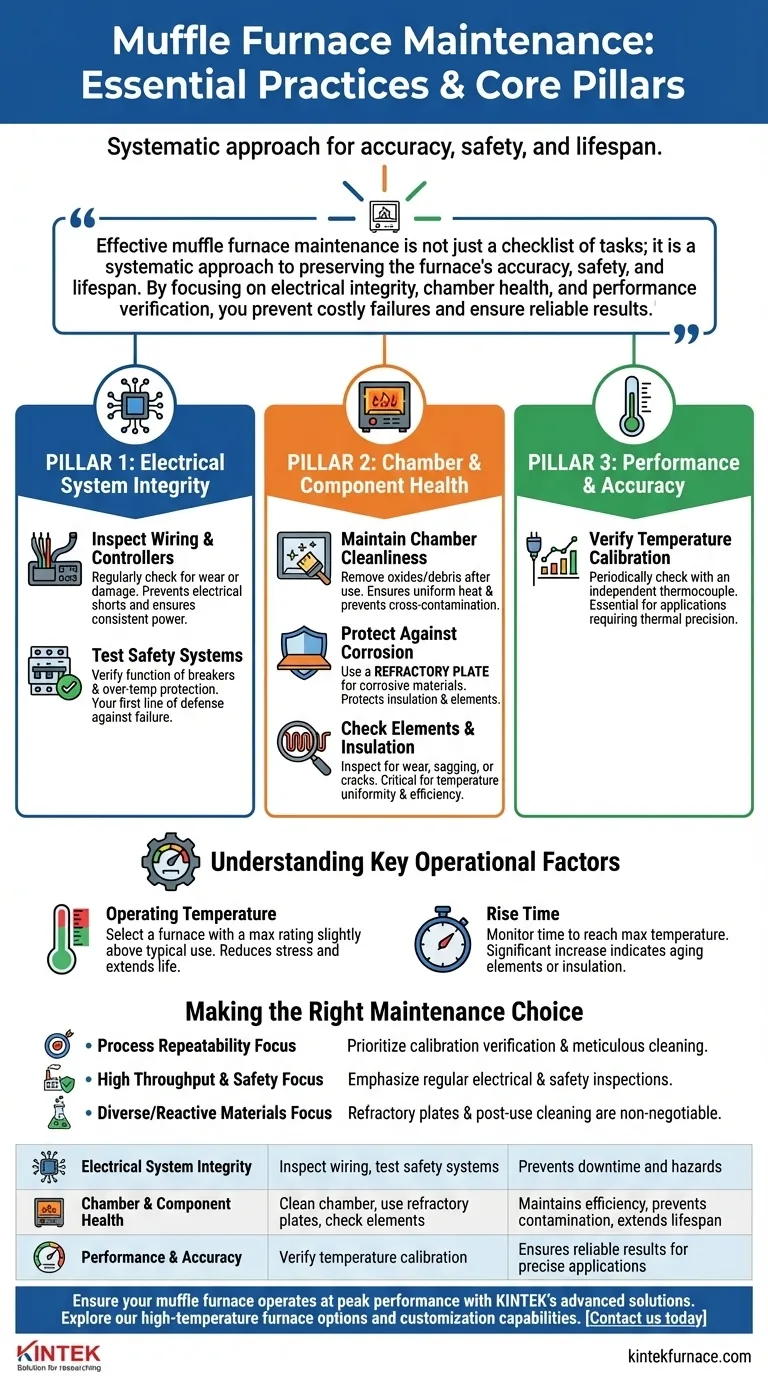

The most recommended maintenance practices for muffle furnaces focus on three core areas: electrical system integrity, chamber cleanliness and preservation, and performance accuracy. Key actions include regularly inspecting wiring and heating elements, removing all oxides and debris from the chamber, and periodically verifying temperature calibration to ensure consistent and safe operation.

Effective muffle furnace maintenance is not just a checklist of tasks; it is a systematic approach to preserving the furnace's accuracy, safety, and lifespan. By focusing on electrical integrity, chamber health, and performance verification, you prevent costly failures and ensure reliable results.

The Core Pillars of Furnace Maintenance

Proper maintenance ensures your muffle furnace remains a reliable and precise instrument. It revolves around systematically checking its key systems to prevent degradation and failure.

Pillar 1: Electrical System Integrity

Electrical faults are a primary cause of furnace downtime and a significant safety hazard.

Inspect Wiring and Controllers Regularly check all wiring for signs of wear, brittleness, or damage, particularly at connection points to the furnace and controller. This prevents electrical shorts and ensures consistent power delivery.

Test Safety Systems Periodically verify that safety features like circuit breakers and over-temperature protection systems are functioning correctly. These are your first line of defense against catastrophic failure.

Pillar 2: Chamber and Component Health

The furnace chamber is the heart of the operation, and its condition directly impacts heating efficiency and sample purity.

Maintain Chamber Cleanliness Promptly remove all oxides, residues, and debris from the furnace chamber after each use. A clean chamber ensures uniform heat radiation and prevents cross-contamination of samples.

Protect Against Corrosion For samples that may release corrosive vapors or materials, always place a refractory plate on the furnace floor. This sacrificial layer protects the underlying insulation and heating elements from chemical attack.

Check Heating Elements and Insulation Visually inspect the heating elements for signs of wear, sagging, or discoloration. Also, check the chamber's insulation for cracks or degradation, as this is critical for maintaining temperature uniformity and efficiency.

Pillar 3: Performance and Accuracy

A furnace that doesn't hold the correct temperature produces unreliable results.

Verify Temperature Calibration The accuracy of your furnace's temperature controller can drift over time. Periodically verify its calibration with an independent, calibrated thermocouple to ensure your processes are running at the specified temperature. This is essential for applications like annealing, brazing, and sintering where thermal precision is paramount.

Understanding Key Operational Factors

Beyond reactive maintenance, certain operational choices can significantly extend the life and reliability of your furnace. Proactive decisions are a form of preventative maintenance.

The Importance of Operating Temperature

Choosing the right furnace for your needs is the first step in ensuring its longevity. Continuously running a furnace at its absolute maximum temperature will accelerate wear on heating elements and insulation.

Selecting for Longevity

Select a furnace with a maximum temperature rating slightly above your typical operating temperature. This buffer allows for flexible operation without constantly stressing the components, leading to a much longer equipment life.

The Role of Rise Time

The rise time, or the time it takes to reach maximum temperature, is another indicator of furnace health. A significant increase in rise time can suggest aging heating elements or failing insulation that requires attention.

Making the Right Maintenance Choice

Your specific application determines which maintenance tasks are most critical.

- If your primary focus is process repeatability (e.g., technical ceramics, metallurgy): Prioritize routine temperature calibration verification and meticulous chamber cleaning to ensure consistent results.

- If your primary focus is high throughput and safety in a general lab: Emphasize regular inspection of electrical systems and safety cutoffs to maximize uptime and protect users.

- If your primary focus is working with diverse or potentially reactive materials: Make the use of refractory plates and post-use chamber cleaning a non-negotiable part of your standard operating procedure.

A consistent maintenance routine transforms your furnace from a simple tool into a reliable, long-term asset for your work.

Summary Table:

| Maintenance Pillar | Key Actions | Benefits |

|---|---|---|

| Electrical System Integrity | Inspect wiring, test safety systems | Prevents downtime and hazards, ensures consistent operation |

| Chamber and Component Health | Clean chamber, use refractory plates, check elements and insulation | Maintains efficiency, prevents contamination, extends lifespan |

| Performance and Accuracy | Verify temperature calibration | Ensures reliable results for precise applications |

Ensure your muffle furnace operates at peak performance with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs, enhancing safety, accuracy, and longevity. Contact us today to discuss how we can support your maintenance and operational goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency