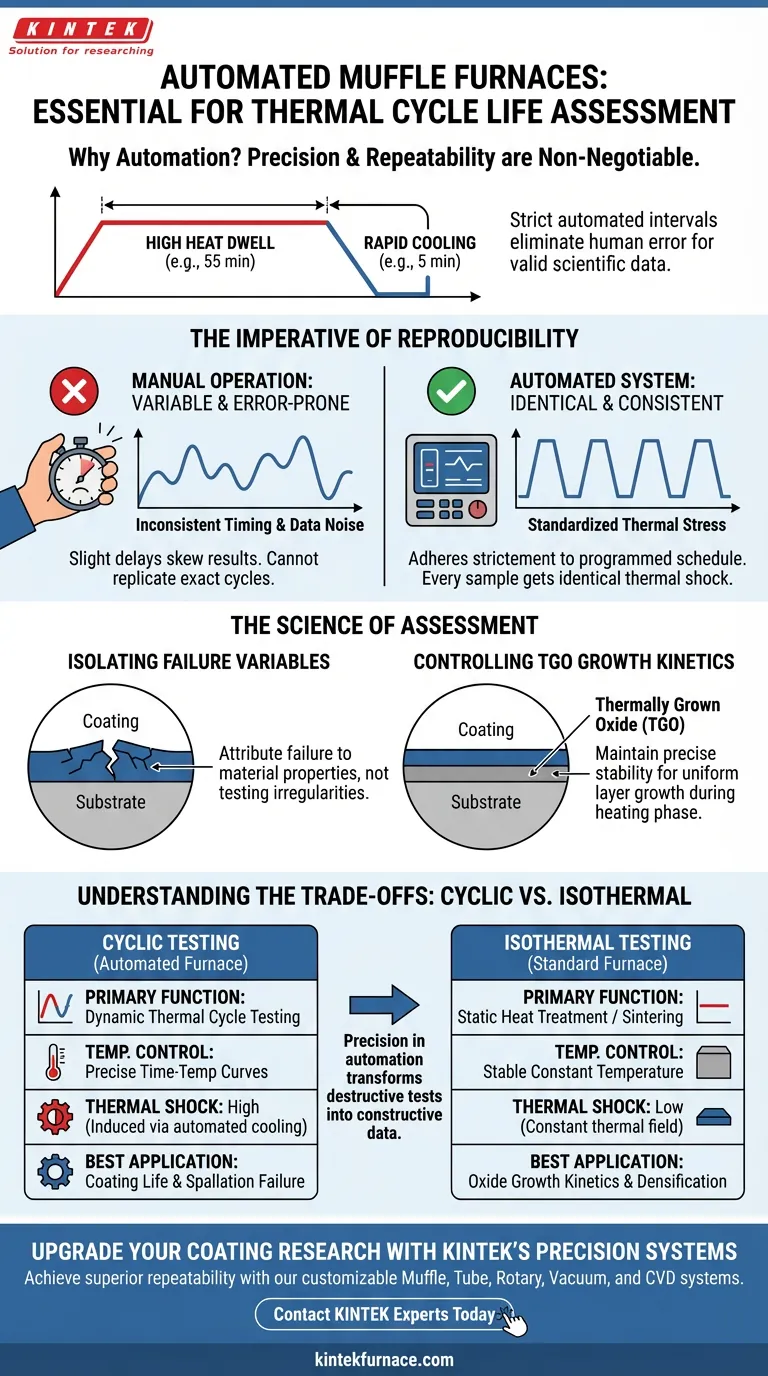

An automated program-controlled high-temperature muffle furnace is necessary to execute precise time-temperature curves that manual operation cannot replicate. By strictly automating specific intervals—such as a rigorous cycle of 55 minutes at high heat followed by 5 minutes of rapid cooling—this equipment eliminates human error, ensuring that every coating sample is subjected to identical thermal stress for valid scientific assessment.

Core Takeaway: The assessment of thermal cycle life relies on the repeatability of stress. Without the strict temporal precision provided by automation, variations in heating and cooling times would introduce data noise, making it impossible to distinguish between a coating's intrinsic failure properties and inconsistent testing conditions.

The Imperative of Reproducibility

Eliminating Human Variability

In manual testing scenarios, slight delays in removing a sample or fluctuations in timing can skew results. An automated system adheres strictly to the programmed schedule, ensuring the transition between heating and cooling happens at the exact same second for every cycle.

Standardizing Thermal Stress

Thermal cycle life is assessed by measuring how well a coating withstands repeated expansion and contraction. The furnace ensures that the thermal shock—the rapid change in temperature—is consistent across all samples. This allows researchers to attribute failure specifically to the material's properties rather than irregularities in the testing procedure.

The Science of Thermal Cycle Assessment

Isolating Failure Variables

The primary goal of these tests is often to understand spallation failure (when the coating peels off). By guaranteeing identical cycles, researchers can scientifically compare how different variables, such as pre-oxidation states, affect the coating's lifespan. If the thermal cycle varies, it becomes impossible to correlate specific pre-conditions with the actual failure point.

Controlling Oxide Growth Kinetics

While the cycle tests physical adherence, the high-temperature dwell time drives chemical changes. During the heating phase, elements like aluminum or chromium in the bond coat react to form a Thermally Grown Oxide (TGO) layer. Automated furnaces maintain the precise stability required to grow these layers uniformly, ensuring that the chemical degradation matches the physical stress of the cycle.

Understanding the Trade-offs

Cyclic vs. Isothermal Testing

It is critical to distinguish between cyclic testing and isothermal (constant temperature) testing. While a standard high-temperature furnace can handle simple isothermal oxidation (long-term heating without fluctuations), it cannot simulate the mechanical strain induced by rapid temperature changes. Using a non-programmable furnace for cycle life assessment is fundamentally flawed, as it lacks the ability to automate the rapid cooling phases that trigger mechanical failure.

Complexity and Specificity

These furnaces are specialized tools designed for dynamic testing. They provide less value for simple tasks, such as bulk sintering or increasing coating density through static heating. If the goal is merely to improve bonding strength via atomic diffusion without stress testing, a standard box resistance furnace may be more cost-effective.

Making the Right Choice for Your Goal

To ensure your equipment matches your testing objectives, consider the following:

- If your primary focus is Thermal Cycle Life Assessment: You strictly require an automated, program-controlled furnace to replicate specific heating/cooling curves and induce consistent thermal shock.

- If your primary focus is Isothermal Oxidation or Sintering: A standard high-temperature box furnace is sufficient to provide the stable thermal field needed for TGO growth kinetics or coating densification.

Precision in automation is the only way to transform a destructive test into a constructive data point.

Summary Table:

| Feature | Automated Program-Controlled Furnace | Standard Isothermal Furnace |

|---|---|---|

| Primary Function | Dynamic Thermal Cycle Testing | Static Heat Treatment/Sintering |

| Temperature Control | Precise Time-Temperature Curves | Stable Constant Temperature |

| Thermal Shock | High (Induced via automated cooling) | Low (Constant thermal field) |

| Human Error | Eliminated via programmed intervals | Possible during manual timing |

| Best Application | Coating Life & Spallation Failure | Oxide Growth Kinetics & Densification |

Upgrade Your Coating Research with KINTEK’s Precision Systems

Don’t let manual timing errors compromise your scientific data. KINTEK’s automated high-temperature furnaces are engineered to deliver the rigorous, repeatable thermal cycles required for valid thermal cycle life assessment.

Backed by expert R&D and world-class manufacturing, we offer a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific laboratory requirements. Whether you are studying TGO growth kinetics or testing coating spallation, our systems provide the stability and control your research demands.

Ready to achieve superior repeatability in your lab?

Visual Guide

References

- He Qin, Xiaoming You. Investigation of the Interface Diffusion Layer’s Impact on the Thermal Cycle Life of PS-PVD Thermal Barrier Coatings. DOI: 10.3390/coatings15010013

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What is the role of a high-temperature muffle furnace in the annealing process of para-aramid fibers?

- What is the function of a muffle furnace in NiFe2O4/biochar prep? Optimize Your Composite Synthesis

- How do muffle furnaces ensure temperature uniformity? Discover Key Design Principles for Precise Heating

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- Why is a laboratory high-temperature oven necessary for heterogeneous decatungstate catalysts? Ensure Structural Fixation

- What temperature information is displayed simultaneously on the controls? Monitor Real-Time and Target Temperatures for Precision

- What is the function of a muffle furnace in the preparation of phosphate glass raw materials? Expert Insights

- What are the benefits of using a box furnace? Versatile, Uniform Heating for Your Lab