In essence, a muffle furnace is a high-temperature oven used for general-purpose material processing where sample purity is critical. Its most common uses include ashing to determine the non-combustible content of a sample, heat-treating metals and ceramics to alter their properties, and performing chemical analyses like loss on ignition.

The core value of a muffle furnace lies in its insulated inner chamber—the "muffle"—which isolates a sample from direct heating elements and combustion byproducts. This ensures precise, uniform heating in a contamination-free environment, making it the ideal tool for processes where material purity and consistency are paramount.

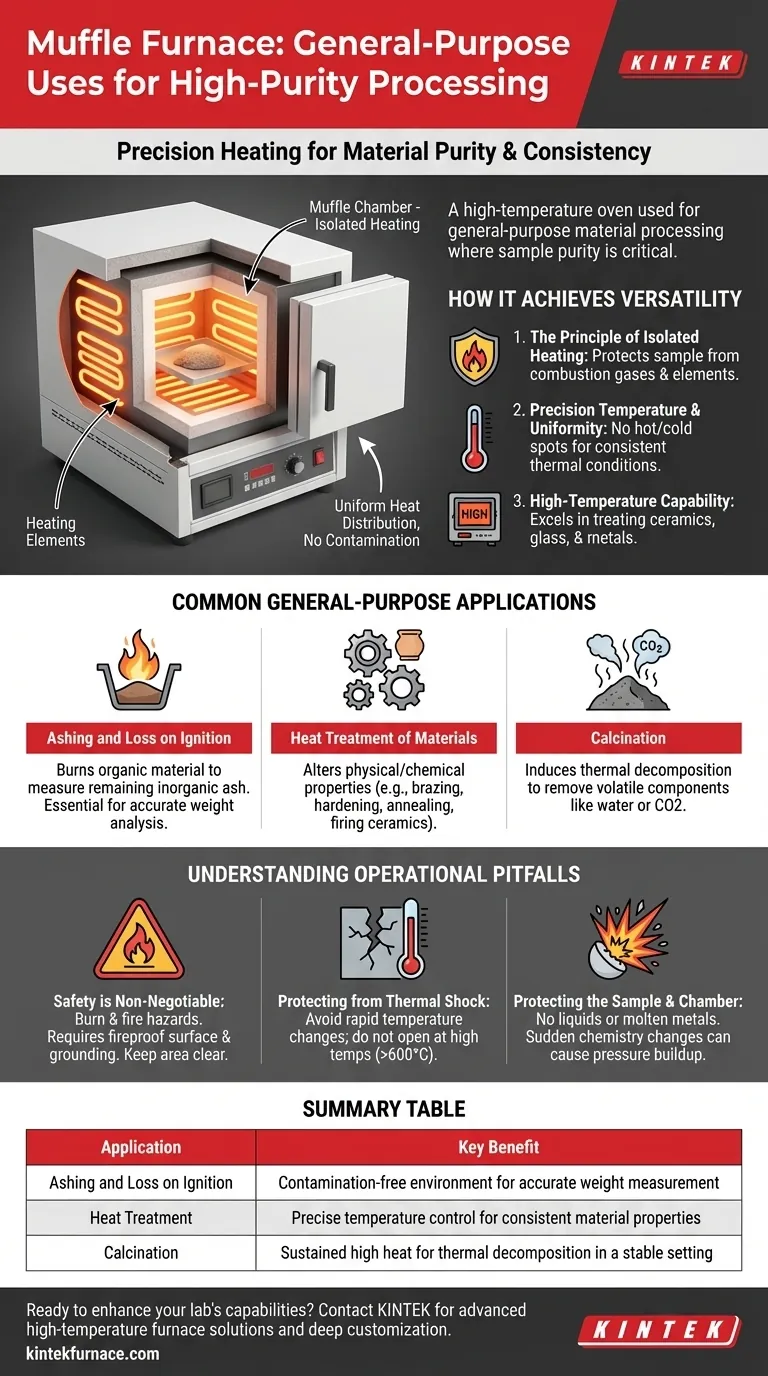

How a Muffle Furnace Achieves Versatility

The furnace's design is not just about getting hot; it's about creating a highly controlled environment. This control is what makes it a versatile laboratory and industrial workhorse.

The Principle of Isolated Heating

Historically, the term "muffle" referred to a chamber that shielded a material from the flames and soot of a fuel-based fire. Today's electric furnaces maintain this core principle.

The muffle chamber is an insulated interior that contains the heat and protects the material inside. This separation prevents the sample from being contaminated by combustion gases or direct contact with the heating elements.

This design is crucial for processes like ashing or sintering, where maintaining the chemical integrity of the sample is the primary goal.

Precision Temperature and Uniformity

The insulated chamber allows for exceptionally precise temperature control and uniform heat distribution.

Because the heat radiates evenly throughout the sealed chamber, there are no hot or cold spots. This ensures the entire sample is processed under the exact same thermal conditions.

High-Temperature Capability

Muffle furnaces are specifically designed for high-temperature material processing, often reaching temperatures quickly and holding them for extended periods.

They are not suitable for low-temperature applications but excel at treating ceramics, glass, and metals, as well as the thermal destruction of organic materials.

Common General-Purpose Applications

While specialized furnaces exist, the muffle furnace handles a broad range of fundamental high-temperature tasks.

Ashing and Loss on Ignition

Ashing is a process that burns away all organic material in a sample to measure the weight of the remaining non-combustible inorganic material (ash).

A muffle furnace provides the contained, high-heat environment necessary for complete combustion without introducing contaminants that would alter the final weight. Loss on ignition (LOI) is a similar analysis that measures the weight lost from a sample after heating.

Heat Treatment of Materials

This is a broad category of processes that use heat to alter a material's physical and sometimes chemical properties.

Applications include brazing, hardening, or annealing metals, as well as firing ceramics. The furnace's uniform heat ensures predictable and consistent results.

Calcination

Calcination involves heating a solid material to a high temperature to induce thermal decomposition, typically to remove a volatile component like water or carbon dioxide.

The furnace's ability to apply sustained, controlled heat in a stable environment makes it ideal for these types of chemical transformations.

Understanding the Operational Pitfalls

The power of a muffle furnace comes with strict operational requirements. Misuse can damage the equipment, ruin the sample, and create significant safety hazards.

Safety Is Non-Negotiable

A muffle furnace presents serious burn and fire hazards. It must be placed on a stable, fireproof surface with proper electrical grounding.

The surrounding area must be completely free of flammable or explosive substances.

Protecting the Furnace from Thermal Shock

The refractory materials that insulate the furnace are vulnerable to thermal shock—damage caused by rapid temperature changes.

Never open the furnace door at extremely high temperatures (e.g., above 600°C). After a cycle, allow the furnace to cool slowly before removing samples.

Protecting the Sample and Chamber

Never place liquids or attempt to pour molten metals into the furnace chamber. It is designed for processing solids in a controlled state.

Sudden changes in sample chemistry can lead to pressure buildup inside the sealed chamber, creating a risk of accidents. Samples must be handled carefully with appropriate tongs and protective gear.

Making the Right Choice for Your Goal

To leverage a muffle furnace effectively, align its capabilities with the primary goal of your process.

- If your primary focus is quantitative analysis (ashing, LOI): The furnace's most critical feature is its contamination-free environment, ensuring the final sample weight is accurate.

- If your primary focus is material modification (heat treating, firing ceramics): The precise temperature control and uniform heat distribution are essential for achieving consistent and predictable material properties.

- If your primary focus is chemical decomposition (calcination): The furnace's core value is its ability to apply sustained, high heat in a stable, contained environment.

By understanding its core principle of isolated heating, you can effectively apply the muffle furnace to a wide range of high-purity, high-temperature processes.

Summary Table:

| Application | Key Benefit |

|---|---|

| Ashing and Loss on Ignition | Contamination-free environment for accurate weight measurement |

| Heat Treatment | Precise temperature control for consistent material properties |

| Calcination | Sustained high heat for thermal decomposition in a stable setting |

Ready to enhance your lab's capabilities with a reliable muffle furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how our tailored solutions can optimize your material processing for superior purity and performance!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis