At its core, a muffle furnace's efficiency stems from a combination of superior thermal insulation, precise temperature control, and the isolation of the internal chamber from both contaminants and the heating elements themselves. These design characteristics work together to minimize heat loss, reduce energy consumption, and ensure the process being performed is both repeatable and reliable.

A muffle furnace is engineered not just for heat, but for control. Its efficiency is a direct result of design choices that prioritize retaining thermal energy, distributing it uniformly, and protecting the sample, which ultimately saves time, reduces operational costs, and guarantees consistent outcomes.

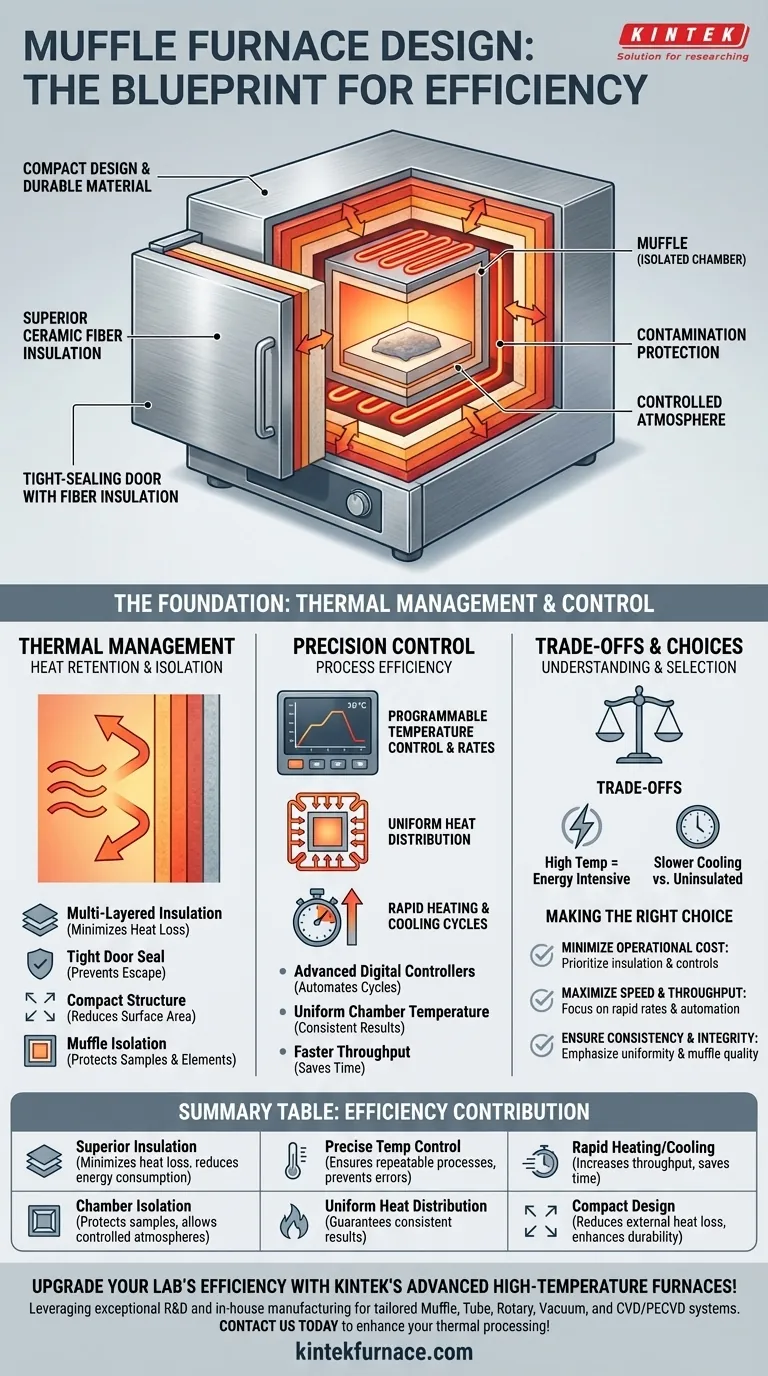

The Foundation of Efficiency: Thermal Management

The primary goal of a muffle furnace's physical design is to generate and contain extreme heat with minimal waste. Every component is selected to support this objective.

Superior Insulation and Heat Retention

A furnace's ability to hold its temperature is the single most important factor in its energy efficiency. This is achieved through multi-layered insulation.

Modern furnaces use thick walls of high-grade ceramic fiber materials. These materials have very low thermal conductivity, acting like a sophisticated thermos to keep heat inside the chamber instead of letting it escape into the lab.

The furnace door, a common point of heat loss, receives special attention. It is typically packed with the same high-performance fiber insulation to ensure a tight seal and maintain thermal integrity.

Compact Design and Material Choice

The external housing, often made of textured stainless steel, provides durability and resistance to the high-temperature environment. The compact overall design minimizes the external surface area, further reducing potential heat loss.

This sturdy, heat-resistant construction ensures the furnace's longevity and reliability, making it a cost-effective instrument over its long operational life.

Isolation of the Heating Chamber (The "Muffle")

The defining feature of this furnace is the muffle—an inner chamber that separates the material being processed from the heating elements.

This isolation is critical for two reasons. First, it protects sensitive materials from contamination by the heating elements. Second, it creates a clean, controlled environment where a specific protective atmosphere can be introduced if needed, which is essential for many metallurgical processes.

Precision Control for Process Efficiency

Beyond simply retaining heat, a furnace's efficiency is measured by its ability to deliver that heat precisely where and when it is needed. This is the role of the control system.

Programmable Temperature Control

Modern muffle furnaces feature advanced digital controllers. These allow an operator to program not just a target temperature but also the specific heating and cooling rates.

This level of control is crucial for processes that require stepped temperature changes. Automating these cycles eliminates manual oversight, ensures perfect repeatability, and reduces the chance of user error, thereby preventing wasted time and materials.

Uniform Heat Distribution

Efficiency is lost if one part of the chamber is hotter than another, leading to inconsistent results. Muffle furnaces are designed for high temperature uniformity.

Heating elements are strategically placed around the muffle to ensure the entire chamber volume reaches and maintains the set temperature. This guarantees that every part of a sample receives the exact same thermal treatment, a cornerstone of reliable scientific and industrial work.

Rapid Heating and Cooling

While robust insulation is key for holding heat, modern designs also emphasize rapid heating and cooling cycles. This is an efficiency of time.

Faster cycles increase throughput, allowing more samples to be processed in a given workday. This is particularly valuable in high-demand environments like quality control labs or for specific analyses such as thermogravimetric analysis (TGA).

Understanding the Trade-offs

No design is without its compromises. Understanding these limitations is key to using a muffle furnace effectively.

Energy Consumption at High Temperatures

Despite their efficient design, reaching very high temperatures (up to 1800°C) is an energy-intensive process. The efficiency lies in how well the furnace maintains that temperature, not in making the initial heating effortless.

The Cost of Precision

The high-quality, heat-resistant materials, premium components, and sophisticated programmable controllers that make these furnaces efficient also contribute to a higher initial purchase price compared to simpler ovens.

Slower Cooling vs. Uninsulated Ovens

The excellent insulation that holds heat so effectively can also mean that a muffle furnace cools down more slowly than a less-insulated oven. While modern models have improved this, it remains a factor for processes requiring rapid quenching without specialized equipment.

Making the Right Choice for Your Goal

To select or operate a muffle furnace effectively, align its features with your primary definition of efficiency.

- If your primary focus is minimizing operational cost: Prioritize models with the highest quality insulation, a tight-sealing door, and modern, energy-efficient digital controls.

- If your primary focus is process speed and throughput: Look for furnaces that advertise rapid heating rates and have fully programmable controls to automate cycles.

- If your primary focus is result consistency and sample integrity: The most important features are exceptional temperature uniformity and the quality of the muffle's isolation.

By understanding these core design principles, you can confidently select the right instrument to achieve precise, repeatable, and efficient thermal processing.

Summary Table:

| Design Characteristic | Contribution to Efficiency |

|---|---|

| Superior Insulation | Minimizes heat loss, reduces energy consumption |

| Precise Temperature Control | Ensures repeatable processes, prevents errors |

| Chamber Isolation | Protects samples from contamination, allows controlled atmospheres |

| Uniform Heat Distribution | Guarantees consistent results across samples |

| Rapid Heating/Cooling | Increases throughput, saves time |

| Compact Design | Reduces external heat loss, enhances durability |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs for optimal performance and cost savings. Contact us today to discuss how our furnaces can enhance your thermal processing!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis