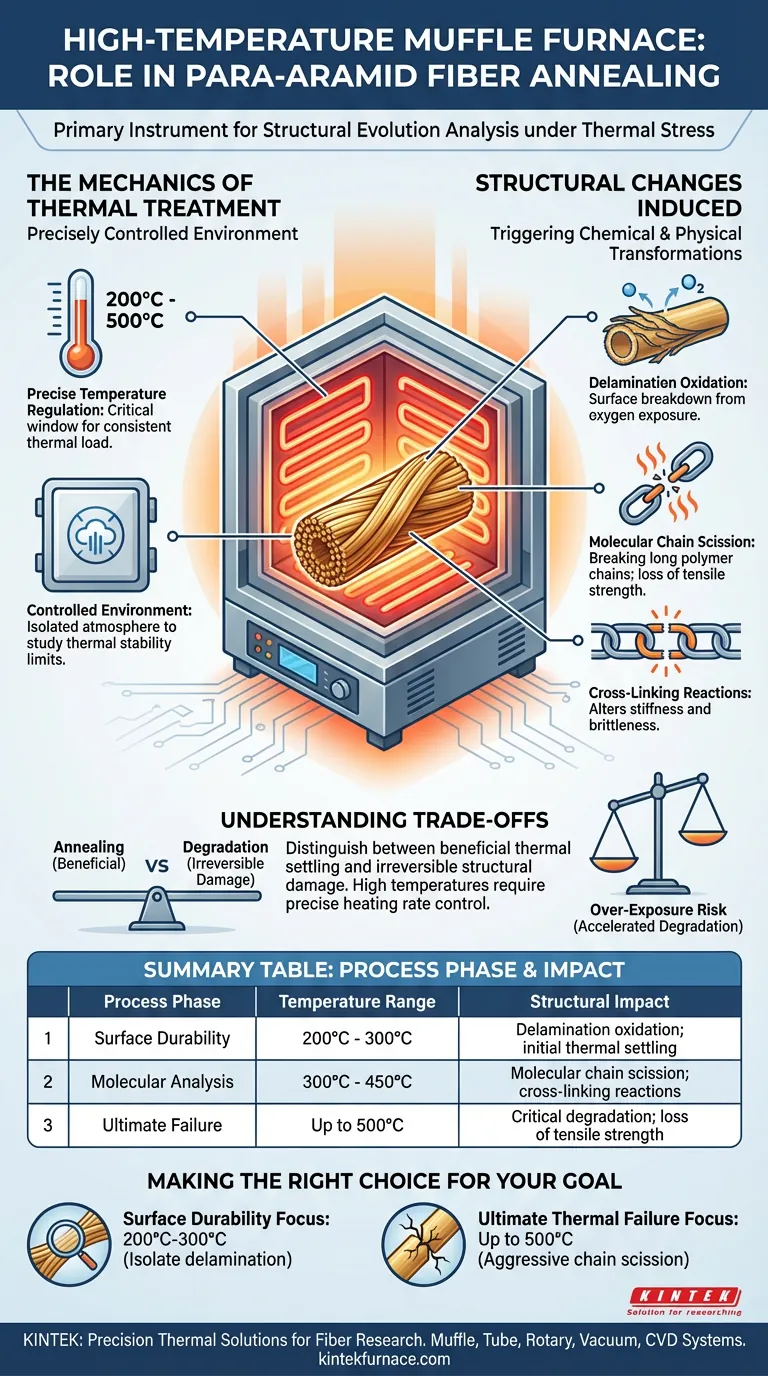

A high-temperature muffle furnace serves as the primary instrument for inducing and analyzing structural evolution in para-aramid fibers under thermal stress. It creates a precisely controlled environment, typically between 200°C and 500°C, to trigger specific chemical and physical transformations necessary for material research.

The core function of the furnace is to simulate high-temperature degradation, allowing researchers to isolate how heat impacts the fiber's molecular integrity through oxidation, chain scission, and cross-linking.

The Mechanics of Thermal Treatment

Precise Temperature Regulation

The fundamental role of the muffle furnace is to maintain exact temperature gradients.

For para-aramid fibers, this generally involves operating within a critical window of 200°C to 500°C.

This precision ensures that the thermal load applied to the material is consistent and reproducible across experiments.

Creating a Controlled Environment

Beyond simple heating, the furnace provides a stable atmosphere for the fibers.

This isolation is necessary to study how the physical and chemical properties of the material evolve solely in response to temperature.

It acts as the core equipment for determining the thermal stability limits of the fiber.

Structural Changes Induced by the Furnace

Delamination Oxidation

One of the primary structural changes induced by the furnace is delamination oxidation.

This process involves the breakdown of the fiber's surface layers due to high-temperature oxygen exposure.

Monitoring this helps researchers understand how the fiber's exterior durability degrades over time.

Molecular Chain Scission

The thermal energy supplied by the furnace triggers molecular chain scission.

This is the breaking of the long polymer chains that give para-aramid fibers their characteristic high strength.

Studying this mechanism is vital for predicting the loss of tensile strength in high-heat applications.

Cross-Linking Reactions

Simultaneously, the heat treatment can induce cross-linking reactions between polymer chains.

While chain scission weakens the material, cross-linking can alter its stiffness and brittleness.

The furnace allows for the precise observation of the competition between these degrading and restructuring forces.

Understanding the Trade-offs in Thermal Analysis

Annealing vs. Degradation

While the term "annealing" implies a treatment to improve properties, in the context of para-aramid research at these temperatures, the focus is often on degradation.

The furnace is used to push the material to its limits to identify failure points.

Researchers must distinguish between beneficial thermal settling and irreversible structural damage.

The Risk of Over-Exposure

Operating at the higher end of the 500°C spectrum accelerates degradation significantly.

Excessive heat can lead to rapid total loss of mechanical properties, making the data difficult to capture accurately.

Precise control of the heating rate is essential to capture the nuances of the structural evolution before total failure occurs.

Making the Right Choice for Your Goal

When utilizing a high-temperature muffle furnace for para-aramid fiber analysis, align your parameters with your specific research objectives.

- If your primary focus is analyzing surface durability: Concentrate on the lower temperature range (200°C–300°C) to isolate the effects of delamination oxidation without triggering massive chain scission.

- If your primary focus is determining ultimate thermal failure: Utilize the upper temperature range (up to 500°C) to aggressively induce molecular chain scission and cross-linking reactions.

By mastering the thermal environment within the muffle furnace, you convert raw heat into critical data regarding the lifecycle and limitations of high-performance fibers.

Summary Table:

| Process Phase | Temperature Range | Structural Impact on Fibers |

|---|---|---|

| Surface Durability | 200°C - 300°C | Delamination oxidation and initial thermal settling |

| Molecular Analysis | 300°C - 450°C | Molecular chain scission and cross-linking reactions |

| Ultimate Failure | Up to 500°C | Critical degradation and loss of tensile strength |

Precision Thermal Solutions for Fiber Research

Maximize your material research accuracy with KINTEK’s high-performance laboratory solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems designed to provide the precise temperature gradients required for analyzing para-aramid fibers and other high-performance materials.

Whether you need standard equipment or a customizable system tailored to your unique research needs, our furnaces ensure consistent, reproducible results. Contact us today to discuss how our lab high-temperature furnaces can optimize your annealing and degradation studies!

Visual Guide

References

- Chunyan Zhu, Chen Yang. Testing and characterization of high-temperature degradation performanceof para-aramid fibres. DOI: 10.35530/it.075.01.2023115

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a laboratory muffle furnace necessary for nickel-based superalloys? Expert Stabilization & Hardening Guide

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What role does a muffle furnace play in the synthesis of Si@Al adsorbents? Master Precise Thermal Transformation

- How does a stainless steel reactor function within a muffle furnace for PET to graphene? Master Carbon Synthesis

- What function does a muffle furnace perform during the air calcination of ZnO-Co3O4? Optimize Your Nanocomposites

- What features are included in the temperature control console of box furnaces? Achieve Precision and Repeatability in Thermal Processing

- What role does a high-temperature laboratory muffle furnace play in Indium-doped LLZO? Optimize Solid Electrolyte Synthesis

- What materials can be processed in a muffle furnace? Explore Versatile High-Temp Solutions