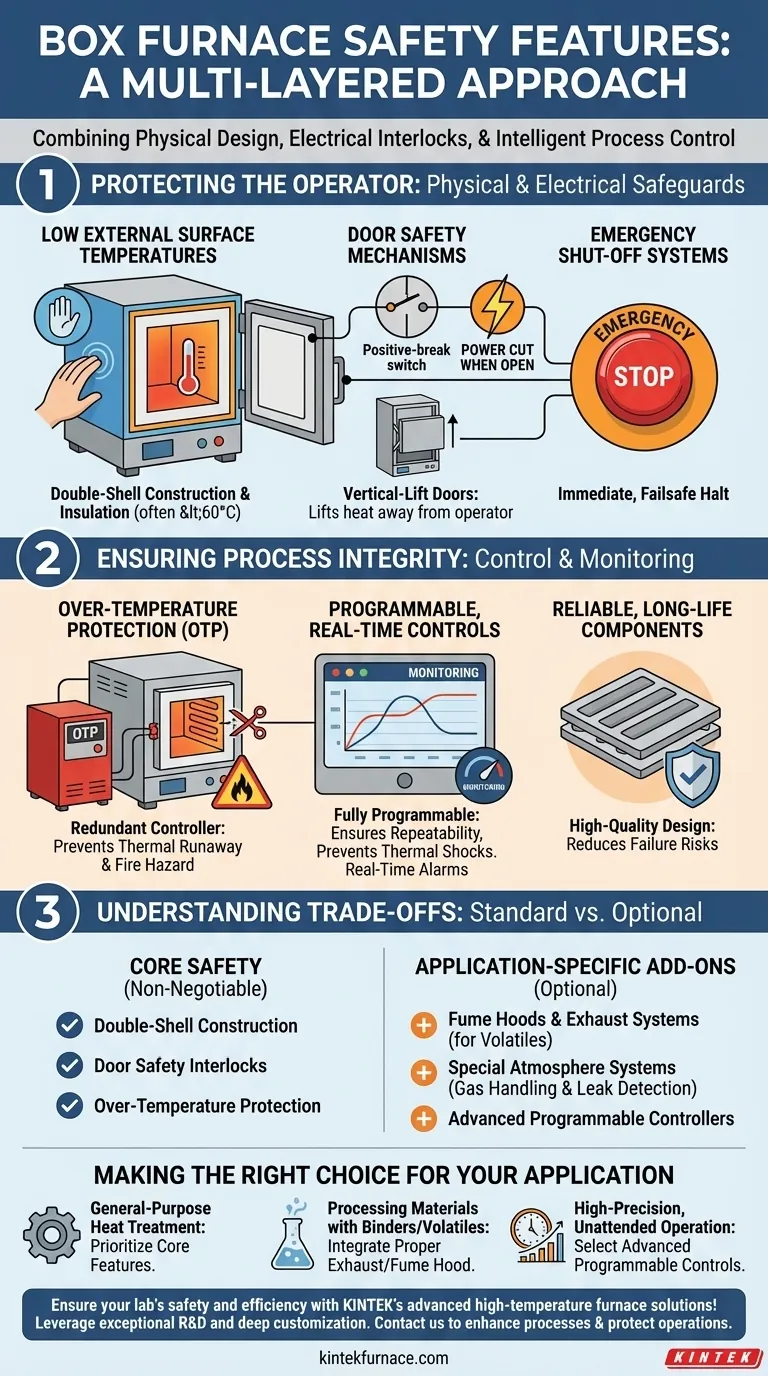

At their core, box furnaces integrate safety through a multi-layered approach combining physical design, electrical interlocks, and intelligent process control. Key features include double-shell construction to maintain low external temperatures, positive-break door switches that cut power when the door is opened, and over-temperature protection circuits to prevent runaway heating. These systems work in concert to protect the operator, the equipment, and the materials being processed.

Modern furnace safety is not a single feature but a comprehensive system. It is designed to mitigate risks from high temperatures, electrical hazards, and process byproducts through redundant physical, electrical, and software-based controls.

Protecting the Operator: Physical and Electrical Safeguards

The most immediate risks in furnace operation involve high temperatures and high voltage. Modern designs address these directly through engineered physical and electrical barriers.

Low External Surface Temperatures

A primary concern is preventing accidental burns from touching the furnace exterior.

Box furnaces use a double-shell construction with a significant air gap and high-quality insulation between the inner heating chamber and the outer casing. This design allows for rapid internal heat-up while ensuring the external surfaces remain cool and safe to touch, often below 60°C even when operating at very high temperatures.

Door Safety Mechanisms

The furnace door is the main point of interaction and potential exposure to extreme heat.

Most furnaces are equipped with a positive-break safety switch or interlock. This is a critical electrical feature that automatically cuts power to the heating elements the moment the door is opened, preventing operator exposure to direct radiant heat and electrical hazards.

Furthermore, some models feature vertical-lift doors. This design is inherently safer as it lifts the hot inner face of the door up and away from the operator, unlike a swing-out door that can radiate significant heat toward the user.

Emergency Shut-Off Systems

In the event of a malfunction or emergency, operators need a way to immediately halt the entire system.

Nearly all modern furnaces include a prominent emergency shut-off button. This control bypasses all other software and circuitry to cut all power to the furnace, providing a final, failsafe method of stopping operation.

Ensuring Process Integrity: Control and Monitoring

Beyond direct operator safety, robust process control is essential for preventing equipment damage and sample loss, which are safety concerns in their own right.

Over-Temperature Protection (OTP)

The single most important process safety feature is the Over-Temperature Protection circuit.

This is a separate, redundant temperature controller that constantly monitors the furnace chamber. If the main controller fails and the temperature exceeds a user-set safety limit, the OTP circuit independently cuts power to the heating elements, preventing thermal runaway that could destroy the sample, the furnace, and create a fire hazard.

Programmable, Real-Time Controls

Predictable and reliable operation is a cornerstone of safety.

Advanced digital controllers allow for fully programmable control of heating and cooling rates. This process repeatability ensures there are no thermal shocks or unexpected temperature spikes. Real-time monitoring provides immediate feedback on system status and can trigger alarms if parameters deviate from the setpoint.

Reliable, Long-Life Components

Component failure is a primary cause of unsafe conditions.

Manufacturers prioritize highly reliable designs using premium components, such as modular plate heating elements, which are known for their longevity. Sturdy construction and quality parts reduce the likelihood of unexpected electrical or mechanical failures during high-temperature operation.

Understanding the Trade-offs: Standard vs. Optional Features

Not all safety features are standard on every model. Understanding the difference is key to matching a furnace to your specific application and risk profile.

Core Safety is Non-Negotiable

Features like double-shell construction, door safety interlocks, and Over-Temperature Protection are fundamental to safe design. These should be considered standard, non-negotiable features on any modern box furnace you are evaluating.

Application-Specific Add-Ons

For processes involving potentially hazardous materials, additional features are required. Fume hoods and dedicated local exhaust systems are essential for safely managing and venting volatile materials, off-gassing binders, or other fumes generated during heating.

Special Atmospheres Require Special Systems

If your process requires a modified atmosphere (e.g., nitrogen, argon), you must have a furnace equipped with the appropriate gas handling system. This often includes automated flow control, safety interlocks, and potentially gas leak detection systems to ensure both process integrity and facility safety.

Making the Right Choice for Your Application

To ensure safety, you must align the furnace's features with the specific demands of your work.

- If your primary focus is general-purpose heat treatment: Ensure the furnace has the core features: a door interlock, Over-Temperature Protection, and double-shell construction for a low external temperature.

- If your primary focus is processing materials with binders or volatiles: You must select a furnace with, or plan to integrate, a proper exhaust system or fume hood to safely vent all byproducts.

- If your primary focus is high-precision, unattended operation: Prioritize a furnace with an advanced, programmable digital controller that offers real-time monitoring and configurable alarms.

Ultimately, a safe laboratory environment is built on a foundation of well-designed equipment and well-informed operators.

Summary Table:

| Safety Feature | Description | Key Benefit |

|---|---|---|

| Double-Shell Construction | Air gap and insulation between inner and outer shells | Low external surface temperatures (<60°C) for burn prevention |

| Positive-Break Door Switch | Cuts power when door is opened | Prevents exposure to heat and electrical hazards |

| Over-Temperature Protection (OTP) | Redundant controller that cuts power if limits are exceeded | Avoids thermal runaway and equipment damage |

| Emergency Shut-Off Button | Immediate power cut in emergencies | Failsafe stop for all operations |

| Programmable Controls | Digital controllers for heating/cooling rates | Ensures process repeatability and prevents thermal shocks |

| Fume Hoods and Exhaust Systems | Optional for venting hazardous byproducts | Safely manages volatile materials and fumes |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, integrating essential safety features for peace of mind. Contact us today to discuss how we can enhance your processes and protect your operations!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety