A high-temperature laboratory muffle furnace acts as the fundamental processing unit for converting raw chemical precursors into functional Indium-doped LLZO solid electrolytes. It executes the critical thermal cycles of calcination and sintering, transforming loose powders into a dense, conductive ceramic capable of supporting solid-state battery performance.

Precision in thermal processing is the difference between a loose powder and a high-performance electrolyte. The muffle furnace facilitates the essential phase changes and densification required to achieve ionic conductivity benchmarks of 1 mS/cm.

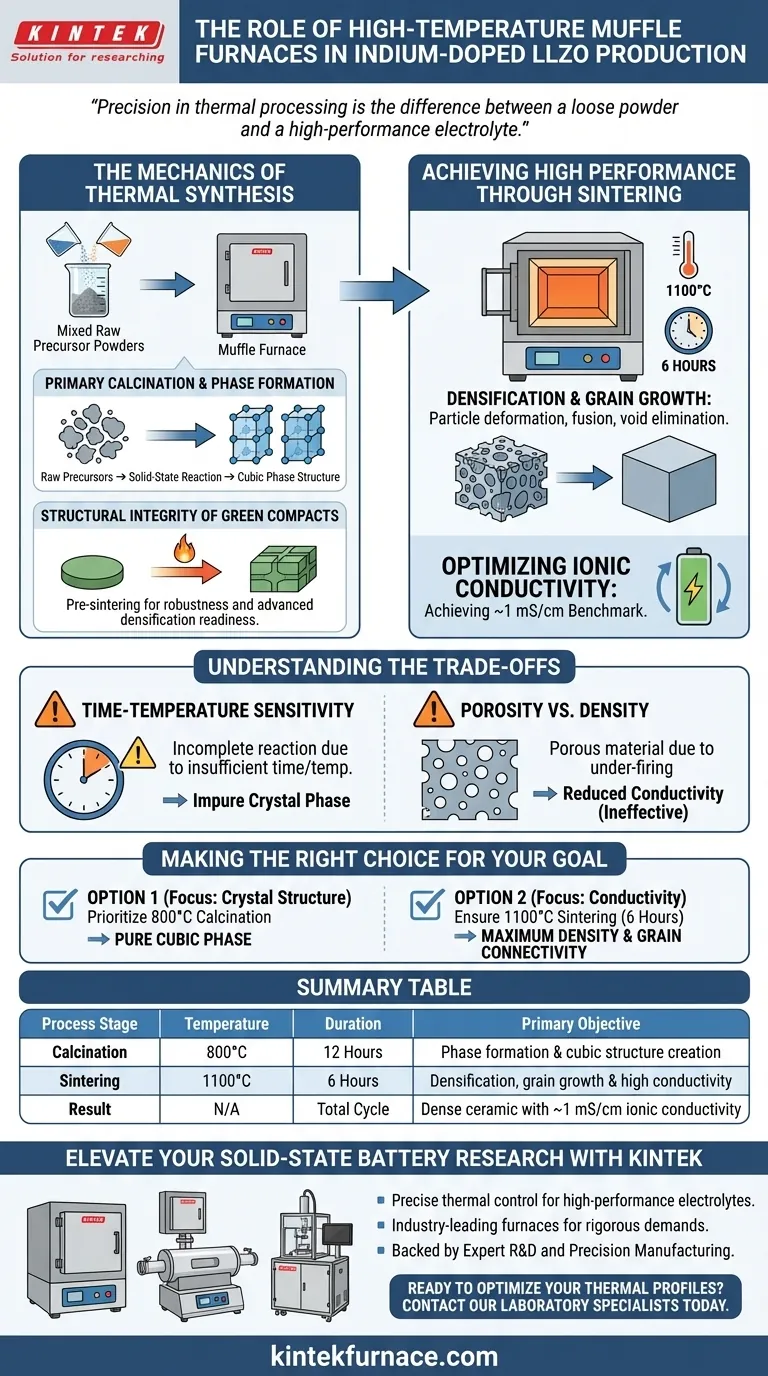

The Mechanics of Thermal Synthesis

The production of Indium-doped LLZO is not merely about heating; it is about controlling chemical reactions and physical structural changes through precise thermal profiles.

Primary Calcination and Phase Formation

The initial role of the furnace is to drive the solid-state reaction between raw precursors. By maintaining a temperature of 800°C for 12 hours, the furnace supplies the energy needed for these materials to react chemically.

This step is responsible for creating the cubic phase structure. Without this specific crystal arrangement, the material cannot effectively conduct lithium ions.

Structural Integrity of Green Compacts

Before the final hardening, the furnace plays a role in "pre-sintering" cold-pressed green compacts. Heating these pressed powders under atmospheric pressure facilitates preliminary particle bonding.

This improves the structural integrity of the material. It ensures the compact is robust enough to withstand subsequent handling or advanced densification processes like high-pressure hot re-pressing.

Achieving High Performance through Sintering

Once the chemical phase is established, the furnace's role shifts to altering the physical microstructure of the material.

Densification and Grain Growth

To create a usable solid electrolyte, the furnace temperature is raised to 1100°C for a duration of 6 hours.

This high-heat environment triggers significant particle deformation and grain growth. The individual particles fuse together, eliminating voids and resulting in a highly dense ceramic body.

Optimizing Ionic Conductivity

The ultimate goal of using a muffle furnace in this context is to maximize performance. The density achieved during the 1100°C sintering cycle is directly linked to the material's electrical properties.

Proper execution of this stage yields a solid electrolyte with ionic conductivity reaching 1 mS/cm. This level of conductivity is critical for the practical application of solid-state batteries.

Understanding the Trade-offs

While the muffle furnace is essential, the process requires strict adherence to specific parameters to avoid processing failures.

Time-Temperature Sensitivity

The specific protocols (12 hours at 800°C and 6 hours at 1100°C) are not arbitrary. Insufficient time or temperature at the calcination stage results in an incomplete reaction and an impure crystal phase.

Porosity vs. Density

Similarly, under-firing during the sintering stage prevents adequate grain growth. This leaves the material porous rather than dense, drastically reducing its ability to conduct ions and rendering the electrolyte ineffective.

Making the Right Choice for Your Goal

To maximize the utility of your muffle furnace for LLZO production, you must tailor your thermal profile to the specific material characteristic you are trying to optimize.

- If your primary focus is Crystal Structure: Prioritize the precision of the 800°C calcination cycle to ensure a pure cubic phase formation.

- If your primary focus is Conductivity: Ensure the sintering cycle holds strictly at 1100°C for the full 6 hours to achieve maximum density and grain connectivity.

Mastering these thermal parameters is the key to unlocking the full potential of Indium-doped LLZO electrolytes.

Summary Table:

| Process Stage | Temperature | Duration | Primary Objective |

|---|---|---|---|

| Calcination | 800°C | 12 Hours | Phase formation & cubic structure creation |

| Sintering | 1100°C | 6 Hours | Densification, grain growth & high conductivity |

| Result | N/A | Total Cycle | Dense ceramic with ~1 mS/cm ionic conductivity |

Elevate Your Solid-State Battery Research with KINTEK

Precise thermal control is the difference between an inert powder and a high-performance electrolyte. KINTEK provides industry-leading muffle, tube, and vacuum furnace systems specifically designed to meet the rigorous demands of solid-state electrolyte synthesis like Indium-doped LLZO.

Backed by expert R&D and precision manufacturing, our high-temperature laboratory furnaces offer the uniformity and stability required for critical phase formation and densification. Whether you need a standard muffle furnace or a fully customized CVD system, KINTEK empowers your lab with the tools to reach 1 mS/cm conductivity benchmarks consistently.

Ready to optimize your thermal profiles? Contact our laboratory specialists today to find the perfect heating solution for your unique research needs.

Visual Guide

References

- Alaa Alsawaf, Miriam Botros. Influence of In‐Doping on the Structure and Electrochemical Performance of Compositionally Complex Garnet‐Type Solid Electrolytes. DOI: 10.1002/sstr.202400643

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why is a box muffle furnace utilized for LMCs? Enhance Interface Bonding and Atomic Diffusion

- Why is a high-temperature Muffle Furnace required for SiNW manufacturing? Optimize Solid-State Dewetting Processes

- What is the role of a Muffle Furnace in the preparation of biochar from Miscanthus sinensis? Master Pyrolysis Control

- What is the purpose of a high-temperature muffle furnace for rare earth oxalate calcination? Achieve High-Purity REOs

- What role does a laboratory muffle furnace play in the industrial analysis of plastic waste? Optimizing Pyrolysis Yield

- What precautions should be taken when handling items inside the muffle furnace? Ensure Safety and Protect Your Equipment

- How are industrial-grade high-temperature muffle furnaces utilized in experimental archaeology? Unlock Ancient Tech

- Why is a muffle furnace critical for Barium Stannate (BSO) nanopowders? Achieve Precise Phase Purity