | Avoid thermal shock and damage |

| 5 | Handle thermocouple carefully during loading/unloading | Protect fragile components from breakage |

Ensure your muffle furnace operates safely and efficiently with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems, all with deep customization to meet your unique needs. Contact us today to discuss how our expertise can enhance your experimental outcomes and extend equipment lifespan!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How are Box Furnaces typically loaded? Manual Methods for Flexible Batch Processing

- What are some additional options available for Box Furnaces? Enhance Your Thermal Processing Efficiency

- What role do muffle furnaces play in materials research? Unlock Precise Heat Treatment for Your Lab

- How should materials be selected for use in a Muffle furnace? Optimize Your High-Temperature Processes

- What temperature range can a box furnace operate in? Find the Perfect Fit for Your Lab's Needs

- What are the limitations of a muffle furnace? Key Constraints for High-Temperature Applications

- What are the core functions of muffle furnaces in steel testing? Simulate Cooling & Microstructure Evolution

- What is the function of a box muffle furnace in nanoparticle stabilization? Optimize Active Ingredient Efficacy