The primary benefits of a box furnace are its exceptional versatility, uniform heating, and operational simplicity. These furnaces are designed as reliable workhorses for a wide range of thermal processes, from laboratory testing to small-scale production, offering precise temperature control and a durable, low-maintenance design.

A box furnace is the quintessential general-purpose tool for heat treatment. Its greatest strength is its flexibility, but understanding its limitations compared to more specialized furnaces—like tube or vacuum models—is critical for selecting the right equipment for your specific goal.

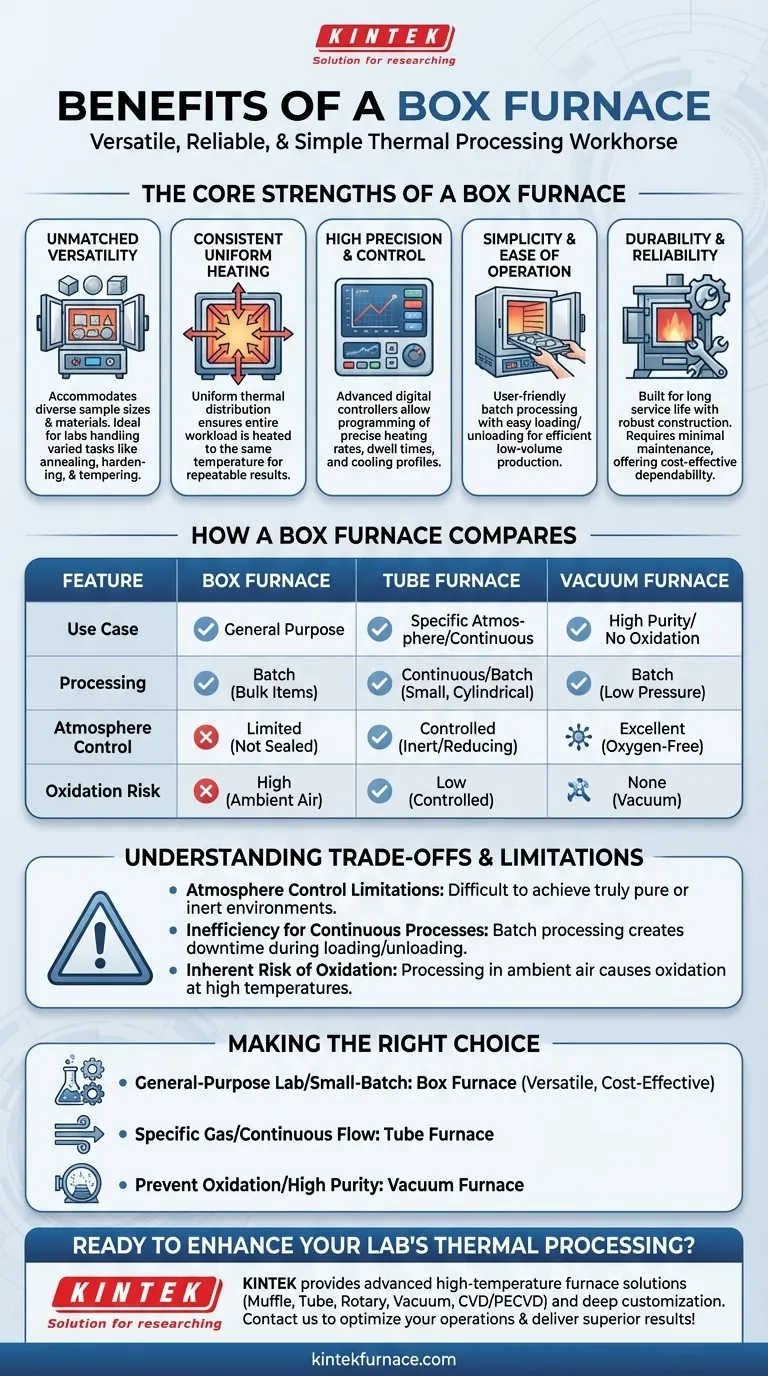

The Core Strengths of a Box Furnace

A box furnace, also known as a muffle furnace, is a type of batch furnace characterized by its rectangular or cubic chamber. Its design is fundamental to its primary advantages.

Unmatched Versatility for General Use

The simple, open chamber of a box furnace can accommodate a wide variety of sample sizes, shapes, and materials. This makes it an ideal choice for laboratories and workshops that handle diverse and unpredictable tasks.

It is suitable for numerous processes, including annealing, hardening, tempering, and materials testing, without requiring specialized setups for each one.

Consistent and Uniform Heating

Heating elements are typically arranged to provide uniform thermal distribution throughout the entire chamber. This ensures that the entire workpiece or batch of materials is heated to the same temperature, leading to consistent and repeatable results.

High Precision and Control

Modern box furnaces are equipped with advanced digital controllers that allow for highly precise temperature management. Operators can program specific heating rates, dwell times, and cooling profiles to meet the exact requirements of a heat treatment process.

Simplicity and Ease of Operation

The design prioritizes user-friendliness. Materials are easily loaded and unloaded through a large, front-facing door, making batch processing straightforward and efficient for low-volume production.

Durability and Reliability

These furnaces are generally built for a long service life with robust construction. Their relatively simple design requires minimal maintenance, making them a cost-effective and dependable asset over the long term.

How a Box Furnace Compares to Other Furnace Types

Understanding the "why" behind choosing a box furnace requires comparing it to more specialized alternatives. Its general-purpose nature is its strength, but specific applications may demand a different tool.

Box Furnace vs. Tube Furnace

A tube furnace is designed for processing materials within a narrow tube, often under a tightly controlled atmosphere or in a continuous flow.

While a box furnace heats bulkier items in a batch, a tube furnace excels at uniform heating for smaller, cylindrical samples and processes requiring specific gas environments (e.g., inert or reducing atmospheres).

Box Furnace vs. Vacuum Furnace

A vacuum furnace operates at very low pressure, creating a processing environment free from oxygen and other reactive gases.

This is its critical advantage: it prevents oxidation and contamination. A box furnace processes materials in ambient air, making it unsuitable for reactive metals or applications demanding the highest material purity. The vacuum furnace is the specialized solution for this challenge.

Understanding the "Batch" Category

A box furnace is a type of batch furnace. This means it processes materials in discrete lots. This offers flexibility for custom jobs and low-volume work but is less efficient for high-volume, continuous manufacturing.

Understanding the Trade-offs and Limitations

No single tool is perfect for every job. The strengths of a box furnace come with inherent trade-offs.

Atmosphere Control Limitations

While some box furnaces can be modified for a controlled atmosphere by introducing a gas, they are not sealed as effectively as a purpose-built tube or vacuum furnace. Achieving a truly pure or inert environment is difficult.

Inefficiency for Continuous Processes

The batch-by-batch nature of a box furnace creates downtime during loading and unloading. For high-volume production, a conveyor or continuous tube furnace is far more efficient.

Inherent Risk of Oxidation

Processing materials in an air atmosphere means oxidation is a certainty for susceptible materials at high temperatures. If your material is sensitive to oxygen, a box furnace is not the right choice without significant modifications.

Making the Right Choice for Your Application

Selecting the correct furnace is a crucial decision that directly impacts the quality of your results. Base your choice on the primary requirement of your process.

- If your primary focus is general-purpose lab work or varied, small-batch production: A box furnace is the ideal, versatile, and cost-effective choice.

- If your primary focus is processing with a specific gas atmosphere or in a continuous flow: A tube furnace is better suited for your needs.

- If your primary focus is preventing any oxidation or contamination for high-purity results: A vacuum furnace is the necessary tool for the job.

Choosing the right furnace begins with a clear understanding of your material, your process, and your desired outcome.

Summary Table:

| Benefit | Description |

|---|---|

| Versatility | Suitable for diverse materials and processes like annealing and hardening. |

| Uniform Heating | Ensures consistent temperature distribution for repeatable results. |

| Precision Control | Advanced digital controllers for exact temperature management. |

| Ease of Operation | Simple batch processing with easy loading and unloading. |

| Durability | Robust, low-maintenance design for long-term reliability. |

Ready to enhance your lab's thermal processing? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our box furnaces and other solutions can optimize your operations and deliver superior results!

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the function of a high-temperature muffle furnace in ZnO-SP preparation? Master Nanoscale Synthesis Control

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- How does a high-temperature muffle furnace contribute to the thermal treatment process of chalcopyrite ore?

- How is the thermal stability of KBaBi compounds evaluated? Discover Precise XRD & Heat Treatment Limits

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?