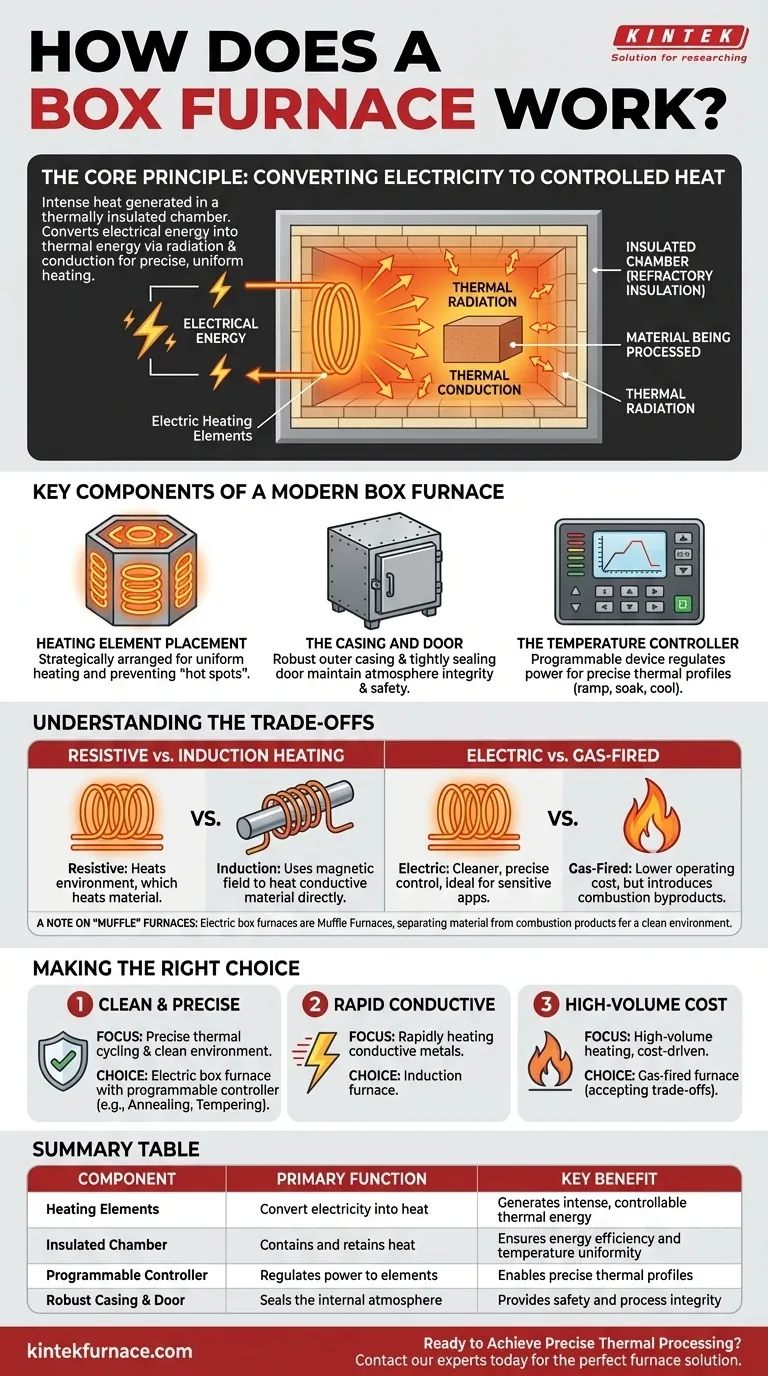

At its core, a box furnace works by using electric heating elements to generate intense heat inside a thermally insulated chamber. This process converts electrical energy into thermal energy, heating the materials placed inside through a combination of radiation and conduction to achieve precise, controlled temperatures.

The defining principle of a box furnace is not just generating heat, but creating a highly uniform and controllable thermal environment. It achieves this by using resistive heating within a sealed, insulated box, making it a versatile and reliable tool for a wide range of material processing applications.

The Core Principle: Converting Electricity to Controlled Heat

The fundamental operation of a box furnace is elegant in its simplicity. It's a system designed to contain and control thermal energy with high precision.

The Role of Heating Elements

The process begins with the heating elements. These are typically made of a material with high electrical resistance. When a strong electric current is passed through them, they glow hot, converting electrical energy directly into heat energy.

The Insulated Chamber

This heat is generated within a chamber lined with high-performance refractory insulation, such as ceramic bricks or fiberboard. This insulated box is the furnace's defining feature, designed to minimize heat loss and ensure energy efficiency.

How Heat Reaches the Material

The intense heat from the elements travels to the material inside the chamber through two primary mechanisms.

- Thermal Radiation: The hot elements and internal walls of the furnace radiate thermal energy in all directions, which is absorbed by the surface of the material being processed.

- Thermal Conduction: Heat is also conducted through the atmosphere within the furnace (be it air or a specific gas) to the material.

Key Components of a Modern Box Furnace

While the principle is straightforward, a modern box furnace's effectiveness comes from the synergy of its key components.

Heating Element Placement

To ensure uniform heating, the elements are strategically arranged on multiple sides of the chamber—often the sides, top, and bottom. This multi-directional heating prevents "hot spots" and ensures the entire workpiece reaches the target temperature evenly.

The Casing and Door

The system is enclosed in a robust outer casing with a tightly sealing door. This maintains the integrity of the internal atmosphere and provides a crucial safety barrier.

The Temperature Controller

Perhaps the most critical component for modern applications is the programmable temperature controller. This microprocessor-based device regulates the power sent to the heating elements, allowing users to execute precise thermal profiles, including specific ramp rates, soak times at a set temperature, and controlled cooling.

Understanding the Trade-offs

A box furnace excels at specific tasks, but it's important to understand how it differs from other heating technologies.

Resistive vs. Induction Heating

A box furnace uses resistive heating, where the environment is heated, which in turn heats the material. This is different from an induction furnace, which uses a magnetic field to generate eddy currents directly within a conductive material, causing it to heat from the inside out. Induction is often faster but is limited to conductive materials.

Electric vs. Fuel-Fired

While most modern box furnaces are electric, gas-fired options exist.

- Electric furnaces offer a cleaner heating environment and far more precise temperature control, making them ideal for sensitive applications.

- Gas-fired furnaces may offer lower operating costs but introduce combustion byproducts into the chamber, which can be unsuitable for processes requiring high purity.

A Note on "Muffle" Furnaces

An electric box furnace is a type of muffle furnace. The term "muffle" refers to a design where the material being heated is separated from the direct products of combustion. Because electric elements produce no combustion, the environment is inherently clean and separate from the energy source.

Making the Right Choice for Your Application

Selecting the right heating technology depends entirely on your primary objective.

- If your primary focus is precise thermal cycling and a clean environment: An electric box furnace with a programmable controller is the definitive choice for applications like annealing, tempering, and ceramic firing.

- If your primary focus is heating conductive metals as rapidly as possible: An induction furnace is likely a more efficient solution for your specific needs.

- If your primary focus is high-volume heating where operating cost is the main driver: A gas-fired furnace may be a consideration, but you must accept the trade-off of a less controlled and less pure atmosphere.

Ultimately, the box furnace stands as a reliable and highly versatile workhorse for achieving precise and uniform heat treatment.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Heating Elements | Convert electricity into heat | Generates intense, controllable thermal energy |

| Insulated Chamber | Contains and retains heat | Ensures energy efficiency and temperature uniformity |

| Programmable Controller | Regulates power to elements | Enables precise thermal profiles (ramp, soak, cool) |

| Robust Casing & Door | Seals the internal atmosphere | Provides safety and process integrity |

Ready to Achieve Precise Thermal Processing?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our box furnaces are engineered for superior temperature uniformity and control, ideal for annealing, tempering, ceramic firing, and other critical heat treatment applications.

Our value to you:

- Precision & Control: Execute complex thermal profiles with accuracy for reliable, repeatable results.

- Durability & Efficiency: Built with high-performance insulation and robust components for long-term, energy-efficient operation.

- Deep Customization: We tailor our solutions—including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—to meet your unique experimental requirements.

Let's discuss your specific needs. Contact our experts today to find the perfect furnace solution for your lab.

Visual Guide

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does high-temperature heating facilitate the conversion of rice husks into inorganic precursors for silica extraction?

- What is the core function of a muffle furnace in biomass activation? Optimize Carbonization & Pore Development

- What is the function of a high-temperature muffle furnace in HZSM-5 preparation? Master Catalytic Activation

- Why is a high-temperature muffle furnace used for Ni-BN powder preheating? Achieve defect-free coating density.

- What is the critical role of a high-temperature muffle furnace in converting biomass into Fe-N-BC?