The defining principle of a muffle furnace is the complete isolation of the material being heated from the byproducts of combustion or the direct heating source itself. This is accomplished by enclosing the sample within a separate, insulated chamber—the "muffle." This design ensures the sample is exposed only to controlled, uniform heat, preventing any contamination that would occur in a direct-fired furnace.

The core challenge in many high-temperature applications is achieving extreme heat without corrupting the sample. A muffle furnace solves this by functioning as a high-temperature oven where the heating elements are outside the chamber, transferring heat indirectly and guaranteeing a pristine environment for the material inside.

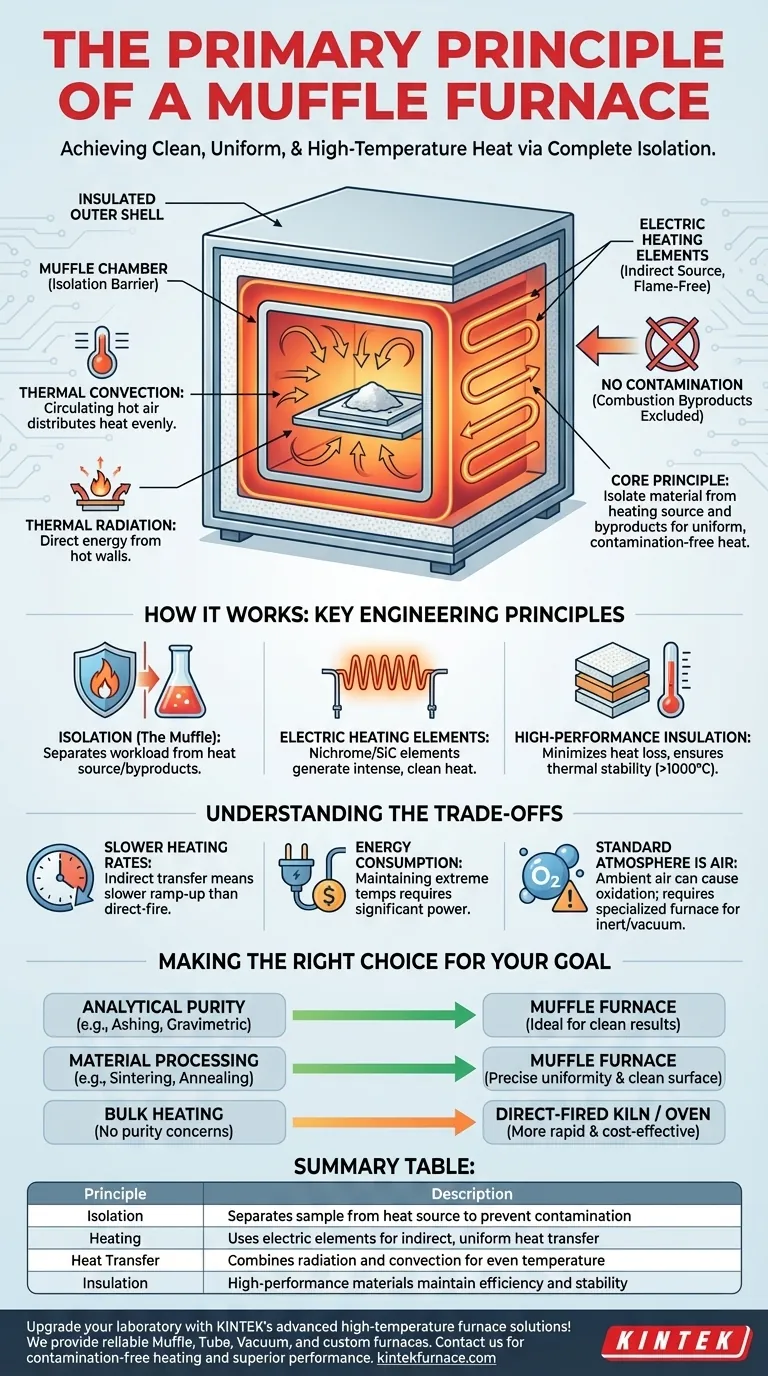

How a Muffle Furnace Achieves Clean, Uniform Heat

The operation of a muffle furnace relies on a few key engineering principles working in concert to create a highly controlled environment.

The Principle of Isolation

The name "muffle" refers to the core concept of muffling or separating the workload from the heat source. In older designs, this meant keeping burning fuel and exhaust gases away from the sample.

In modern electric furnaces, it means the heating elements do not come into direct contact with the sample, preventing any potential contamination from the elements themselves.

The Role of Electric Heating Elements

Contemporary muffle furnaces are almost exclusively electric. They use high-resistance wires or rods, often made of materials like nichrome or silicon carbide, which line the walls of the heating chamber.

When a strong electrical current passes through these elements, they glow red-hot, generating intense heat without producing any flame, smoke, or chemical byproducts.

Heat Transfer Through Radiation and Convection

The heat generated by the elements is transferred into the sample chamber through two primary mechanisms:

- Thermal Radiation: The hot inner walls of the furnace radiate thermal energy directly to the surface of the material being heated, much like the heat you feel from the sun.

- Thermal Convection: The air inside the chamber heats up, becomes less dense, and circulates. This movement of hot air helps distribute the temperature evenly throughout the chamber, ensuring the entire sample reaches a uniform temperature.

The Importance of High-Performance Insulation

To reach and maintain temperatures often exceeding 1000°C (1800°F), the chamber is encased in layers of high-performance ceramic insulation.

This insulation is critical for minimizing heat loss to the surrounding environment. This not only improves energy efficiency but is essential for achieving the thermal stability and temperature uniformity required for sensitive scientific and industrial processes.

Understanding the Trade-offs

While indispensable for many tasks, the muffle furnace's design comes with inherent trade-offs that are important to recognize.

Slower Heating Rates

Because the heat is transferred indirectly, muffle furnaces can have slower ramp-up times compared to direct-fire kilns where a flame directly impinges on the material.

Energy Consumption

Maintaining a highly insulated box at extreme temperatures requires a significant and continuous input of electrical energy, which can be a primary operational cost.

Standard Atmosphere is Air

A standard muffle furnace heats a sample in a clean environment, but that environment is still ambient air. This can lead to oxidation at high temperatures. If a process requires an inert atmosphere (like argon or nitrogen) or a vacuum, a specialized furnace is necessary.

Making the Right Choice for Your Goal

Your specific application dictates whether the unique benefits of a muffle furnace are the right fit for your work.

- If your primary focus is analytical purity: Use a muffle furnace for tasks like ashing materials, gravimetric analysis, or trace metal determination, where any external contamination would invalidate the results.

- If your primary focus is material processing: The furnace is ideal for sintering, annealing, or heat-treating metals and ceramics where precise temperature uniformity and a clean surface finish are critical.

- If your primary focus is simply bulk heating without purity concerns: A direct-fired kiln or a standard industrial oven may be a more rapid and cost-effective solution for your needs.

Ultimately, the muffle furnace is the definitive tool when a pristine, uniformly heated environment is non-negotiable.

Summary Table:

| Principle | Description |

|---|---|

| Isolation | Separates sample from heat source to prevent contamination |

| Heating | Uses electric elements for indirect, uniform heat transfer |

| Heat Transfer | Combines radiation and convection for even temperature |

| Insulation | High-performance materials maintain efficiency and stability |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, delivering contamination-free heating, energy efficiency, and superior performance. Contact us today to discuss how we can enhance your processes and achieve your goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure