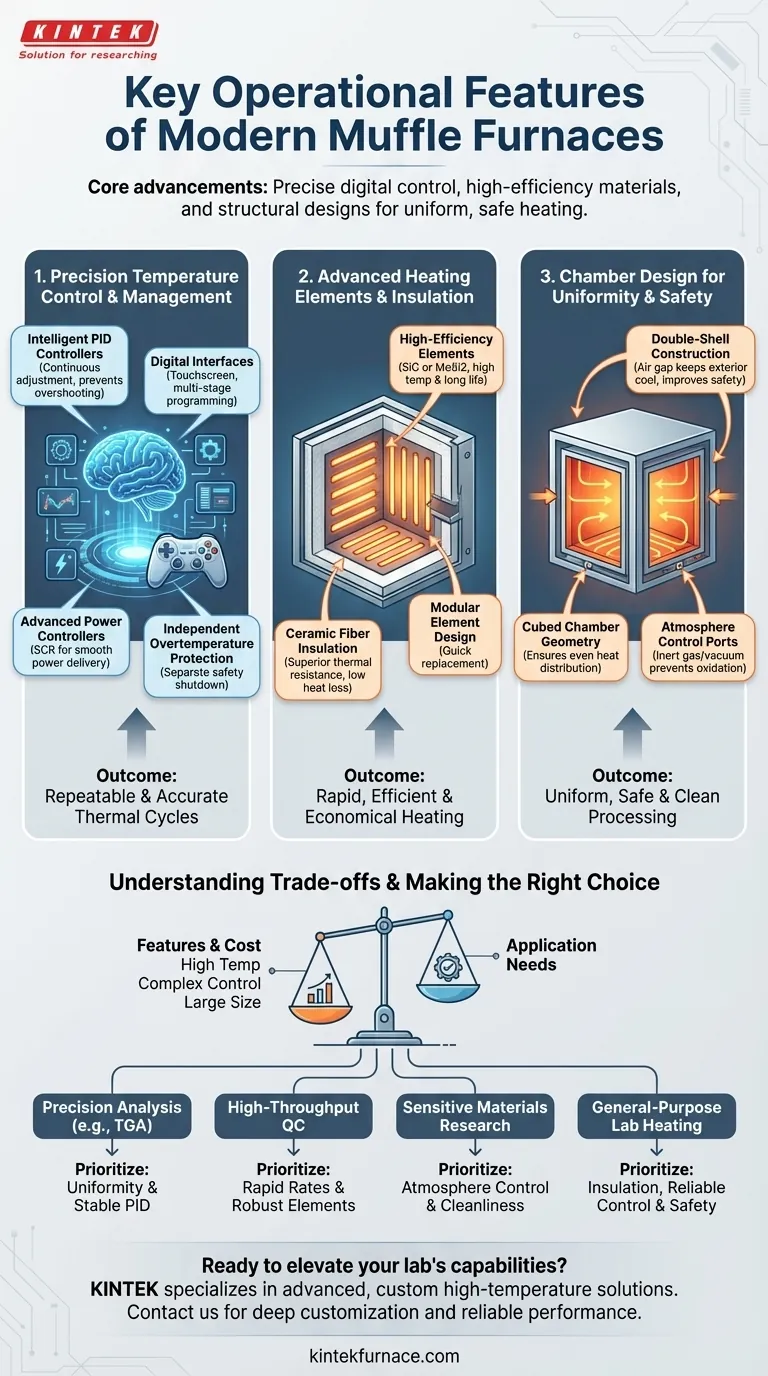

In essence, modern muffle furnaces are defined by three core operational advancements: precise digital temperature control, high-efficiency materials for rapid and economical heating, and structural designs that ensure uniform heat distribution and operator safety. These features work in concert to deliver repeatable, accurate, and clean high-temperature processing.

The key evolution is the shift from a simple heated box to an intelligent thermal processing system. The focus is no longer just on reaching a high temperature, but on controlling the entire thermal cycle—from heating rate to atmosphere—with absolute precision and efficiency.

The Pillars of Modern Furnace Operation

To understand the value of a modern furnace, you must look beyond its maximum temperature. The most critical features are those that guarantee control, efficiency, and consistency for your specific application.

Precision Temperature Control and Management

The brain of the furnace is its control system. This is where the most significant gains in accuracy and repeatability have been made.

- Intelligent PID Controllers: Proportional-Integral-Derivative (PID) controllers are standard. They continuously monitor temperature and intelligently adjust power to prevent overshooting the setpoint, ensuring exceptional stability.

- Digital Interfaces: Touchscreen or digital displays allow for precise input of temperature and time. Many support multi-stage programming, enabling complex heating, soaking, and cooling cycles automatically.

- Advanced Power Controllers: Phase angle-fire SCR (Silicon Controlled Rectifier) power controllers finely modulate the energy sent to the heating elements, providing smooth and highly responsive power delivery.

- Independent Overtemperature Protection: This crucial safety feature uses a separate controller and thermocouple to shut the furnace down if it exceeds a safe temperature limit, protecting both the furnace and its contents.

Advanced Heating Elements and Insulation

The performance and efficiency of a furnace are dictated by the materials used in its construction. Modern furnaces leverage specialized materials to reduce energy consumption and improve heating speed.

- High-Efficiency Heating Elements: While older furnaces used simple resistance coils, modern units often employ silicon carbide (SiC) or molybdenum disilicide (MoSi2) elements. These provide stable heating to very high temperatures with greater energy efficiency and a longer service life.

- Ceramic Fiber Insulation: Lightweight, high-purity alumina or ceramic fiber insulation offers superior thermal resistance compared to traditional brick. This significantly reduces heat loss, lowers energy costs, and allows the furnace's exterior to remain cooler.

- Modular Element Design: Many premium furnaces feature modular heating elements. This design simplifies maintenance, allowing a single failed element to be replaced quickly without dismantling the entire heating system.

Chamber Design for Uniformity and Safety

The physical structure of the furnace is engineered to ensure even heating and safe operation.

- Double-Shell Construction: An inner and outer casing with an air gap between them is a hallmark of quality design. This feature minimizes heat transfer to the exterior shell, keeping it safe to the touch and improving overall energy efficiency.

- Cubed Chamber Geometry: A chamber with dimensions that are roughly equal in height, width, and depth provides the most uniform heat distribution. This is critical for applications where every part of the sample must experience the exact same temperature.

- Atmosphere Control: Many furnaces now offer ports for introducing controlled atmospheres, such as nitrogen or argon, to prevent oxidation. Some even offer vacuum capabilities for highly sensitive processes.

Understanding the Trade-offs

Selecting a furnace involves balancing features against cost and intended use. Not every application requires the most advanced and expensive option.

Heating Elements vs. Temperature Needs

The type of heating element directly impacts the furnace's maximum temperature and cost. MoSi2 elements can reach very high temperatures (e.g., 1800°C) but are costly. For many applications below 1400°C, SiC elements provide an excellent balance of performance and value.

Control Sophistication vs. Application

A furnace with a multi-stage programmable PID controller is essential for complex metallurgical or research protocols. However, for straightforward tasks like ashing or drying, a simpler single-setpoint digital controller is often sufficient, reliable, and more cost-effective.

Chamber Size vs. Uniformity

While a larger chamber offers more capacity, maintaining perfect temperature uniformity becomes more challenging and energy-intensive. For applications demanding the highest precision, a correctly sized, cubed chamber will consistently outperform a larger, partially filled one.

Making the Right Choice for Your Goal

The "best" furnace is the one whose features align directly with your operational requirements.

- If your primary focus is precision analysis (e.g., TGA, environmental testing): Prioritize exceptional temperature uniformity (cubed chamber) and a highly stable PID controller.

- If your primary focus is high-throughput quality control: Look for rapid heating/cooling rates and robust, modular heating elements for minimal downtime.

- If your primary focus is research on sensitive materials: Atmosphere control capabilities (inert gas or vacuum) and contamination-free electric operation are non-negotiable.

- If your primary focus is general-purpose lab heating: A well-insulated unit with a reliable digital controller and robust safety features will deliver the best long-term value.

Ultimately, understanding these operational features empowers you to select a tool that is not just a heat source, but a precise instrument for achieving your goals.

Summary Table:

| Feature Category | Key Components | Benefits |

|---|---|---|

| Temperature Control | PID Controllers, Digital Interfaces, SCR Power Controllers | Precise and repeatable thermal cycles, enhanced safety |

| Heating Elements & Insulation | SiC/MoSi2 Elements, Ceramic Fiber Insulation | High efficiency, rapid heating, energy savings |

| Chamber Design | Double-Shell Construction, Cubed Geometry, Atmosphere Control | Uniform heat distribution, operator safety, contamination prevention |

Ready to elevate your lab's capabilities with a custom high-temperature furnace? KINTEK specializes in advanced solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Leveraging our strong R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs—ensuring precision, efficiency, and reliability. Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites