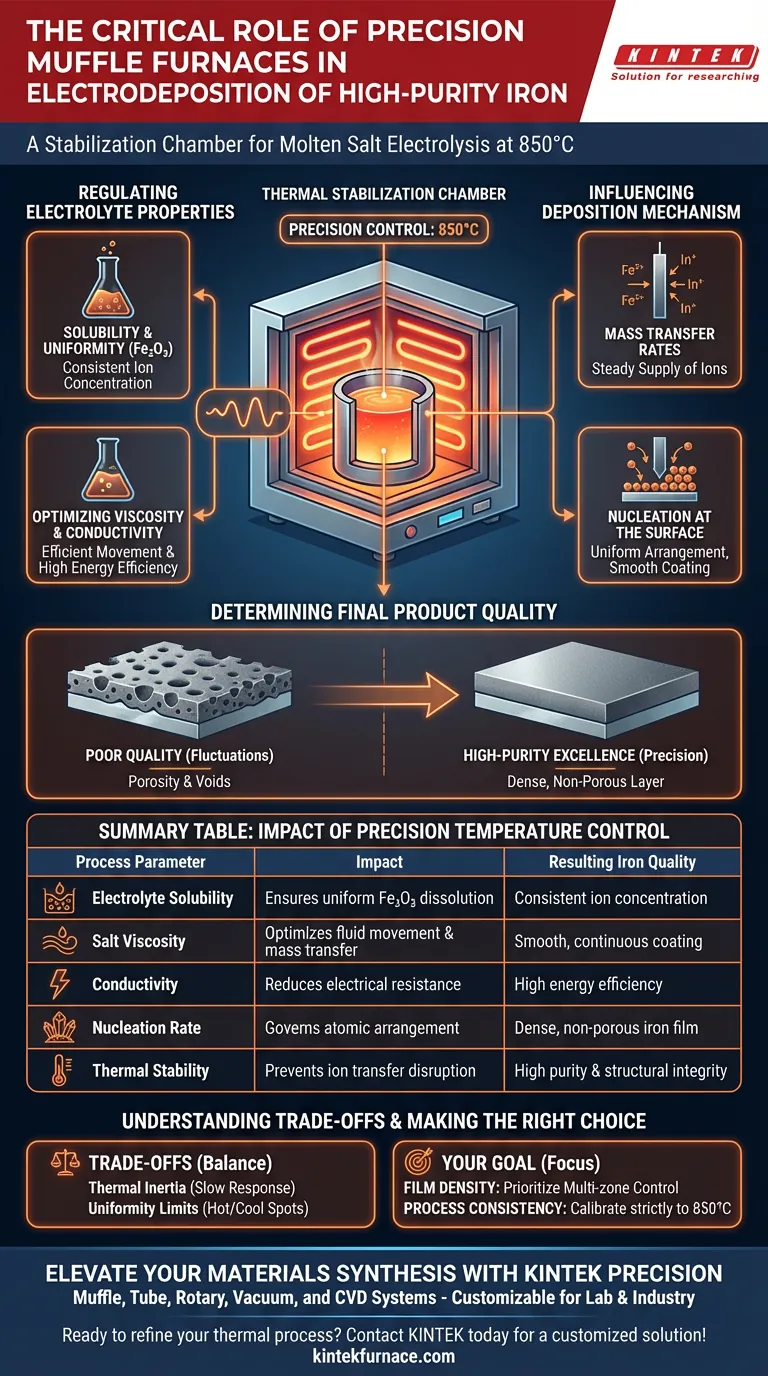

The high-temperature muffle furnace acts as the critical stabilization chamber for the electrodeposition of high-purity iron via molten salt electrolysis. Its primary role is to maintain a rigorous thermal baseline, typically at 850 degrees Celsius, which dictates the chemical behavior of the electrolyte and ensures the structural integrity of the final iron film.

Precision temperature control is the variable that connects electrolyte chemistry to final product quality. Without a stable thermal environment, fluctuations in viscosity and solubility disrupt ion transfer, resulting in inconsistent nucleation and poor-quality iron films.

Regulating Electrolyte Properties

The success of molten salt electrolysis relies entirely on the physical state of the salt mixture. The muffle furnace (or box resistance furnace) provides the isolated environment needed to manage these variables.

Controlling Solubility

The furnace must maintain a temperature high enough to ensure the proper solubility of Fe2O3 (iron oxide).

If the temperature fluctuates, the oxide may not dissolve uniformly. This leads to an inconsistent concentration of iron ions available for deposition.

Optimizing Viscosity and Conductivity

Temperature directly dictates the viscosity of the molten salt. A precisely heated environment ensures the salt remains fluid enough for efficient movement.

Simultaneously, the correct thermal set point maintains high electrical conductivity. This reduces resistance within the cell and improves the overall energy efficiency of the electrolysis.

Influencing the Deposition Mechanism

Beyond the state of the liquid salt, the thermal environment governs how the iron actually forms on the electrode.

Mass Transfer Rates

The rate at which iron ions travel through the molten salt to the cathode is the mass transfer rate.

The muffle furnace ensures this rate remains constant by preventing thermal gradients. A steady supply of ions is required to prevent defects in the growing film.

Nucleation at the Surface

Nucleation is the initial step where iron atoms arrange themselves into a solid structure on the electrode.

This process is highly sensitive to thermal energy. Precision control allows for uniform nucleation, which is the prerequisite for a smooth, continuous coating.

Determining Final Product Quality

The physical characteristics of the iron film are a direct reflection of the furnace's performance.

Ensuring Film Density

The ultimate goal is a dense, high-purity iron film.

Fluctuations in the furnace environment can lead to porosity or voids in the metal. By locking in the temperature at 850 degrees Celsius, the system promotes the formation of a dense, non-porous layer.

Understanding the Trade-offs

While precision muffle furnaces are essential for quality, they introduce specific challenges that must be managed.

Thermal Inertia vs. Responsiveness

Muffle furnaces are designed for stability, meaning they have high thermal mass.

While this prevents rapid cooling, it also means they cannot quickly adjust if the process temperature accidentally overshoots. This makes initial calibration critical.

Uniformity Limits

Even with precision control, "box" style furnaces can experience slight temperature variations near the door or walls.

If the electrolysis cell is placed too close to a heating element or a cool spot, the mass transfer rate will vary across the electrode, leading to uneven film thickness.

Making the Right Choice for Your Goal

To maximize the quality of your electrodeposited iron, align your thermal strategy with your specific production targets.

- If your primary focus is film density: Prioritize a furnace with multi-zone control to ensure the temperature is uniform across the entire length of the electrode, preventing porosity.

- If your primary focus is process consistency: Ensure your controller is calibrated strictly to 850 degrees Celsius to maintain constant viscosity and conductivity, removing variables from batch to batch.

Ultimately, the muffle furnace is not just a heat source; it is the primary regulator of the electrochemical kinetics that define the purity of your final product.

Summary Table:

| Process Parameter | Impact of Precision Temperature Control | Resulting Iron Quality |

|---|---|---|

| Electrolyte Solubility | Ensures uniform Fe2O3 dissolution | Consistent ion concentration |

| Salt Viscosity | Optimizes fluid movement & mass transfer | Smooth, continuous coating |

| Conductivity | Reduces electrical resistance | High energy efficiency |

| Nucleation Rate | Governs atomic arrangement on surface | Dense, non-porous iron film |

| Thermal Stability | Prevents ion transfer disruption | High purity & structural integrity |

Elevate Your Materials Synthesis with KINTEK Precision

Precise thermal management is the difference between porous defects and high-purity excellence. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory or industrial needs. Whether you are optimizing molten salt electrolysis or advanced chemical vapor deposition, our furnaces provide the stability your research demands.

Ready to refine your thermal process? Contact KINTEK today for a customized solution!

Visual Guide

References

- Zhongya Pang, Xingli Zou. Direct Electrodeposition of High-Purity Iron from Fe<sub>2</sub>O<sub>3</sub> in Molten Calcium Chloride. DOI: 10.2355/isijinternational.isijint-2023-462

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What other applications do muffle furnaces have? Unlock Versatile Uses in Labs and Manufacturing

- What are the key design differences between muffle furnaces and drying ovens? Choose the Right Tool for Your Lab

- What are the cost differences between industrial muffle furnaces and drying ovens? Understand the Price Gap and Choose Wisely

- How does a box furnace work? A Guide to Precise, Uniform Heat Treatment

- What are the design characteristics of muffle furnaces that contribute to their efficiency? Discover Key Features for Superior Performance

- What role does a laboratory high-temperature furnace play during the pyrolysis stage of UHTCMCs?

- What are the benefits of using a box furnace? Versatile, Uniform Heating for Your Lab

- What is the significance of a high-temperature chamber sintering furnace in alumina lattice performance? Master Densification