To achieve accurate environmental sample analysis, a modern muffle furnace integrates three core technologies: efficient, high-temperature heating elements; precise temperature and atmosphere control systems; and a thermally isolated chamber. These elements work in concert to remove organic interference from samples by converting them to ash, ensuring the subsequent analysis of pollutants is both reliable and repeatable.

The primary challenge in environmental analysis is isolating inorganic pollutants from a complex organic matrix without altering the target analytes. A muffle furnace solves this not just with high heat, but through a controlled system where temperature uniformity, atmospheric purity, and thermal isolation prevent sample contamination and degradation.

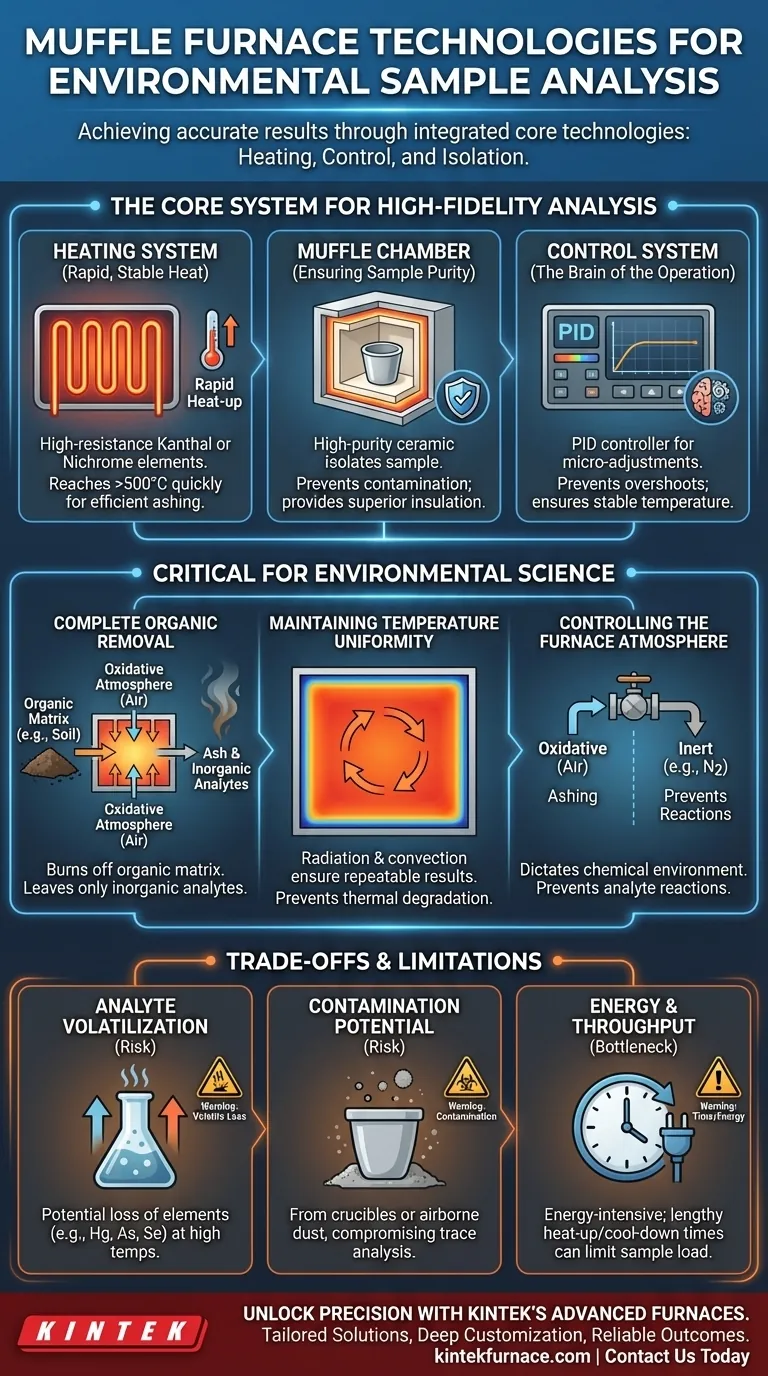

The Core System for High-Fidelity Analysis

A muffle furnace is more than a simple oven; it's a precision instrument where each component serves a critical function in preparing a sample for accurate measurement.

The Heating System: Delivering Rapid, Stable Heat

The furnace's power comes from high-resistance heating elements, often made of Kanthal or Nichrome alloys.

These elements are designed to quickly reach and maintain high temperatures, often exceeding 500°C, which is necessary for the ashing process in environmental samples. This efficiency reduces laboratory wait times and improves sample throughput.

The Muffle Chamber: Ensuring Sample Purity

The term "muffle" refers to the inner chamber, typically made of a high-purity ceramic. Its purpose is twofold.

First, it isolates the sample from the heating elements and any potential contaminants produced during combustion. This separation is vital for trace element analysis, where even minor impurities can skew results.

Second, it acts as a superior insulator, retaining heat and contributing to both temperature stability and energy efficiency.

The Control System: The Brain of the Operation

The most critical technology for analytical precision is the automatic temperature control system.

Modern furnaces use a Proportional-Integral-Derivative (PID) controller. This system continuously monitors the chamber temperature via sensors and makes micro-adjustments to the heating elements.

This prevents temperature overshoots that could cause volatile pollutants to be lost, and it ensures the temperature remains stable enough for the complete and even removal of organic material.

Why These Technologies are Critical for Environmental Science

The goal of using a muffle furnace in environmental analysis is to cleanly remove the organic "matrix" (like plant matter or hydrocarbons in soil) to accurately measure the inorganic pollutants left behind.

Achieving Complete Organic Removal

Many environmental samples—from soil to water sludge—are rich in organic substances that interfere with analytical techniques.

Heating the sample in an oxidative atmosphere (air) at a controlled high temperature ensures this organic matter is completely burned off, leaving behind only ash and the inorganic compounds of interest.

Maintaining Temperature Uniformity

Inconsistent heating is a major source of error. Hot spots can cause thermal degradation or the unintended loss of semi-volatile analytes, while cold spots result in incomplete ashing.

Furnaces achieve uniformity through a combination of thermal radiation and convection, ensuring the entire sample is exposed to the exact same temperature profile for repeatable results.

Controlling the Furnace Atmosphere

Precise atmosphere control allows the analyst to dictate the chemical environment.

While an oxidative atmosphere is common for ashing, an inert atmosphere (like nitrogen) may be required to prevent the target analyte from reacting with oxygen, which could change its chemical form and ruin the analysis.

Understanding the Trade-offs and Limitations

While essential, the use of a muffle furnace is not without its challenges. Acknowledging these limitations is key to developing robust analytical methods.

Risk of Analyte Volatilization

The primary trade-off of high-temperature ashing is the potential loss of volatile analytes.

Elements like mercury, arsenic, and selenium can turn into gas at temperatures used for ashing, leading to an underestimation of their concentration in the original sample. This requires careful temperature programming and validation.

Potential for Contamination

Although the muffle chamber provides isolation, contamination can still be introduced. The crucibles holding the samples or airborne dust entering the lab can carry contaminants that compromise trace analysis.

Energy Consumption and Throughput

Muffle furnaces are energy-intensive devices. The time required for the furnace to heat up, hold the target temperature, and cool down safely can be lengthy, creating a bottleneck in laboratories with high sample loads.

Making the Right Choice for Your Analysis

The optimal use of a muffle furnace depends directly on the specific analytes and sample matrix you are working with.

- If your primary focus is heavy metal analysis in soil: Prioritize a furnace with excellent temperature uniformity and a responsive PID controller to prevent the loss of semi-volatile metals like lead or cadmium.

- If your primary focus is determining organic matter content (Loss-on-Ignition): Ensure the furnace provides a reliable oxidative atmosphere and has adequate ventilation to facilitate complete and efficient combustion.

- If your primary focus is high-throughput screening: Consider the furnace's ramp rate (how fast it heats up) and its cooling efficiency, as these factors will directly dictate your overall sample processing time.

Ultimately, mastering the muffle furnace lies in understanding it as a precision instrument for sample purification, not just a high-temperature oven.

Summary Table:

| Technology | Key Function | Benefit for Analysis |

|---|---|---|

| High-Temperature Heating Elements | Rapidly heat to over 500°C for ashing | Ensures complete organic removal and faster processing |

| PID Control System | Precisely regulate temperature | Prevents analyte loss and maintains uniformity for repeatable results |

| Thermally Isolated Muffle Chamber | Isolate sample from contaminants | Protects sample purity in trace element analysis |

| Atmosphere Control | Manage oxidative or inert environments | Allows tailored conditions to prevent analyte reactions |

Unlock precision in your environmental analysis with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures your unique experimental requirements are met precisely, enhancing accuracy and efficiency. Contact us today to discuss how our furnaces can elevate your sample analysis and drive reliable outcomes!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?