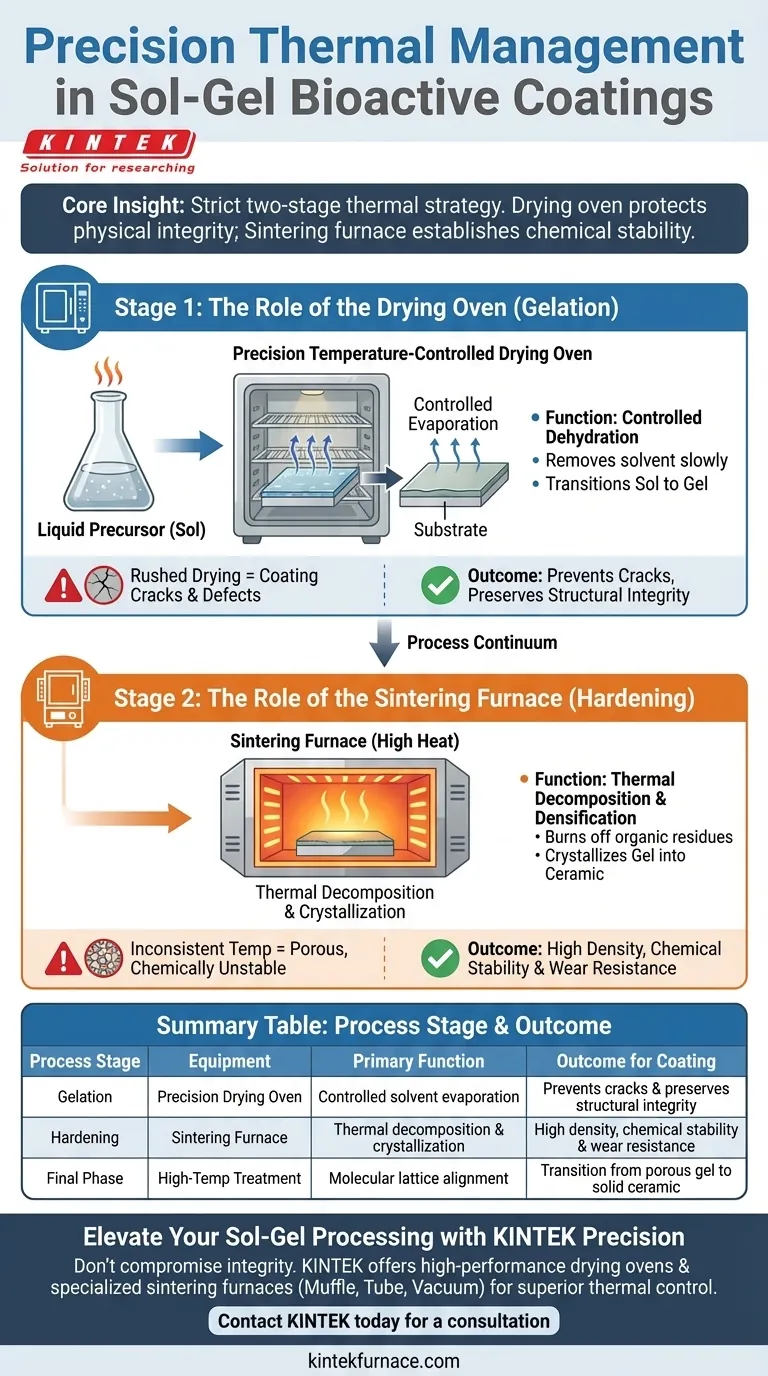

Precision thermal management is the defining factor in converting liquid precursors into durable bioactive coatings during the Sol-Gel process. The drying oven functions to slowly solidify the liquid film into a gel structure without cracking, while the sintering furnace provides the high heat necessary to crystallize that gel into a dense, wear-resistant ceramic.

Core Insight: The Sol-Gel process requires a strict two-stage thermal strategy: the drying oven protects physical integrity by managing evaporation rates, while the sintering furnace establishes chemical stability through densification.

Stage 1: The Role of the Drying Oven

Controlled Dehydration

The primary function of the precision temperature-controlled drying oven is the initial dehydration of the applied sol.

By carefully applying heat, the oven removes the solvent from the mixture. This transitions the material from a liquid "sol" state into a semi-solid "gel" network.

Preventing Structural Defects

The critical value of this equipment lies in its ability to regulate the rate of evaporation.

If the solvent evaporates too quickly, the film experiences significant shrinkage stress. This results in coating cracks and surface defects.

A precision oven ensures the process is slow and uniform, preserving the structural integrity of the coating before it enters the final hardening stage.

Stage 2: The Role of the Sintering Furnace

Thermal Decomposition and Crystallization

Once the gel layer is formed, the sintering furnace takes over to perform a high-temperature treatment.

This intense heat induces thermal decomposition, burning off organic residues remaining in the matrix. Simultaneously, it drives crystallization, forcing the molecules to align into a structured lattice.

Achieving Densification

The furnace transforms the porous gel layer into a dense ceramic phase.

Depending on the precursors used, this creates solid materials such as silica, zinc oxide, or hydroxyapatite.

Ensuring Durability

This final densification step is what grants the coating its functional properties.

By eliminating porosity and fusing the material, the furnace ensures the final coating possesses high chemical stability and significant wear resistance.

Understanding Process Risks

The effectiveness of these two stages relies entirely on thermal precision.

If the drying phase is rushed to save time, the coating will almost certainly develop micro-cracks, rendering the subsequent sintering step useless.

Conversely, if the sintering temperature is inconsistent, the ceramic phase will not fully densify, resulting in a coating that is chemically unstable and prone to premature wear.

Optimizing Your Thermal Strategy

To achieve a high-quality bioactive coating, you must view these two pieces of equipment as part of a single continuum.

- If your primary focus is surface integrity: Prioritize the precision and ramp-rate of your drying oven to ensure solvent evaporation is gradual enough to prevent cracking.

- If your primary focus is mechanical longevity: Ensure your sintering furnace is capable of sustaining the specific high temperatures required to achieve full density for your target ceramic (e.g., hydroxyapatite).

Control the heat, and you control the quality of the final ceramic interface.

Summary Table:

| Process Stage | Equipment | Primary Function | Outcome for Coating |

|---|---|---|---|

| Gelation | Precision Drying Oven | Controlled solvent evaporation | Prevents cracks & preserves structural integrity |

| Hardening | Sintering Furnace | Thermal decomposition & crystallization | High density, chemical stability & wear resistance |

| Final Phase | High-Temp Treatment | Molecular lattice alignment | Transition from porous gel to solid ceramic |

Elevate Your Sol-Gel Processing with KINTEK Precision

Don't let thermal inconsistency compromise the integrity of your bioactive coatings. Backed by expert R&D and manufacturing, KINTEK offers high-performance drying ovens and specialized sintering furnaces—including Muffle, Tube, and Vacuum systems—engineered for the rigorous demands of ceramic densification and thin-film stability. Whether you need standard lab high-temp furnaces or fully customizable solutions tailored to your unique research goals, KINTEK provides the thermal control necessary for superior chemical stability and wear resistance.

Ready to achieve flawless ceramic interfaces? Contact KINTEK today for a consultation.

Visual Guide

References

- Qin Rao, Shunli Zheng. Research Progress of the Coatings Fabricated onto Titanium and/or Titanium Alloy Surfaces in Biomaterials for Medical Applications for Anticorrosive Applications. DOI: 10.3390/coatings15050599

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What should be considered when choosing a muffle furnace for specific needs? Key Factors for Optimal Lab Performance

- What role does a muffle furnace play during the calcination of Ni/Al2O3 catalysts? Optimize Your Catalyst Stability

- Why is a muffle furnace used to bake reinforcement particles? Optimize Aluminum Matrix Composite Quality

- How are muffle furnaces utilized in dental laboratories? Essential for Sintering, Firing, and Casting

- What role does a laboratory muffle furnace play in analyzing organic matter degradation? Optimize Biomass Pretreatment

- Why is a laboratory muffle furnace core to CCT nanocatalyst prep? Optimize Your Calcination Results

- How is a high-temperature box furnace utilized during the calcination and sintering stages of SrVO3 precursors?

- Why is a muffle furnace critical for Barium Stannate (BSO) nanopowders? Achieve Precise Phase Purity