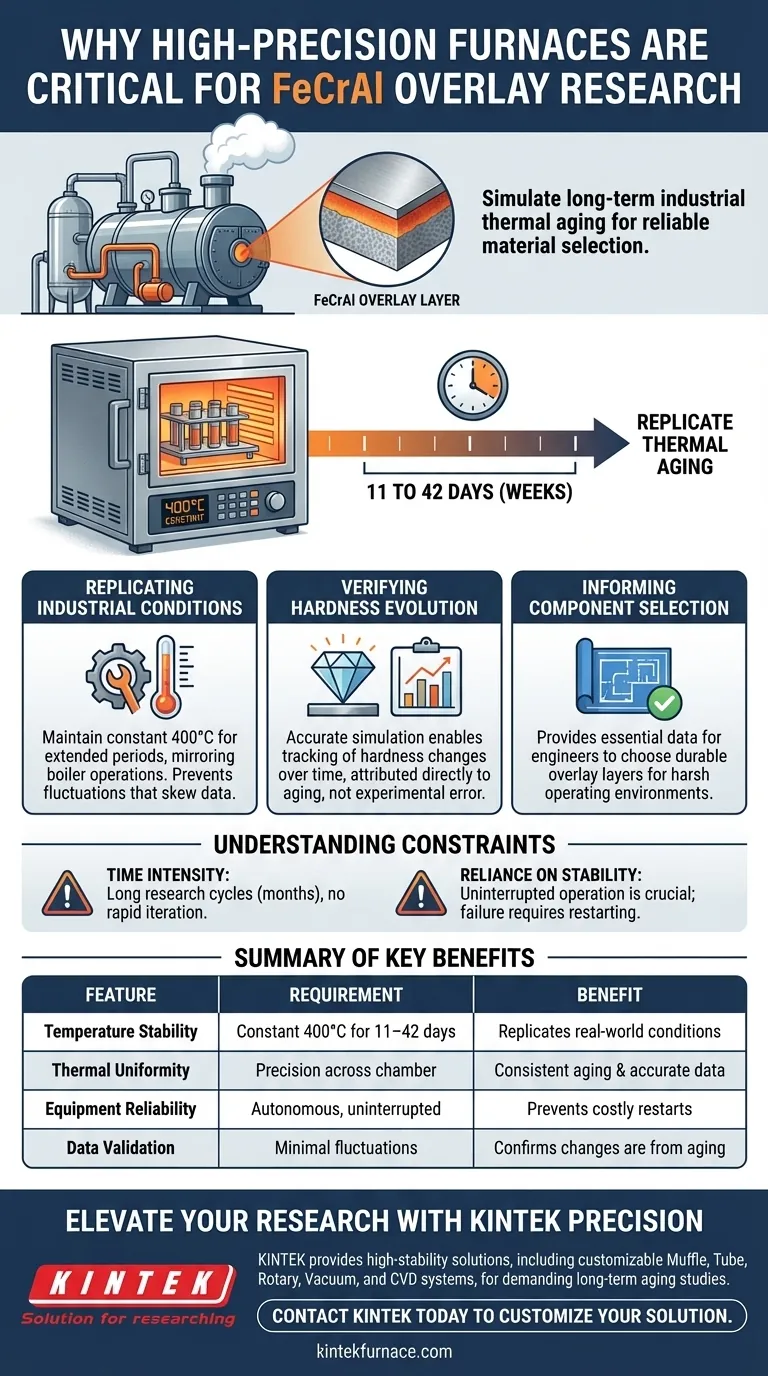

High-precision box experimental furnaces are critical for research on FeCrAl overlay layers because they provide the strictly controlled environment necessary to simulate long-term industrial thermal aging. Specifically, these furnaces are required to maintain a constant temperature, such as 400 degrees Celsius, for extended periods ranging from 11 to 42 days, ensuring accurate verification of hardness evolution trends.

Reliable material selection for industrial boiler components depends on understanding how materials degrade over time. High-precision furnaces enable researchers to replicate these harsh conditions over weeks, providing the essential data needed to predict material performance.

Simulating Industrial Conditions

To understand how FeCrAl overlay layers will perform in the real world, researchers must move beyond short-term testing. They need to replicate the sustained thermal stress found in industrial environments.

The Necessity of Long-Term Stability

Industrial boiler components function continuously for long durations. To simulate this, experimental setups must run for weeks rather than hours.

According to the primary reference, specific testing protocols require maintaining conditions for 11 to 42 days. Only a high-precision furnace can ensure the temperature remains constant throughout this extended timeframe without fluctuations that would skew the data.

Replicating Thermal Aging

Materials behave differently when exposed to heat for long periods, a process known as thermal aging.

To observe the true effects of aging on FeCrAl layers, the environment must be held at a steady 400 degrees Celsius. High-precision box furnaces provide the thermal uniformity required to ensure that the aging process observed in the lab mirrors reality.

Analyzing Material Performance

The ultimate goal of using high-precision equipment is to derive actionable data regarding the material's physical properties.

Verifying Hardness Evolution

A key performance metric for FeCrAl overlay layers is how their hardness evolves under thermal stress.

Fluctuations in temperature can produce inconsistent hardness readings. By ensuring a stable thermal environment, researchers can attribute changes in hardness directly to the material's aging process rather than experimental error.

Informing Component Selection

The data derived from these rigorous tests is not merely academic.

It provides the essential data needed to select the appropriate materials for industrial boiler components. Engineers rely on this verified hardness data to choose overlay layers that will withstand actual operating conditions.

Understanding the Constraints

While high-precision box furnaces are necessary for accurate simulation, researchers must be aware of the inherent challenges in this testing methodology.

The Trade-off of Time Intensity

The primary constraint of this approach is the significant time investment.

Because the simulation requires 11 to 42 days of continuous operation, rapid iteration is impossible. Research cycles are long, meaning that a failure in equipment or setup on day 30 requires restarting a month-long process.

Reliance on Environmental Stability

The validity of the data is entirely dependent on the uninterrupted stability of the furnace.

If the equipment loses precision or experiences power interruptions during the multi-week cycle, the simulation of "constant temperature" is compromised. This necessitates robust equipment that can operate autonomously and reliably for weeks at a time.

Making the Right Choice for Your Goal

To ensure your research into FeCrAl overlay layers yields valid industrial data, align your testing protocols with your specific objectives.

- If your primary focus is verifying material durability: Prioritize equipment capable of maintaining strict thermal stability over cycles lasting at least 42 days to accurately map hardness evolution.

- If your primary focus is industrial application: Use the data derived from these long-term aging simulations to validate material selection for boiler components operating at 400 degrees Celsius.

By investing in high-precision thermal control, you transform raw experimental data into reliable engineering solutions.

Summary Table:

| Feature | Requirement for FeCrAl Research | Benefit to Material Analysis |

|---|---|---|

| Temperature Stability | Constant 400°C for 11–42 days | Replicates real-world industrial boiler conditions |

| Thermal Uniformity | Precision across the entire chamber | Ensures consistent aging and accurate hardness data |

| Equipment Reliability | Autonomous, uninterrupted operation | Prevents costly restarts in month-long research cycles |

| Data Validation | Minimal fluctuations | Confirms changes are due to aging, not experimental error |

Elevate Your Material Research with KINTEK Precision

Precise data is the foundation of reliable industrial engineering. KINTEK provides the high-stability thermal solutions necessary for demanding long-term aging studies. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temperature furnaces—all fully customizable to meet the rigorous constraints of your FeCrAl overlay research.

Don't let equipment fluctuations compromise weeks of data. Ensure your material performance predictions are accurate with KINTEK’s industry-leading thermal control.

Contact KINTEK today to customize your high-precision furnace solution.

Visual Guide

References

- María Asunción Valiente Bermejo, Mattias Thuvander. Microstructure and Properties of FeCrAl Overlay Welds at High Temperature Service. DOI: 10.1007/s11661-025-07846-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What industrial applications do muffle furnaces have in heat treating? Precision Solutions for High-Tech Industries

- What is the role of a laboratory box muffle furnace in the compositional analysis of finger millet popcorn?

- How does a high-precision muffle furnace contribute to the evaluation of coatings? 1100°C Oxidation Test Insights

- What applications do box type resistance furnaces have in ceramics and glass processing? Essential for Sintering and Hot Bending

- How does a forced convection oven facilitate the curing of flame-retardant epoxy resin? Ensure Uniform Cross-Linking

- What role does a high-temperature muffle furnace play in KNN-based ceramic powder pre-sintering? Key Synthesis Insights

- What role does a laboratory high-temperature furnace play during the pyrolysis stage of UHTCMCs?

- How should samples be placed inside the muffle furnace? Ensure Uniform Heating and Safety