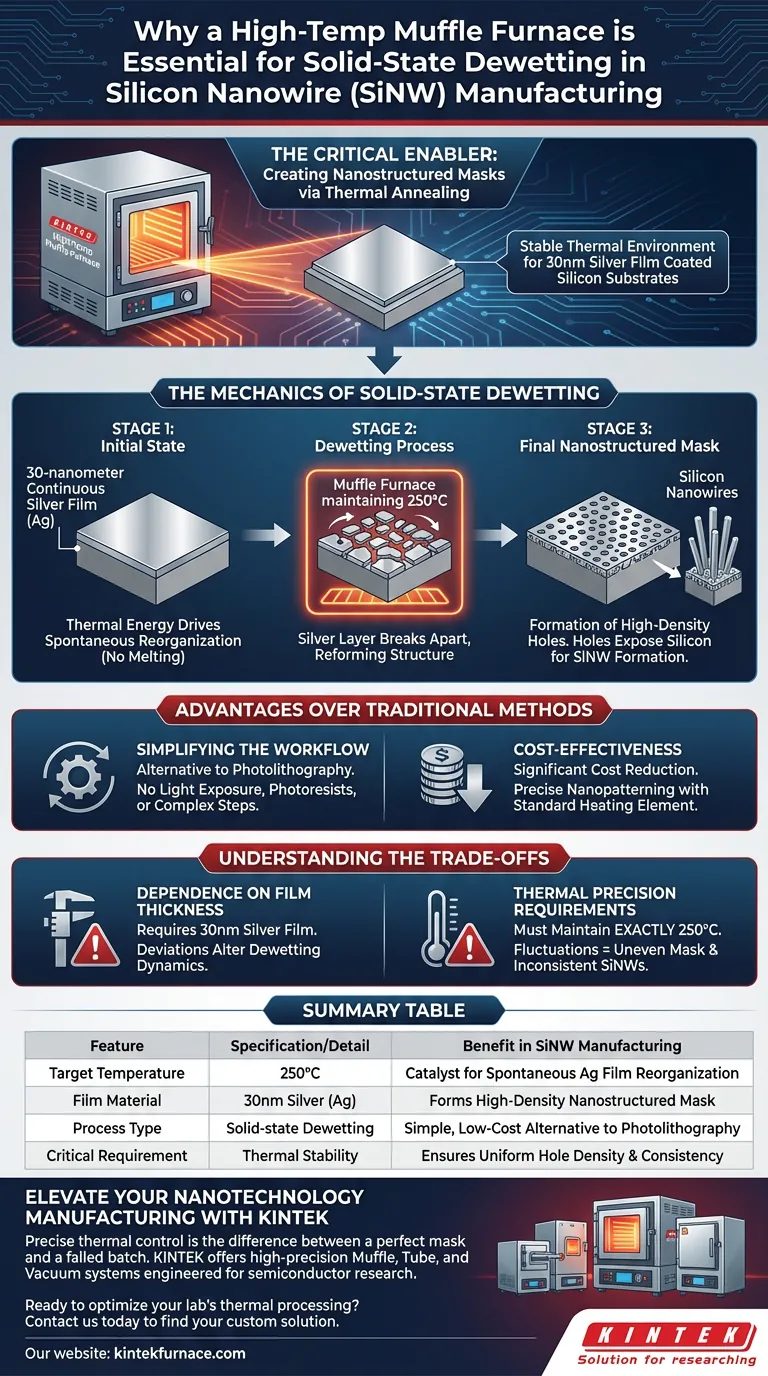

A high-temperature Muffle Furnace is the critical enabler for creating nanostructured masks through thermal annealing. It provides the stable thermal environment required to heat silicon substrates coated with a 30-nanometer silver film. This specific application of heat triggers the physical phenomenon known as solid-state dewetting, which is essential for defining the structure of Silicon Nanowires.

The Muffle Furnace maintains a precise temperature of 250°C to transform a continuous silver film into a nanostructured mask with high-density holes. This process effectively replaces complex photolithography, offering a simpler and more cost-effective route to high-precision nanopatterning.

The Mechanics of Solid-State Dewetting

Transforming the Silver Film

The process begins with a silicon substrate coated in a continuous 30-nanometer silver film.

Inside the furnace, the silver is not melted but rather annealed. This thermal energy causes the thin film to spontaneously evolve and reorganize its structure.

Creating the Nanostructured Mask

As the dewetting process occurs, the continuous silver layer breaks apart.

It reforms into a mask characterized by high-density holes. These holes expose the underlying silicon in a specific pattern, which defines where the Silicon Nanowires will eventually be formed.

The Role of Temperature Stability

The Muffle Furnace is required specifically to maintain a controlled environment of 250°C.

This consistent temperature is the catalyst that drives the dewetting process. Without this precise thermal control, the silver film would not evolve into the necessary mask structure.

Advantages Over Traditional Methods

Simplifying the Workflow

Standard semiconductor manufacturing often relies on photolithography to create patterns.

Solid-state dewetting in a Muffle Furnace serves as a simple alternative to this traditional approach. It achieves similar patterning results without the need for light exposure, photoresists, or complex development steps.

Cost-Effectiveness

By removing the need for photolithography equipment, this method significantly reduces manufacturing costs.

It allows for precise nanopatterning using only a thin silver film and a standard heating element.

Understanding the Trade-offs

Dependence on Film Thickness

The process described relies specifically on a 30-nanometer silver film.

Deviating from this specific thickness may alter the dewetting dynamics. If the film is too thick or too thin, it may not form the high-density holes required for effective masking.

Thermal Precision Requirements

While the method is simple, it is highly sensitive to temperature accuracy.

The furnace must maintain exactly 250°C. Fluctuations in temperature could result in an uneven mask, leading to inconsistent Silicon Nanowire structures.

Making the Right Choice for Your Project

When integrating a Muffle Furnace for solid-state dewetting, consider your specific manufacturing goals:

- If your primary focus is cost reduction: Utilize this method to eliminate the high overhead and complexity associated with traditional photolithography steps.

- If your primary focus is process consistency: Ensure your Muffle Furnace is calibrated to maintain a strict 250°C environment to guarantee uniform mask formation.

This approach transforms a standard heating process into a powerful, low-cost tool for precision nanotechnology.

Summary Table:

| Feature | Specification/Detail | Benefit in SiNW Manufacturing |

|---|---|---|

| Target Temperature | 250°C | Catalyst for spontaneous silver film reorganization |

| Film Material | 30nm Silver (Ag) | Forms the high-density nanostructured mask |

| Process Type | Solid-state Dewetting | Simple, low-cost alternative to photolithography |

| Critical Requirement | Thermal Stability | Ensures uniform hole density and mask consistency |

Elevate Your Nanotechnology Manufacturing with KINTEK

Precise thermal control is the difference between a perfect nanostructured mask and a failed batch. At KINTEK, we understand the rigorous demands of solid-state dewetting and Silicon Nanowire (SiNW) production.

Backed by expert R&D and world-class manufacturing, we provide high-precision Muffle, Tube, and Vacuum systems specifically engineered for semiconductor research and nanostructuring. Whether you require a standard benchtop furnace or a fully customizable high-temp system tailored to your unique film thickness and annealing parameters, KINTEK delivers the reliability you need to reduce costs and improve process consistency.

Ready to optimize your lab’s thermal processing? Contact us today to find your custom solution.

Visual Guide

References

- Te‐Hua Fang, Zhi‐Jun Zhao. Pd-Decorated SnO2 Nanofilm Integrated on Silicon Nanowires for Enhanced Hydrogen Sensing. DOI: 10.3390/s25030655

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How can the front panel of the box furnace be configured? Optimize Temperature Control for Your Lab

- What is the core function of a muffle furnace in mesoporous silica prep? Master Template Removal & Calcination

- What role does a high-temperature muffle furnace play during the carbonization of fish scales? Achieve Thermal Precision

- What are the thermal insulation material categories for muffle furnaces? Choose the Best for Your Lab

- What are the key operational features of modern muffle furnaces? Enhance Precision and Efficiency in Your Lab

- What makes uniform heating important in a muffle furnace? Ensure Precise, Reliable Results Every Time

- What are some general-purpose uses of a muffle furnace? Essential for High-Purity Material Processing

- What safety features are associated with box furnaces? Essential Protection for Your Laboratory Processes