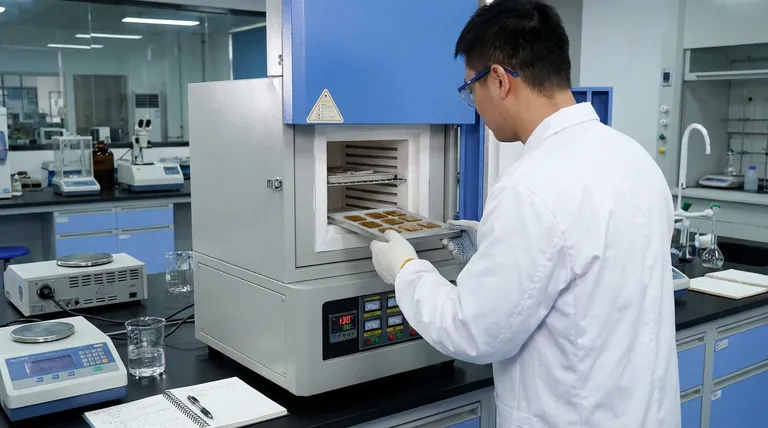

A forced convection oven facilitates the curing of flame-retardant epoxy resin mixtures by utilizing active air circulation to create a highly uniform thermal environment. This mechanism allows for precise, stepped temperature profiles—specifically regimes such as 130°C followed by 150°C—which are necessary to activate the chemical reaction between DGBEA, flame retardants, and curing agents. By maintaining consistent airflow, the oven ensures that heat is distributed evenly, preventing the uneven curing that often occurs in static heating environments.

The core advantage of forced convection is its ability to minimize the temperature gradient between a material's surface and its core. This thermal uniformity is the deciding factor in achieving full cross-linking and high-performance structural integrity in thick epoxy samples.

The Mechanics of Uniform Curing

Eliminating Thermal Gradients in Thick Samples

In static ovens, heat often penetrates a material from the outside in, causing the surface to cure faster than the center.

Forced convection ovens solve this by circulating hot air, which minimizes the temperature difference (gradient) between the interior and exterior of the sample.

This is particularly critical for thick samples, ensuring the material reaches thermal equilibrium quickly and cures consistently throughout its volume.

Driving the Chemical Reaction

The curing process relies on a specific chemical reaction between epoxy groups and amine curing agents.

This reaction requires sustained, even heat to facilitate full cross-linking of the molecular chains.

Without the uniform heat provided by forced convection, the cross-linking may be incomplete, leading to weak spots or compromised flame-retardant properties.

The Importance of Process Control

Executing Stepped Temperature Profiles

Curing complex mixtures containing DGBEA (Diglycidyl ether of bisphenol A) often requires a multi-stage heating process.

The primary reference highlights a specific requirement for a stepped environment, utilizing distinct phases at 130°C and 150°C.

Forced convection allows for rapid and precise adjustments to these temperature setpoints, ensuring the material spends the exact required time at each thermal stage.

Common Pitfalls to Avoid

The Risk of Static Heating

Attempting to cure these specific mixtures without forced air circulation often leads to thermal stratification.

In a static environment, hot air rises and stagnates, creating "hot spots" and "cold spots" within the chamber.

This lack of uniformity prevents the precise 130°C/150°C stepping required, resulting in a product where the outer shell is over-cured while the inner core remains under-cured.

Making the Right Choice for Your Goal

To achieve the high-performance structure described in the reference, consider the following when setting up your curing process:

- If your primary focus is structural integrity: Ensure your oven creates enough airflow to penetrate thick samples, guaranteeing full cross-linking from core to surface.

- If your primary focus is process consistency: Program your oven to strictly follow the stepped temperature profile (e.g., 130°C to 150°C) to accommodate the specific chemistry of DGBEA and amine agents.

Uniform thermal management is the key to transforming a raw resin mixture into a durable, fully cured flame-retardant material.

Summary Table:

| Feature | Forced Convection Benefit | Impact on Epoxy Curing |

|---|---|---|

| Airflow | Active circulation & distribution | Prevents hot/cold spots & thermal stratification |

| Temperature Gradient | Minimizes core-to-surface delta | Ensures consistent cross-linking in thick samples |

| Process Control | Rapid, precise stepped profiles | Accurate execution of 130°C/150°C curing stages |

| Material Integrity | Uniform thermal equilibrium | Maximizes structural strength & flame retardancy |

Elevate Your Material Performance with KINTEK

Precision is non-negotiable when curing high-performance flame-retardant resins. KINTEK provides industry-leading forced convection ovens and high-temperature lab furnaces designed to eliminate thermal gradients and ensure perfect cross-linking every time.

Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique laboratory needs.

Ready to achieve superior structural integrity? Contact us today to consult with our experts and find the ideal thermal solution for your research and production.

References

- Younghun Kim, Gyojic Shin. Influence of Thiol-Functionalized Polysilsesquioxane/Phosphorus Flame-Retardant Blends on the Flammability and Thermal, Mechanical, and Volatile Organic Compound (VOC) Emission Properties of Epoxy Resins. DOI: 10.3390/polym16060842

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the thermochemical conversion research of animal-derived waste? Optimize Pyrolysis

- What makes muffle furnaces versatile in their applications? Unlock Precision Heating for Diverse Industries

- What electrical safety precautions should be taken with a muffle furnace? Essential Steps to Prevent Electric Shock and Fires

- What are the common uses of a muffle furnace in material testing? Essential for Precise Thermal Analysis and Sample Prep

- What is a digital muffle furnace and why is it important? Unlock Precision Heating for Your Lab

- What maintenance practices are recommended for muffle furnaces? Ensure Longevity and Precision in Your Lab

- What role does a high-temperature muffle furnace play in g-C3N4 catalyst synthesis? Precision Pyrolysis Solutions

- What functions do drying ovens and sintering furnaces serve in Sol-Gel? Optimize Bioactive Coating Integrity