At its core, a muffle furnace's versatility comes from one key design feature: the "muffle." This is a sealed inner chamber that isolates the material being heated from the heating elements and the external atmosphere. This separation allows for precise control over both temperature and atmospheric conditions, free from contamination.

The furnace's defining feature is not just high heat, but isolated high heat. This ability to create a pure, controlled heating environment is what unlocks its use across a vast range of scientific, industrial, and artistic applications.

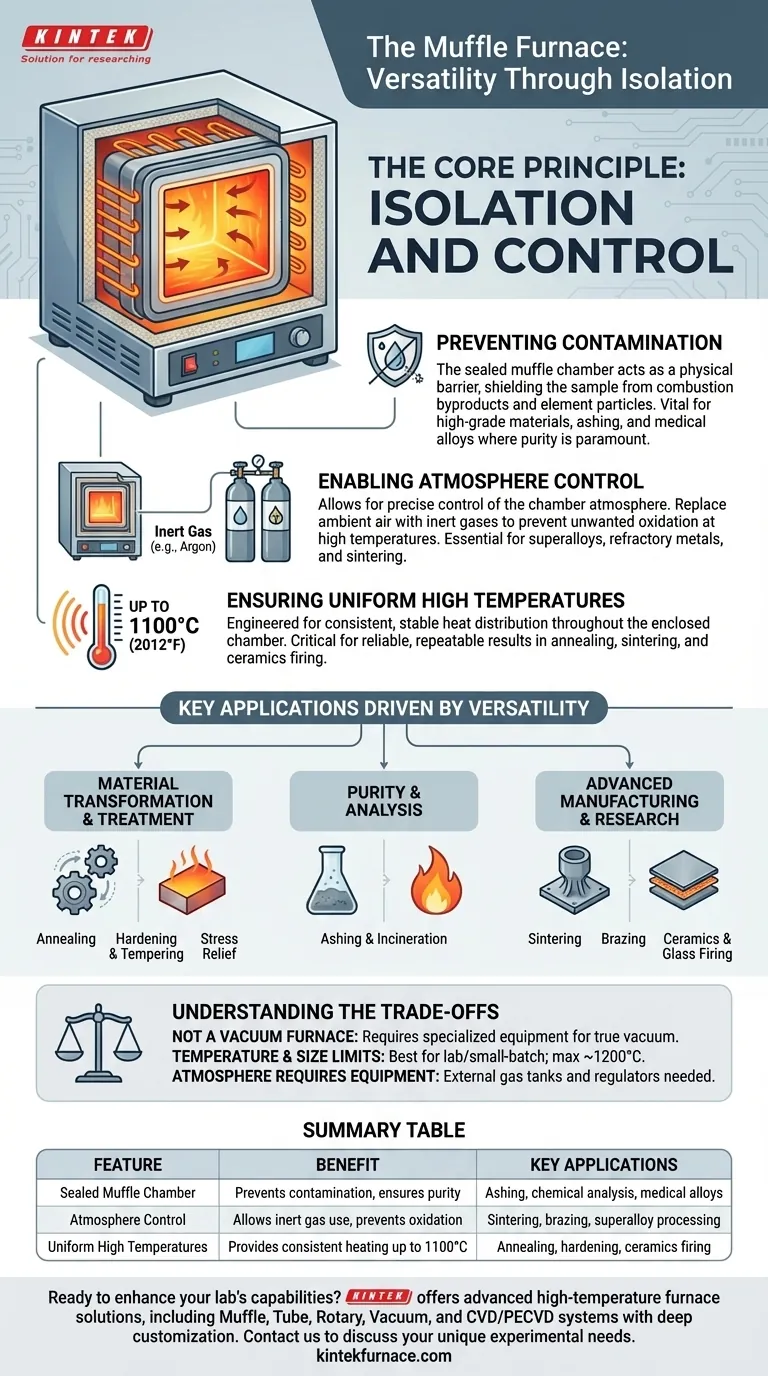

The Core Principle: Isolation and Control

The term "muffle" refers to the protective barrier at the heart of the furnace. Understanding how this simple concept works reveals why the furnace is such a powerful and adaptable tool.

Preventing Contamination

The muffle chamber acts as a physical shield. It prevents byproducts from fuel combustion or microscopic particles from the electric heating elements from coming into contact with the sample.

This is critical for processes where purity is paramount, such as producing high-grade materials, ashing samples for chemical analysis, or creating medical-grade alloys.

Enabling Atmosphere Control

Because the sample is in a sealed chamber, you can control the gas inside it. You can heat the material in ambient air or purge the air and replace it with an inert gas like argon or nitrogen.

This prevents oxidation—an unwanted chemical reaction with oxygen that can ruin sensitive materials at high temperatures. This capability is essential for working with superalloys, refractory metals, and certain ceramics.

Ensuring Uniform High Temperatures

Muffle furnaces are engineered to provide consistent, stable heat, often reaching temperatures up to 1100°C (2012°F).

The enclosed design helps distribute this heat evenly throughout the chamber, ensuring the entire sample is processed under the same conditions. This uniformity is vital for reliable and repeatable results in processes like annealing and sintering.

Key Applications Driven by Versatility

This combination of isolation, atmosphere control, and uniform heat makes the muffle furnace indispensable for a wide variety of tasks.

Material Transformation and Treatment

Many applications involve changing the physical properties of a material. A muffle furnace provides the necessary controlled environment for processes like:

- Annealing: Softening metals to make them more workable.

- Hardening & Tempering: Strengthening metals through controlled heating and cooling cycles.

- Stress Relief: Removing internal stresses from a material caused by manufacturing.

Purity and Analysis

In analytical chemistry and materials science, the goal is often to break down a sample to study its components.

- Ashing & Incineration: Burning off all organic matter from a sample to leave behind only the inorganic residue for analysis. The muffle ensures a clean, complete burn without introducing contaminants.

Advanced Manufacturing and Research

Modern manufacturing relies on precise thermal processing, which muffle furnaces provide.

- Sintering: Fusing powdered materials (like ceramics or metals in 3D printing) into a solid mass just below their melting point.

- Brazing: Joining two pieces of metal using a filler metal.

- Ceramics & Glass Firing: Providing the precise, high-temperature firing schedules needed to create durable ceramic and glass pieces.

Understanding the Trade-offs

While highly versatile, a muffle furnace is not the universal solution for every heating application. Understanding its limitations is key to using it effectively.

Not a Vacuum Furnace

A standard muffle furnace is designed for atmospheric pressure or inert gas environments. Achieving a true vacuum requires a specialized and more expensive vacuum furnace, which is a different class of equipment.

Temperature and Size Limits

Most common muffle furnaces operate up to around 1100-1200°C. Processes requiring significantly higher temperatures will demand furnaces with different heating elements and insulation. Furthermore, their size is often best suited for laboratory, prototyping, or small-batch production rather than large-scale industrial runs.

Atmosphere Requires Additional Equipment

While capable of housing an inert atmosphere, this functionality requires external gas tanks, regulators, and plumbing. Simply using the furnace in ambient air is far simpler than setting up and managing a controlled gas environment.

Making the Right Choice for Your Goal

To determine if a muffle furnace fits your needs, consider your primary objective.

- If your primary focus is Purity and Analysis (e.g., ashing): The key benefit is the contamination-free environment that ensures accurate analytical results.

- If your primary focus is Metal Treatment (e.g., annealing): The combination of uniform heat and the option for atmosphere control to prevent surface scaling is what you need.

- If your primary focus is Advanced Materials (e.g., sintering 3D parts): The ability to use an inert atmosphere at high temperatures to prevent oxidation is the critical feature.

Ultimately, the muffle furnace is a cornerstone of thermal processing because its design fundamentally separates the heat source from the material, giving you control.

Summary Table:

| Feature | Benefit | Key Applications |

|---|---|---|

| Sealed Muffle Chamber | Prevents contamination, ensures purity | Ashing, chemical analysis, medical alloys |

| Atmosphere Control | Allows inert gas use, prevents oxidation | Sintering, brazing, superalloy processing |

| Uniform High Temperatures | Provides consistent heating up to 1100°C | Annealing, hardening, ceramics firing |

Ready to enhance your lab's capabilities with a tailored muffle furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're in materials science, chemistry, or manufacturing, our furnaces deliver precise temperature control, contamination-free environments, and reliable performance. Contact us today to discuss how we can support your specific applications and drive your research forward!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis