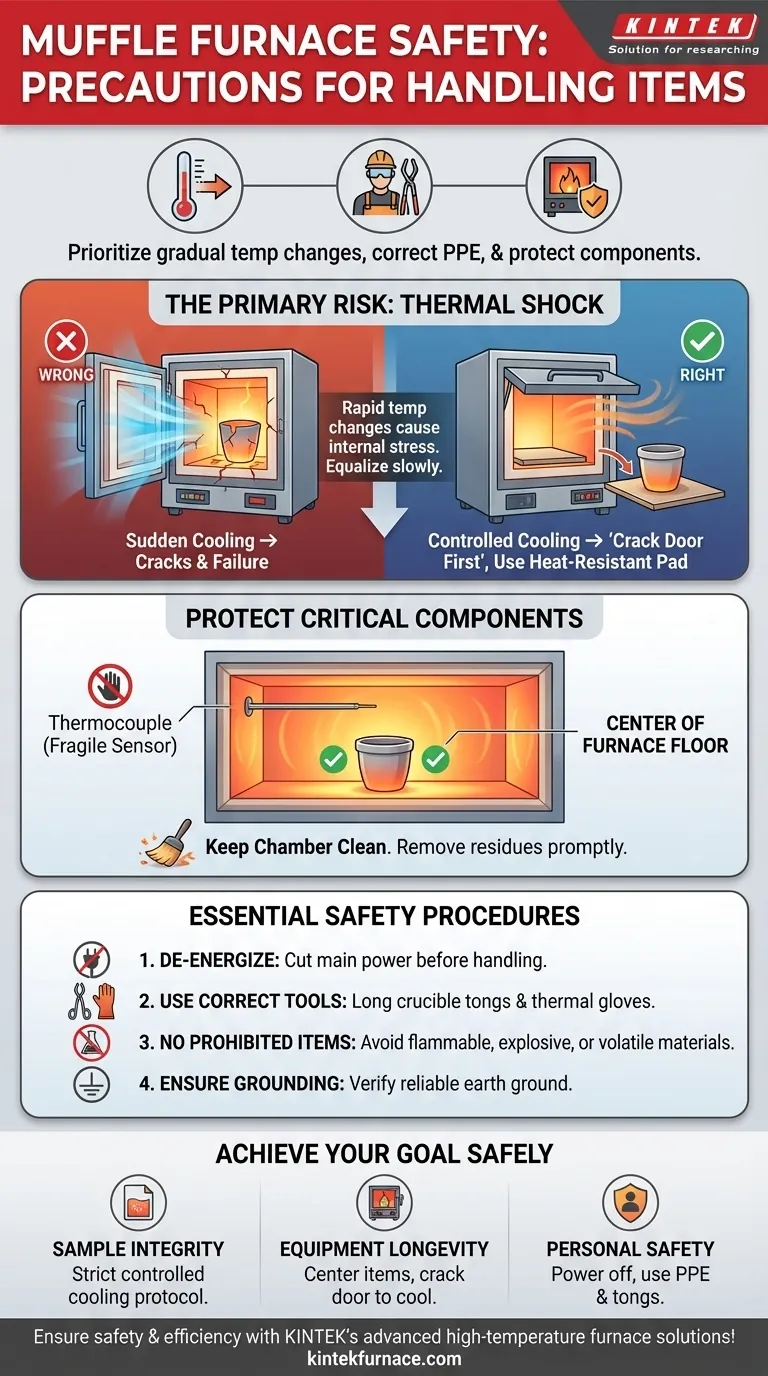

To handle items safely in a muffle furnace, you must prioritize gradual temperature changes, use the correct personal protective equipment (PPE), and protect the furnace's sensitive components. The most critical actions involve using long crucible tongs for all handling, carefully avoiding contact with the internal thermocouple, and implementing a controlled cooling process before fully opening the furnace door to prevent thermal shock.

The greatest risks in muffle furnace operation are not just personal burns, but catastrophic damage to the furnace lining and critical sensors from thermal shock. Safe handling is therefore a discipline of managing extreme temperature gradients, not just moving an object from one place to another.

The Principle of Thermal Shock: Your Primary Concern

Thermal shock occurs when a material experiences a rapid, drastic change in temperature, causing internal stresses that can lead to cracking and failure. This is the single most important principle to understand for furnace safety and longevity.

What Causes Thermal Shock?

When cold air rushes into a hot furnace, it causes the surface of the ceramic lining and your crucible to contract much faster than their core. This differential contraction creates immense stress.

Think of it like pouring cold water into a hot glass dish—the same principle applies, but at a much more extreme and destructive scale.

Preventing Damage to the Furnace Chamber

The most common cause of furnace damage is opening the door too quickly after a high-temperature cycle. This sudden influx of cool air can crack the fragile ceramic insulation inside.

To prevent this, always cut the power and let the furnace cool significantly. Then, open the door just a small slit first. This allows temperature and pressure to equalize gradually before you open the door fully.

Protecting Your Crucibles and Samples

The same forces that damage the furnace can destroy your work. A crucible removed from a 1000°C furnace and placed on a cool lab bench can easily fracture, ruining your sample.

Always use tongs to move hot items to a designated, heat-resistant cooling area, allowing them to return to ambient temperature slowly.

Protecting Critical Furnace Components

Beyond thermal shock, safe operation requires a conscious effort to protect the furnace's internal hardware. Mishandling items can lead to immediate and costly damage.

The Fragility of the Thermocouple

The thermocouple is the temperature sensor, a thin probe extending into the furnace chamber. When hot, it is extremely fragile and can be broken with even a slight touch from a crucible or rack.

Always be aware of the thermocouple's location when placing or removing items. Place your items neatly in the center of the furnace floor, well away from the walls and the sensor.

Maintaining a Clean Furnace Interior

Over time, oxides and other residues can build up on the furnace floor. This debris can corrode the heating elements and the furnace lining.

Keep the furnace chamber clean and promptly remove any spills or residues after the furnace has cooled completely. This extends the life of the heating elements and ensures more uniform heating.

Common Pitfalls and Procedural Safeguards

Following a strict procedure is non-negotiable for safety. These rules are designed to protect both the operator and the equipment from predictable, and preventable, failures.

Always De-energize the Furnace

Before loading or retrieving samples, cut the main power supply to the furnace. This is a fundamental electrical safety step that eliminates the risk of shock. An additional, clearly marked master switch near the furnace is highly recommended.

Using the Right Tools and PPE

Never handle items, hot or cold, with your hands. Always use long crucible tongs to maintain a safe distance and provide a secure grip.

Wear thermal-resistant gloves and appropriate eye protection to shield yourself from intense radiant heat and potential burns, even when just opening the door briefly.

Handling Prohibited Materials

Never place flammable, explosive, or volatile materials inside a muffle furnace. The extreme heat can lead to uncontrolled reactions or explosions.

Similarly, avoid placing samples containing significant amounts of liquids or oils, as they can vaporize, create a hazardous atmosphere, and damage the furnace interior.

Ensuring Electrical and Environmental Grounding

The furnace and its controller must be reliably grounded to a proper earth ground. This is your primary defense against electric shock in the event of an electrical fault.

Operate the furnace on a dedicated circuit with its own power control to avoid overloading electrical systems.

Making the Right Choice for Your Goal

Your specific procedure is a balance of protecting your sample, the equipment, and yourself. All three are interconnected.

- If your primary focus is sample integrity: Adhere strictly to a slow, controlled cooling protocol to prevent your material from cracking due to thermal shock.

- If your primary focus is equipment longevity: Make it a habit to always place items in the center of the furnace, far from the delicate thermocouple, and to cool the chamber gradually by cracking the door first.

- If your primary focus is personal safety: Always cut the power before handling items, wear thermal gloves, and use long crucible tongs to maintain a safe distance from the heat.

By mastering these fundamental precautions, you ensure safe, repeatable, and effective results from your work.

Summary Table:

| Precaution | Key Action | Purpose |

|---|---|---|

| Prevent Thermal Shock | Open door gradually after cooling; use controlled cooling for items | Avoid cracking furnace lining and samples |

| Use Correct PPE | Wear thermal gloves and eye protection; use long crucible tongs | Protect against burns and ensure safe handling |

| Protect Components | Place items away from thermocouple; keep furnace interior clean | Prevent damage to sensors and heating elements |

| De-energize Furnace | Cut power before loading or retrieving samples | Eliminate electrical shock risks |

| Avoid Prohibited Materials | Do not use flammable or volatile substances | Prevent explosions and furnace damage |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental requirements, enhancing performance and longevity. Contact us today to discuss how we can support your specific needs and deliver tailored solutions for optimal results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency