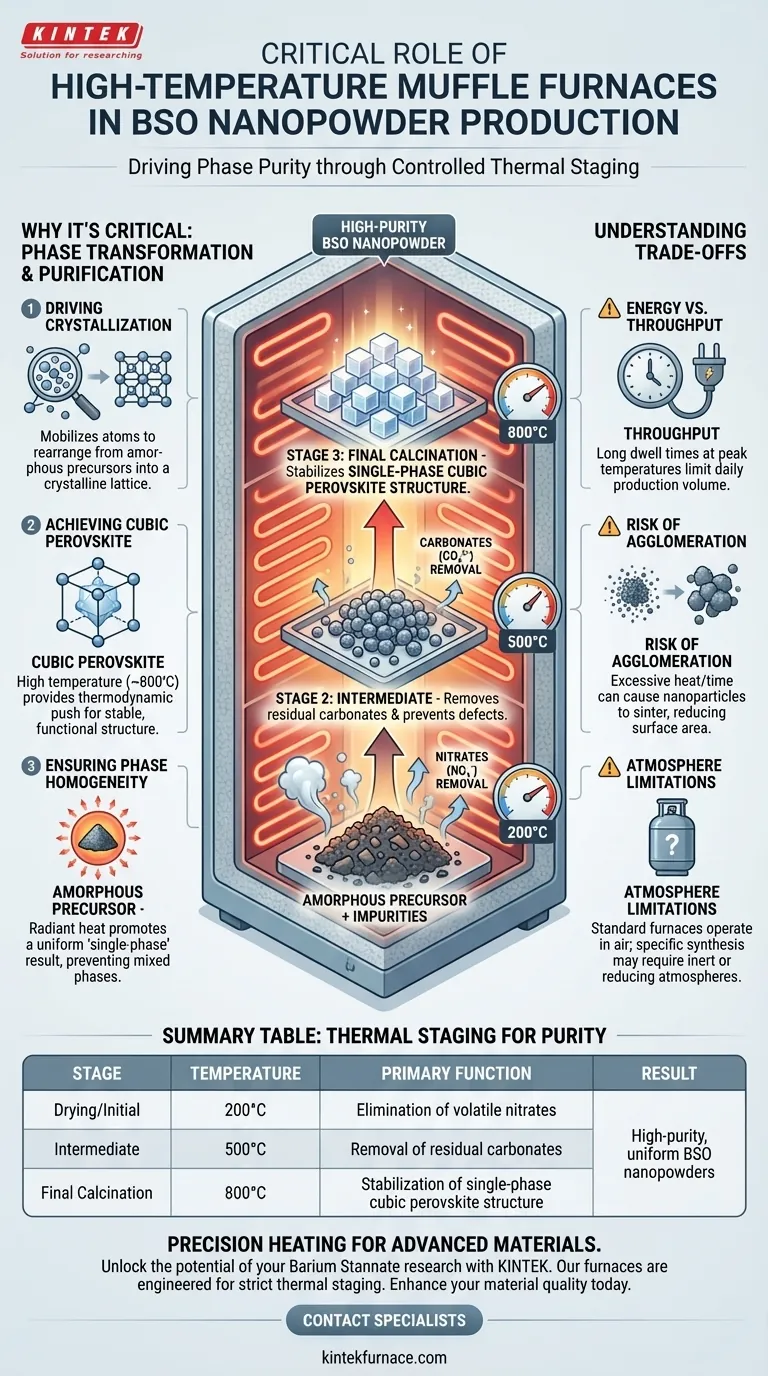

A laboratory high-temperature muffle furnace is the primary driver of phase purity in Barium Stannate (BSO) production. It provides the strictly controlled thermal environment necessary to convert amorphous precursors into a stable, crystalline material. Specifically, this equipment manages the critical calcination and annealing stages, ensuring the transformation into a single-phase cubic perovskite structure while effectively removing chemical impurities.

Core Takeaway Production of high-quality BSO nanopowders is not merely about reaching high temperatures; it is about controlled thermal staging. A muffle furnace allows for precise heating at specific intervals—such as 200°C, 500°C, and 800°C—to eliminate nitrates and carbonates before locking in the final crystal structure.

The Mechanism of Phase Transformation

The primary function of the muffle furnace in this context is to reorganize the atomic structure of the material. The BSO precursors start as a disordered mixture that must be forced into a specific lattice arrangement.

Driving Crystallization

Initial precursor materials are often amorphous, meaning they lack a defined long-range order. The thermal energy provided by the muffle furnace mobilizes atoms, allowing them to rearrange into an ordered crystalline lattice.

Achieving the Cubic Perovskite Structure

For Barium Stannate to function correctly in electronic or optical applications, it must achieve a specific "cubic perovskite" structure. The high-temperature environment at the upper limits of the process (around 800°C) provides the thermodynamic push required to stabilize this specific phase.

Ensuring Phase Homogeneity

Without uniform heating, the material might contain a mix of different phases or unreacted oxides. The muffle furnace surrounds the sample with radiant heat, promoting a "single-phase" result where the entire sample exhibits the uniform cubic structure.

Purification Through Thermal Staging

Creating pure BSO nanopowders requires removing the chemical byproducts left over from the synthesis process. The muffle furnace executes this through a series of thermal steps.

Stepwise Contaminant Removal

Impurities do not all burn off at once; they require different energy levels to vaporize. The furnace allows for dwelling at specific intermediate temperatures, such as 200°C and 500°C.

Eliminating Volatile Impurities

Common residuals from the precursor stage include carbonates and nitrates. If left in the material, these impurities would degrade the electrical properties of the final BSO powder. The furnace effectively oxidizes and removes these compounds before the final crystallization occurs.

Preventing Structural Defects

If the material is heated too quickly to the final temperature without these intermediate pauses, trapped gases from decomposing impurities can create defects. Controlled heating ensures these volatiles escape before the crystal lattice fully rigidifies.

Understanding the Trade-offs

While the high-temperature muffle furnace is essential, it introduces specific processing constraints that must be managed.

Energy Consumption vs. Throughput

High-temperature processing is energy-intensive and time-consuming. Achieving the perfect single-phase cubic structure requires long dwell times at peak temperatures, which limits the volume of material you can process per day.

Risk of Particle Agglomeration

While heat drives crystallization, excessive heat or prolonged exposure can cause the nanopowders to sinter (fuse) together prematurely. This increases the particle size and reduces the surface area, which may be detrimental depending on the final application.

Atmosphere Control Limitations

Standard muffle furnaces typically operate in an air atmosphere. If your specific BSO synthesis route requires an inert gas or reducing atmosphere to control oxygen vacancies, a standard muffle furnace may require modification or a specialized retort.

Making the Right Choice for Your Goal

To maximize the utility of your high-temperature muffle furnace for BSO nanopowders, you must align the thermal profile with your specific material requirements.

- If your primary focus is Phase Purity: Prioritize a protocol that ensures the final annealing stage reaches at least 800°C to guarantee the formation of the single-phase cubic perovskite structure.

- If your primary focus is Chemical Composition: Emphasize the intermediate dwell times (200°C and 500°C) to ensure the complete removal of carbonates and nitrates before densification begins.

Precise thermal control is the difference between a contaminated mixture and a high-performance Barium Stannate nanopowder.

Summary Table:

| Stage | Temperature | Primary Function |

|---|---|---|

| Drying/Initial | 200°C | Elimination of volatile nitrates |

| Intermediate | 500°C | Removal of residual carbonates |

| Final Calcination | 800°C | Stabilization of single-phase cubic perovskite structure |

| Result | N/A | High-purity, uniform BSO nanopowders |

Precision Heating for Advanced Materials

Unlock the full potential of your Barium Stannate research with KINTEK. Our high-temperature muffle furnaces are engineered for the strict thermal staging required to produce high-purity cubic perovskite structures.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you are refining nanopowders or developing new electronic ceramics, our laboratory furnaces are fully customizable to meet your unique thermal profiles.

Enhance your material quality today. Contact our specialists to find your solution!

Visual Guide

References

- Nehal Ashok Waghchoure, Halan Prakash. Removal of tetracycline antibiotic activity in water by stable cubic phase barium stannate-perovskite nanoparticles under energy-efficient blue light LED irradiation. DOI: 10.1039/d5ra02938d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the final considerations when choosing a muffle furnace? Ensure Long-Term Value and Safety

- What is the function of a laboratory box-type high-temperature furnace? Master AlCoCrFeNi2.1 Heat Treatment Evolution

- What are the thermal insulation materials used in muffle furnaces? Choose the Right Insulation for Efficiency and Durability

- Why is an automated high-temperature muffle furnace necessary for coating life assessment? Ensure Testing Precision

- How do a laboratory high-temperature box furnace and water quenching work together? Optimize High-Manganese Steel

- Why is a box muffle furnace required for In2O3 nanofibers? Expert Synthesis & Pre-Oxidation Guide

- What types of heat transfer occur in a box-type resistance furnace? Master Radiation and Convection for Optimal Heating

- Why is a high-temperature muffle furnace necessary for LLZO calcination? Master Phase Purity in Solid-State Electrolytes