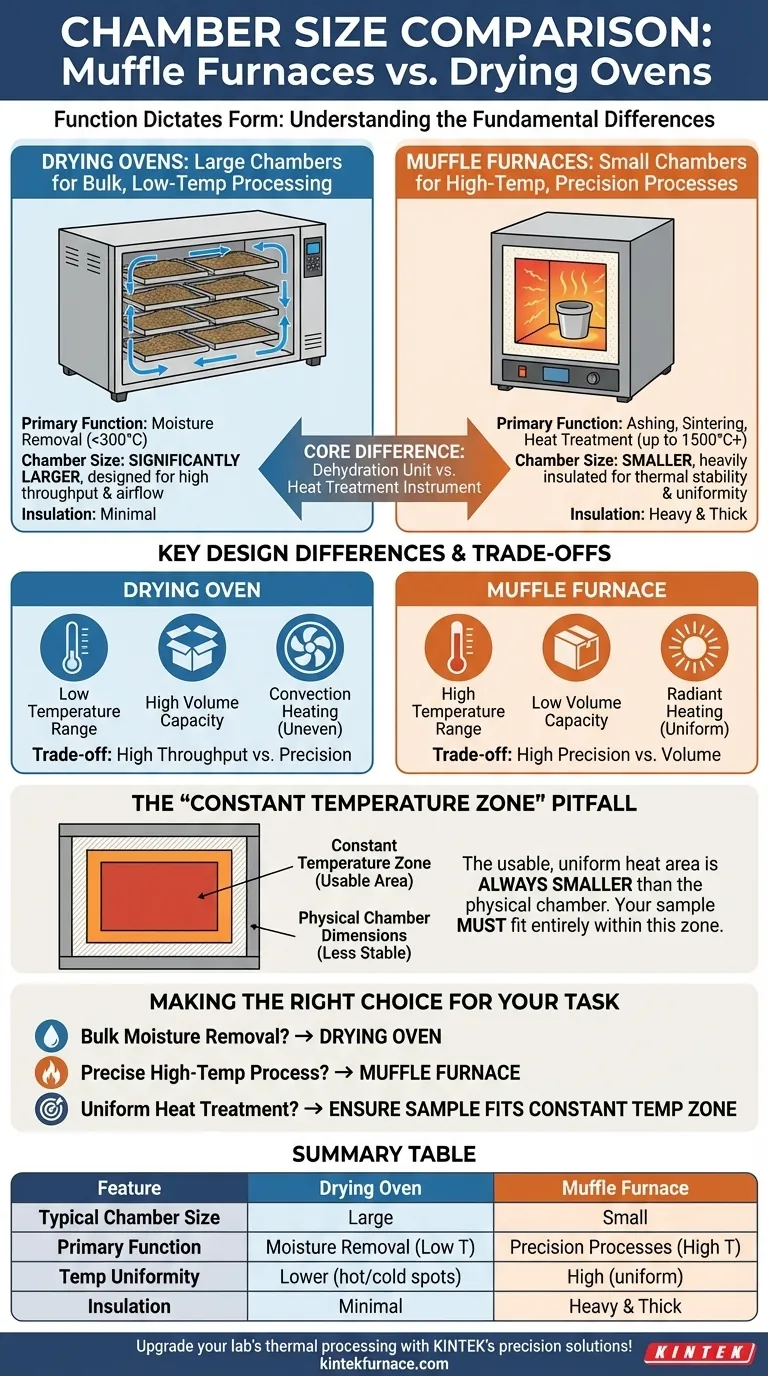

In short, drying ovens typically have significantly larger chambers than muffle furnaces. This difference in size is not arbitrary; it is a direct consequence of their fundamentally different purposes, temperature ranges, and internal construction. While both are thermal processing tools, they are engineered to solve entirely distinct problems.

The core principle to understand is that chamber size is dictated by function. Drying ovens are built for high-volume, low-temperature moisture removal, necessitating large chambers. Muffle furnaces are designed for low-volume, high-temperature, precision processes, which require smaller, heavily insulated, and tightly controlled chambers.

The Core Difference: Function Dictates Form

The most important distinction to grasp is that you are not comparing two similar tools. You are comparing a high-capacity dehydration unit to a high-precision heat treatment instrument.

Drying Ovens: Bulk Processing and Moisture Removal

A drying oven's primary job is to remove moisture from materials at relatively low temperatures, typically up to around 300°C.

To do this effectively for bulk samples, it needs a large chamber to maximize throughput.

Its design prioritizes airflow, circulating fresh air over heating elements and exhausting the resulting moist air to facilitate drying.

Muffle Furnaces: High-Temperature, Precision Processing

A muffle furnace is engineered for processes like ashing, sintering, or heat-treating materials that require extremely high and uniform temperatures, often up to 1500°C or more.

This mission requires a smaller, more controlled chamber. The smaller volume allows for more rapid and uniform heating.

These chambers are sealed during operation and do not rely on airflow. Instead, heat is distributed evenly within a static, heavily insulated environment.

Key Design Differences Driven by Temperature

The vast difference in operating temperature is the main driver behind every other design choice, including chamber size and construction.

Insulation and Heat Containment

Muffle furnaces feature heavy, thick insulation to safely contain extreme temperatures and maintain thermal stability. This extensive insulation inherently limits the practical size of the internal chamber.

Drying ovens, operating at much lower temperatures, have minimal insulation. This allows for larger chamber construction without the prohibitive weight, cost, and footprint of a heavily insulated unit.

Temperature Uniformity and Control

Muffle furnaces are designed to create an exceptionally uniform temperature distribution. Heat radiates from elements surrounding the chamber, ensuring the sample is heated evenly from all sides.

Drying ovens, which rely on convection (moving hot air), often suffer from uneven heat distribution, resulting in hot and cold spots within their larger chambers.

Understanding the Critical Trade-offs

Choosing between these tools involves trade-offs between volume, temperature, and precision. Misunderstanding these can lead to failed processes and damaged equipment.

Throughput vs. Precision

A drying oven offers high throughput for low-temperature tasks. You can process large batches of material at once.

A muffle furnace offers high precision for high-temperature tasks. The trade-off for this control and temperature capability is a much smaller processing volume.

The "Constant Temperature Zone" Pitfall

A common mistake is assuming the entire chamber volume provides uniform heat. This is never the case.

Every furnace and oven has a "constant temperature zone," which is the usable area where the temperature is stable and uniform. This zone is always smaller than the physical chamber dimensions.

For a process to be successful, your sample must fit entirely within this constant temperature zone, not just inside the chamber.

Making the Right Choice for Your Task

Your decision should be based entirely on the requirements of your specific thermal process.

- If your primary focus is removing moisture from bulk materials at low temperatures: A drying oven is the correct choice due to its large capacity and airflow design.

- If your primary focus is precise, high-temperature processes like ashing, annealing, or material testing: A muffle furnace is non-negotiable for its temperature accuracy, uniformity, and range.

- If your primary focus is achieving uniform heat treatment for any sample: You must select a unit where the specified "constant temperature zone" is larger than your sample.

Ultimately, you must select the instrument that is purpose-built for your specific temperature and precision requirements.

Summary Table:

| Feature | Drying Oven | Muffle Furnace |

|---|---|---|

| Typical Chamber Size | Large | Small |

| Primary Function | Moisture removal at low temperatures (up to ~300°C) | High-temperature precision processes (up to 1500°C+) |

| Temperature Uniformity | Lower, with hot/cold spots | High, with uniform distribution |

| Insulation | Minimal | Heavy and thick |

| Ideal Use Cases | Bulk drying, dehydration | Ashing, sintering, heat treatment |

Upgrade your lab's thermal processing with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance your efficiency and accuracy!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites