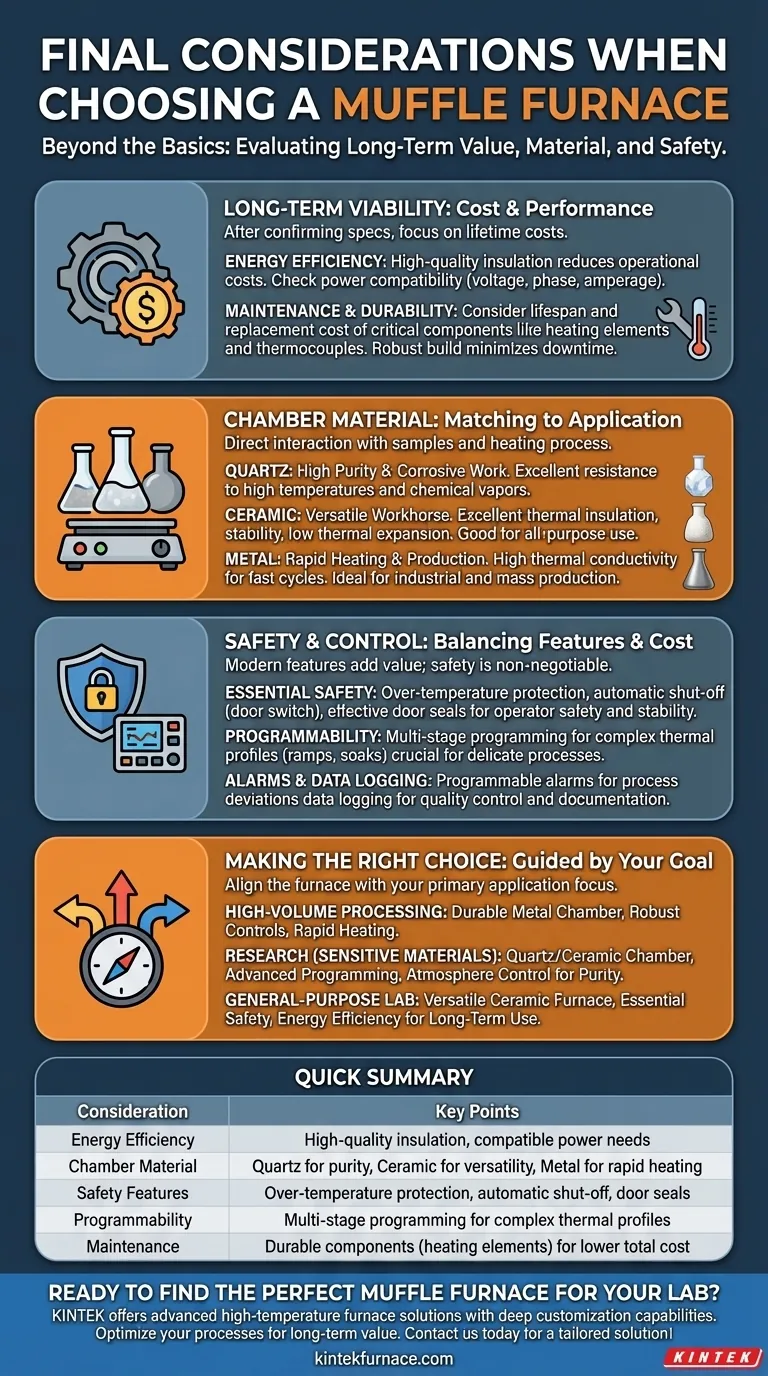

Once you have confirmed the basic requirements of temperature range and chamber size, the final considerations for selecting a muffle furnace shift to factors that determine long-term value. These final checks focus on operational costs, material compatibility, and the crucial aspects of safety and process control that will define the furnace's daily usability.

The best muffle furnace isn't just the one that gets hot enough; it's the one that aligns with your specific application's material needs, meets your lab's safety standards, and minimizes long-term operational costs through efficiency and durability.

Beyond the Spec Sheet: Evaluating Long-Term Viability

After confirming the basics, you must evaluate the factors that impact cost and performance over the furnace's entire lifespan.

Energy Efficiency and Power Needs

A furnace is an energy-intensive device. Choosing an efficient model with high-quality insulation directly reduces your long-term operational costs.

Also, confirm the furnace's power requirements (voltage, phase, and amperage) are compatible with your facility's electrical infrastructure to avoid costly modifications.

Maintenance and Durability

Consider the long-term costs associated with upkeep. Ask about the lifespan and replacement cost of critical components like heating elements and thermocouples.

A robust build quality, though potentially more expensive upfront, minimizes downtime and repair costs, ensuring a lower total cost of ownership.

Matching Chamber Material to Your Application

The material of the inner furnace chamber is not a trivial detail; it directly interacts with your samples and the heating process.

Quartz Chambers: For High Purity and Corrosive Work

Quartz offers excellent resistance to high temperatures and corrosion. This makes it the ideal choice for experiments where sample purity is paramount or when working with aggressive chemical vapors.

Ceramic Chambers: The Versatile Workhorse

Ceramic chambers provide excellent thermal insulation and stability. Their low thermal expansion makes them a reliable, all-purpose option for a wide range of applications, from chemical reactions to processing electronic components.

Metal Chambers: For Rapid Heating and Production

Metal bodies, prized for their thermal conductivity, allow for rapid heating and cooling cycles. This makes them highly suitable for high-temperature industrial heating and mass production environments where speed is critical.

Understanding the Trade-offs: Safety and Control

Modern features add significant value, but you must balance them against complexity and cost. Safety, however, is non-negotiable.

Essential Safety Features You Cannot Ignore

Your furnace must include foundational safety mechanisms. Look for over-temperature protection to prevent runaway heating and an automatic shut-off feature, often linked to a door switch.

High-quality insulation and effective door seals are not just for efficiency; they are critical for operator safety and temperature stability.

Programmability: From Setpoints to Complex Profiles

The controller is your primary interface. A basic controller allows you to set a target temperature and time.

More advanced models offer multi-stage programming, allowing you to create complex thermal profiles with different ramps, soaks, and temperature gradients. This is essential for delicate material synthesis or specific annealing processes.

The Value of Alarms and Data Logging

Consider if your process requires monitoring. Programmable alarms can alert you to process deviations, while integrated data logging provides a crucial record for quality control and research documentation.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary application.

- If your primary focus is high-volume processing: Prioritize a durable metal chamber with robust, simple controls for rapid heating and maximum uptime.

- If your primary focus is research with sensitive materials: Invest in a quartz or ceramic chamber with advanced programming and atmosphere control for process purity and repeatability.

- If your primary focus is general-purpose use in a shared lab: Select a versatile ceramic furnace with all essential safety features and strong energy efficiency to manage long-term operational costs.

This careful evaluation ensures your muffle furnace becomes a reliable, long-term asset for your work.

Summary Table:

| Consideration | Key Points |

|---|---|

| Energy Efficiency | High-quality insulation, compatible power needs to reduce operational costs |

| Chamber Material | Quartz for purity, ceramic for versatility, metal for rapid heating |

| Safety Features | Over-temperature protection, automatic shut-off, door seals |

| Programmability | Multi-stage programming for complex thermal profiles |

| Maintenance | Durable components like heating elements for lower total cost of ownership |

Ready to find the perfect muffle furnace for your lab? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed with strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need energy-efficient designs, specific chamber materials, or enhanced safety features, we can help optimize your processes for long-term value. Contact us today to discuss your needs and get a tailored solution!

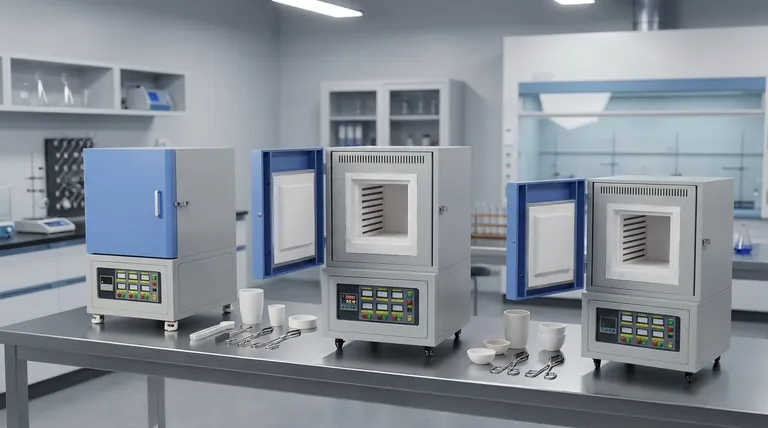

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation