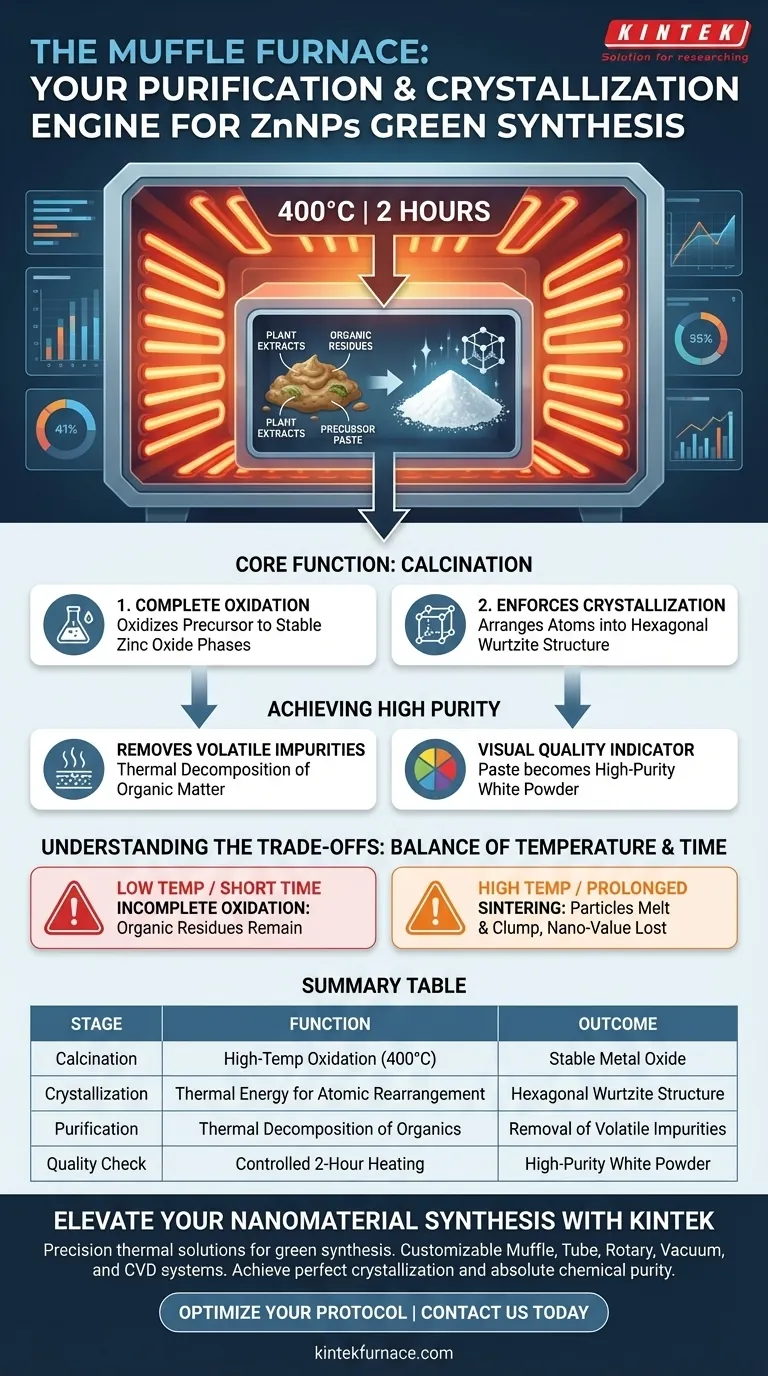

The muffle furnace acts as the definitive purification and crystallization engine in the green synthesis of zinc oxide nanoparticles (ZnNPs). Its primary function is to perform calcination, subjecting the synthesized precursor paste to a sustained temperature of approximately 400°C for two hours. This intense thermal treatment is the specific mechanism that converts the intermediate biological paste into a high-purity, white zinc oxide powder.

Core Takeaway In green synthesis, the initial reaction creates a "dirty" precursor laden with organic residues. The muffle furnace solves this by utilizing high-temperature oxidation to simultaneously burn off volatile impurities and force the zinc and oxygen atoms into a stable, crystalline lattice structure.

The Physiology of Calcination

Driving Complete Oxidation

The synthesis process prior to the furnace yields a precursor paste, not the final oxide. The muffle furnace provides a stable, oxygen-rich environment required to chemically alter this precursor.

By maintaining a temperature of 400°C, the furnace ensures the complete oxidation of the zinc species. This transforms the intermediate compounds into stable metal oxide phases, which is the chemical definition of the final product.

Enforcing Crystallization

Heat is the energy source required for atomic rearrangement. The thermal energy provided by the furnace allows atoms to move and lock into a highly ordered structure.

This process, known as crystallization, ensures the ZnNPs do not remain amorphous (shapeless). Instead, the controlled heat drives the atoms to arrange themselves into a specific crystal lattice, often the hexagonal wurtzite structure. This structural integrity is vital for the material's physical and chemical stability.

Achieving High Purity

Removing Volatile Impurities

Green synthesis relies on biological agents (such as plant extracts) to reduce metal salts. Consequently, the precursor paste is initially contaminated with residual organic matter and biological compounds.

The muffle furnace eliminates these contaminants through thermal decomposition. The high heat effectively vaporizes volatile biological impurities, leaving behind only the inorganic zinc oxide.

The Visual Indicator of Quality

The effectiveness of this purification is visibly apparent in the final product.

Before calcination, the paste may be discolored due to organic residues. After the 2-hour treatment at 400°C, the result is a high-purity white powder. This color change is a primary indicator that the organic matter has been successfully removed and the synthesis is complete.

Understanding the Trade-offs

The Balance of Temperature and Time

While the muffle furnace is a tool of precision, incorrect settings can degrade the nanomaterial.

If the temperature is too low or the duration too short, oxidation will be incomplete, leaving organic impurities that compromise the material's properties.

Conversely, excessive heat or prolonged exposure can lead to sintering. This occurs when individual nanoparticles melt together to form larger clumps, effectively destroying the "nano" characteristics that give the material its unique value.

Making the Right Choice for Your Goal

To maximize the efficacy of the muffle furnace in your synthesis protocol, consider your specific end-goals:

- If your primary focus is Chemical Purity: Ensure the furnace maintains a consistent oxidative atmosphere to fully decompose the specific biological agents used in your green synthesis paste.

- If your primary focus is Structural Integrity: Adhere strictly to the 400°C limit; this provides enough energy for atomic rearrangement into a crystalline phase without inducing aggressive particle agglomeration.

Ultimately, the muffle furnace transforms a chaotic biological mixture into a refined, engineered nanomaterial.

Summary Table:

| Stage of Synthesis | Function of Muffle Furnace | Outcome of Process |

|---|---|---|

| Calcination | High-temperature oxidation (400°C) | Converts precursor paste into stable metal oxide |

| Crystallization | Thermal energy for atomic rearrangement | Formation of hexagonal wurtzite crystal structure |

| Purification | Thermal decomposition of organic matter | Removal of volatile biological impurities |

| Quality Check | Controlled 2-hour heating cycle | Visual transition to high-purity white powder |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is non-negotiable when converting biological precursors into high-value nanoparticles. KINTEK provides industry-leading thermal solutions designed for the rigors of green synthesis and material science.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific temperature and atmospheric requirements. Whether you are aiming for perfect crystallization or absolute chemical purity, our lab high-temp furnaces ensure consistent results every time.

Ready to optimize your calcination protocol? Contact us today to find the perfect furnace for your lab.

Visual Guide

References

- Khyati Saini, Naveen Singhal. GREEN SYNTHESIZED ZNO NANOPARTICLES WITH CORDYCEPS MILITARIS FUNGUS EXTRACT FOR THE TREATMENT OF MEMORY IMPAIRMENT IN ALZHIEMER DISEASE. DOI: 10.22159/ijap.2025v17i1.53491

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a laboratory muffle furnace play in analyzing organic matter degradation? Optimize Biomass Pretreatment

- What is the typical function of a laboratory muffle furnace in the preparation of chemical catalysts? | KINTEK

- How do the chamber sizes of muffle furnaces and drying ovens compare? Key Differences Explained

- How are muffle furnaces used in jewelry making? Achieve Precision in Metal Clay and Annealing

- Why use a high-temp box resistance furnace for Ca2.5Ag0.3Sm0.2Co4O9 sintering? Ensure Phase Purity and Alignment

- Why are high-precision box experimental furnaces necessary for FeCrAl overlay research? Master Thermal Aging Precision

- What is the primary principle of a muffle furnace? Achieve Clean, Contamination-Free Heating for Your Materials

- Why is an industrial-grade burnout furnace required for enameled copper wire scrap? Ensure High Purity Copper Refining