Proper sample placement in a muffle furnace is critical for achieving accurate results and preventing damage to the equipment. Samples should always be placed neatly in the center of the furnace chamber, ensuring they do not touch the interior walls, heating elements, or the delicate thermocouple sensor.

The goal of sample placement is not just about location, but about creating an environment for uniform heating, equipment protection, and operator safety. Mastering the entire process, including the cool-down, is essential for reliable and safe operation.

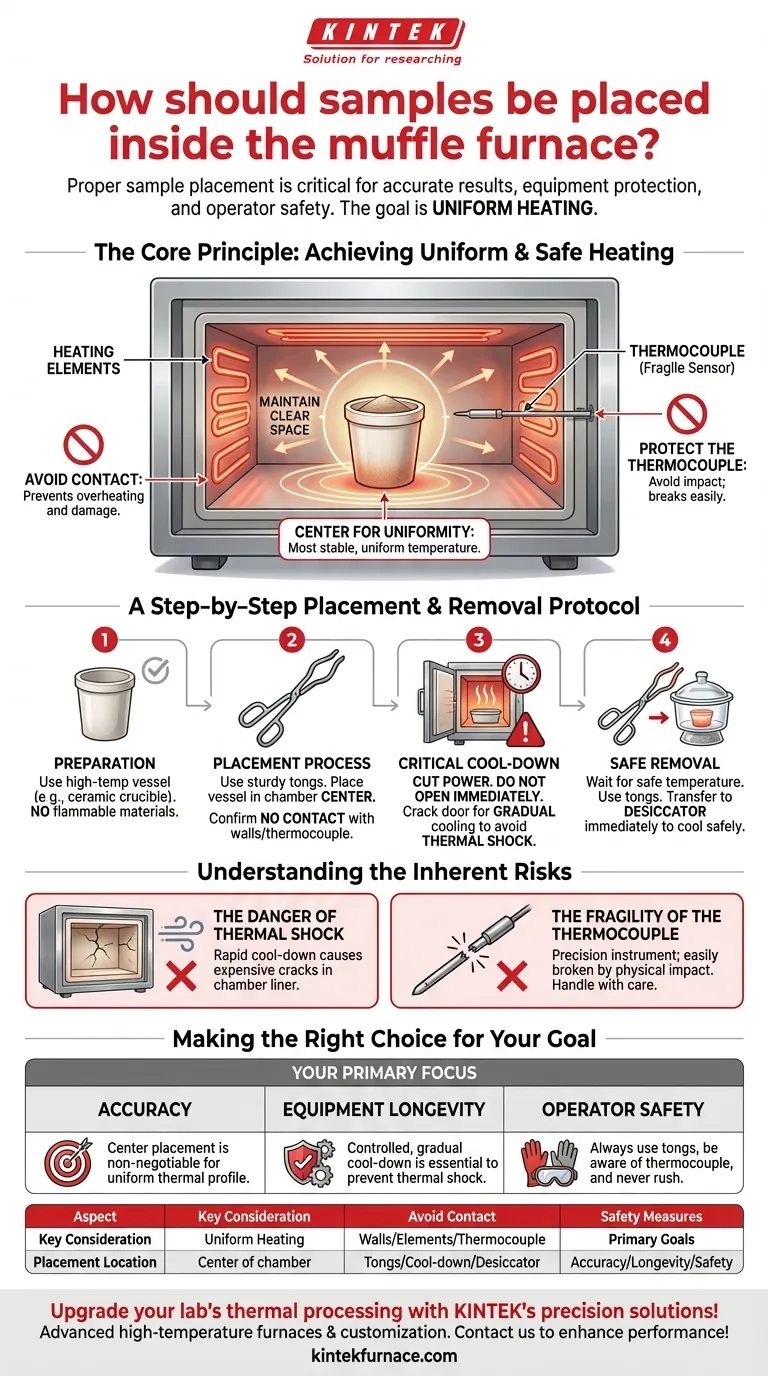

The Core Principle: Achieving Uniform and Safe Heating

The correct placement of your sample is foundational to any successful thermal process. The primary objectives are to ensure the sample is heated evenly and to protect the furnace's critical components from damage.

Center for Uniformity

The geometric center of the furnace chamber is the area with the most stable and uniform temperature. Placing samples here ensures that the entire sample mass experiences the same thermal profile, which is crucial for processes like ashing, annealing, or chemical analysis where consistency is key.

Avoid Contact with Heating Elements

The furnace walls contain the heating elements. Direct contact between your crucible or sample and these elements can cause localized overheating, potentially damaging both the sample and the element itself. Maintaining a clear space around the sample ensures it is heated by radiant and convective heat, not direct conduction.

Protect the Thermocouple

The thermocouple is a temperature sensor that extends into the furnace chamber. It is extremely fragile, especially at high temperatures. Accidentally bumping or touching it with a crucible can easily break its junction, rendering the furnace's temperature control system inoperative and requiring repair.

A Step-by-Step Placement and Removal Protocol

Following a strict protocol from start to finish minimizes risk and ensures repeatable results.

Preparation Before Heating

Ensure your sample is contained in a suitable, high-temperature-rated vessel, such as a ceramic crucible. Verify that no flammable, volatile, or explosive materials are being placed in the furnace or stored nearby.

The Placement Process

Open the furnace door and, using a pair of long, sturdy crucible tongs, carefully place the sample vessel in the center of the furnace floor. Visually confirm that it is not touching the walls or the thermocouple before closing the door securely.

The Critical Cool-Down Phase

After the heating cycle is complete, cut the power supply. Do not open the furnace door immediately. A rapid influx of cool air will create thermal shock, which can cause the ceramic furnace chamber to crack.

Instead, open the door just a small crack. This allows heat to dissipate gradually. Wait until the internal temperature has dropped significantly before proceeding.

Safe Sample Removal

Once the furnace has cooled to a safe temperature, you may fully open the door. Use crucible tongs to carefully remove the hot vessel. To prevent burns and protect the sample from atmospheric moisture as it cools, immediately transfer the hot crucible to a desiccator.

Understanding the Inherent Risks

Muffle furnaces are powerful tools, and improper use carries significant risks for both the equipment and the operator.

The Danger of Thermal Shock

Rushing the cool-down process is the most common cause of furnace damage. The expansion and contraction of the ceramic liner must be managed carefully. A cracked chamber is an expensive and time-consuming repair that renders the furnace unusable.

The Fragility of the Thermocouple

A broken thermocouple is the second most common point of failure. It is a precision instrument that cannot withstand physical impact. Always be deliberate and cautious when placing or removing items to protect this vital sensor.

Making the Right Choice for Your Goal

Your primary objective should guide your focus during the procedure.

- If your primary focus is result accuracy: Center placement is non-negotiable for ensuring your sample experiences a perfectly uniform thermal profile.

- If your primary focus is equipment longevity: The controlled, gradual cool-down procedure is the single most important step to prevent cracking the furnace chamber from thermal shock.

- If your primary focus is operator safety: Always use appropriate tongs, be acutely aware of the thermocouple's location, and never rush any part of the heating or cooling process.

By treating the muffle furnace with methodical care, you ensure the integrity of your results, the longevity of the equipment, and the safety of your lab.

Summary Table:

| Aspect | Key Consideration |

|---|---|

| Placement Location | Center of furnace chamber for uniform heating |

| Avoid Contact | Keep samples away from walls, heating elements, and thermocouple |

| Safety Measures | Use crucible tongs, controlled cool-down, and desiccator for removal |

| Primary Goals | Accuracy, equipment longevity, and operator safety |

Upgrade your lab's thermal processing with KINTEK's precision solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures they meet your unique experimental needs for accurate, safe, and efficient results. Contact us today to discuss how our products can enhance your laboratory's performance and reliability!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity