In essence, a digital muffle furnace is a high-temperature laboratory oven that heats materials within a self-contained, insulated chamber—the "muffle." This design isolates the material from direct contact with heating elements and any contaminants from combustion. The "digital" aspect refers to its modern electronic controller, which provides exceptionally precise and programmable temperature management, ensuring process accuracy and repeatability.

The true importance of a digital muffle furnace is not just its ability to get extremely hot, but its power to create a pure, stable, and perfectly controlled thermal environment. This ensures that the only variable affecting your material is the heat itself, eliminating guesswork and contamination.

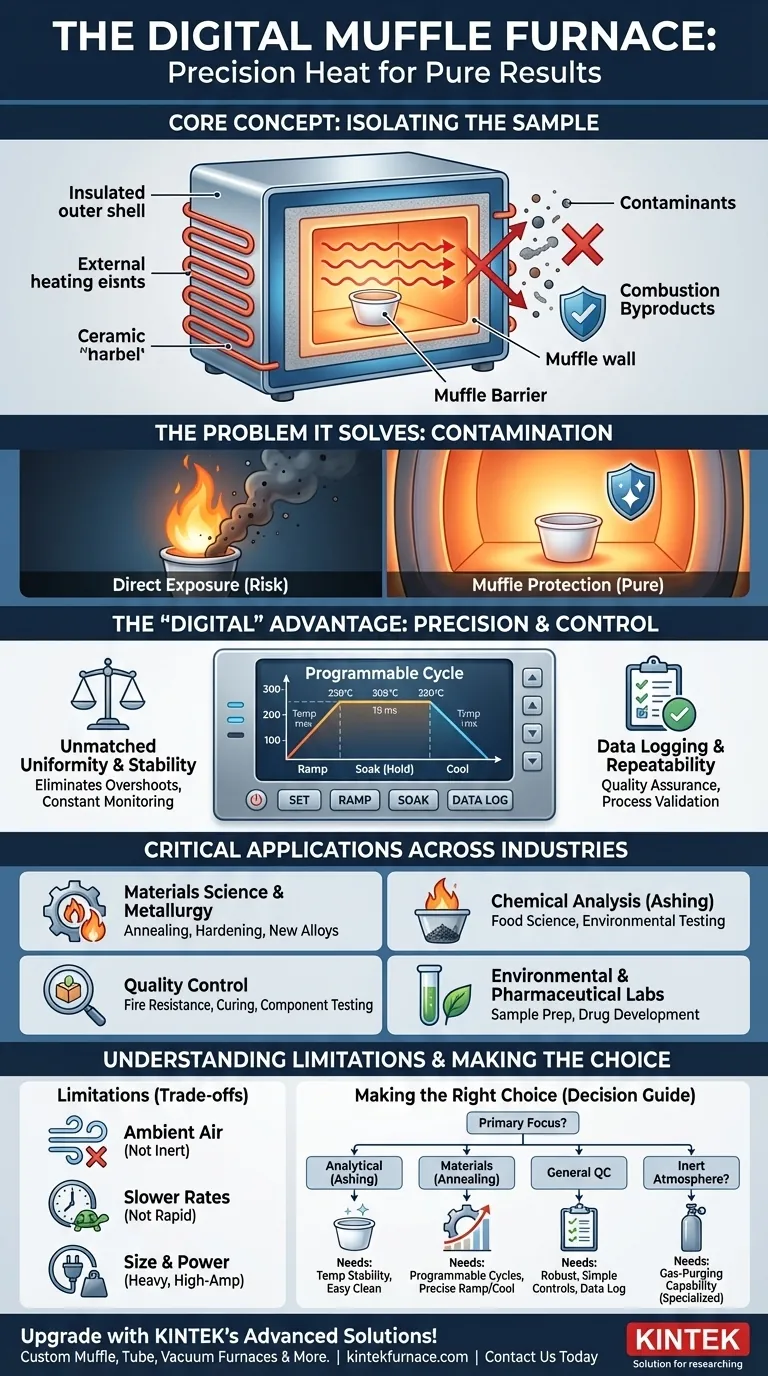

The Fundamental Principle: Isolating the Sample

A muffle furnace's design is brilliantly simple and effective. It's built around the core need to protect a sample from any external influence other than controlled, radiant heat.

What is a "Muffle"?

The "muffle" is the heart of the furnace. It's an enclosed chamber, typically made of high-temperature ceramic, that contains your sample. This chamber is placed inside a larger, insulated furnace where external heating elements heat its outer walls.

Heat then radiates from the muffle's inner walls to the sample inside. Think of it as a box-within-a-box, ensuring the sample never touches the raw heat source.

The Problem It Solves: Contamination

In many scientific and industrial processes, direct exposure to flames or electric heating elements can introduce contaminants. Byproducts of combustion or particles from the elements themselves can react with a sample, corrupting chemical analyses or altering a material's properties.

The muffle acts as a perfect barrier, guaranteeing a high-purity atmosphere where the sample's integrity is maintained.

The "Digital" Advantage: From Approximation to Precision

While older furnaces used analog dials, the shift to digital controls revolutionized what's possible. This precision is the primary reason these furnaces are indispensable in modern labs.

Programmable Temperature Cycles

Digital controllers allow you to program multi-step processes. You can define the exact rate of temperature increase (ramp), how long it holds at a peak temperature (soak), and the rate at which it cools. This is critical for complex processes like annealing metals or sintering ceramics.

Unmatched Uniformity and Stability

A digital system constantly monitors the internal temperature and makes micro-adjustments to the heating elements. This eliminates the temperature overshoots and dips common in analog systems, ensuring the temperature is uniform throughout the chamber and stable over many hours.

Data Logging and Repeatability

Many digital models can log temperature data throughout a cycle. This is vital for quality assurance, process validation in regulated industries like pharmaceuticals, and ensuring experiments can be repeated with scientific certainty.

Critical Applications Across Industries

The combination of a clean heating environment and precise control makes the digital muffle furnace a versatile workhorse in numerous fields.

Materials Science and Metallurgy

These furnaces are used for heat-treating processes like hardening, tempering, and annealing metals. They are also used to test a material's characteristics under extreme thermal stress and to develop new alloys and ceramics.

Chemical Analysis

A primary use is ashing, where a sample is burned at a high temperature to remove all organic material, leaving only the inorganic ash for analysis. This is common in food science, environmental testing, and mining to determine mineral content.

Quality Control in Manufacturing

Manufacturers use muffle furnaces to test the fire resistance of products, cure coatings and adhesives, or verify that components can withstand the temperatures they will face during operation.

Environmental and Pharmaceutical Labs

In these settings, sample purity is paramount. Muffle furnaces are used to prepare samples for analysis, such as determining pollutants in soil or water, or for pretreatment steps in drug development and testing.

Understanding the Trade-offs and Limitations

While powerful, a digital muffle furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Standard Atmosphere Control

A standard muffle furnace operates in an ambient air atmosphere. If your process requires an inert atmosphere (like nitrogen or argon) to prevent oxidation, you will need a more specialized and expensive furnace equipped with gas ports.

Heating and Cooling Rates

The heavy insulation required to reach and hold high temperatures means that muffle furnaces do not heat up or cool down instantly. Processes requiring rapid thermal cycling may need a different type of furnace.

Size and Power Requirements

These are not desktop devices. Muffle furnaces are heavy, require significant bench space, and often need dedicated high-amperage electrical circuits and proper ventilation for heat and potential fumes.

Making the Right Choice for Your Process

Your specific application will determine the most important features to look for.

- If your primary focus is analytical chemistry (ashing): You need a furnace with excellent temperature stability and a chamber that is easy to clean to prevent cross-contamination between samples.

- If your primary focus is materials heat treatment (annealing): Prioritize a furnace with highly programmable temperature cycles, including precise control over ramp and cool-down rates.

- If your primary focus is general quality control: A robust, reliable model with simple controls and data logging capabilities for process verification is your best choice.

- If you require a specific inert atmosphere: A standard muffle furnace is not sufficient; you must find a model specifically designed with gas-purging capabilities.

Ultimately, a digital muffle furnace empowers you to control heat with scientific certainty, making it an indispensable tool for achieving reliable and repeatable results.

Summary Table:

| Feature | Description |

|---|---|

| Digital Control | Programmable temperature cycles with precise ramp, soak, and cool-down rates for accuracy and repeatability. |

| Muffle Chamber | Insulated ceramic chamber isolating samples from contaminants, ensuring pure thermal environments. |

| Key Applications | Materials science (e.g., annealing), chemical analysis (e.g., ashing), quality control, and environmental/pharmaceutical labs. |

| Limitations | Operates in ambient air; not suitable for inert atmospheres without modifications; slower heating/cooling rates. |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, whether for materials science, chemical analysis, or quality control. Contact us today to discuss how our furnaces can enhance your process accuracy and efficiency!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- Why are precision stirring and drying equipment necessary for photocatalytic materials? Master Microstructure Control

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- What role does a muffle furnace play in g-C3N4 synthesis? Mastering Thermal Polycondensation for Semiconductors