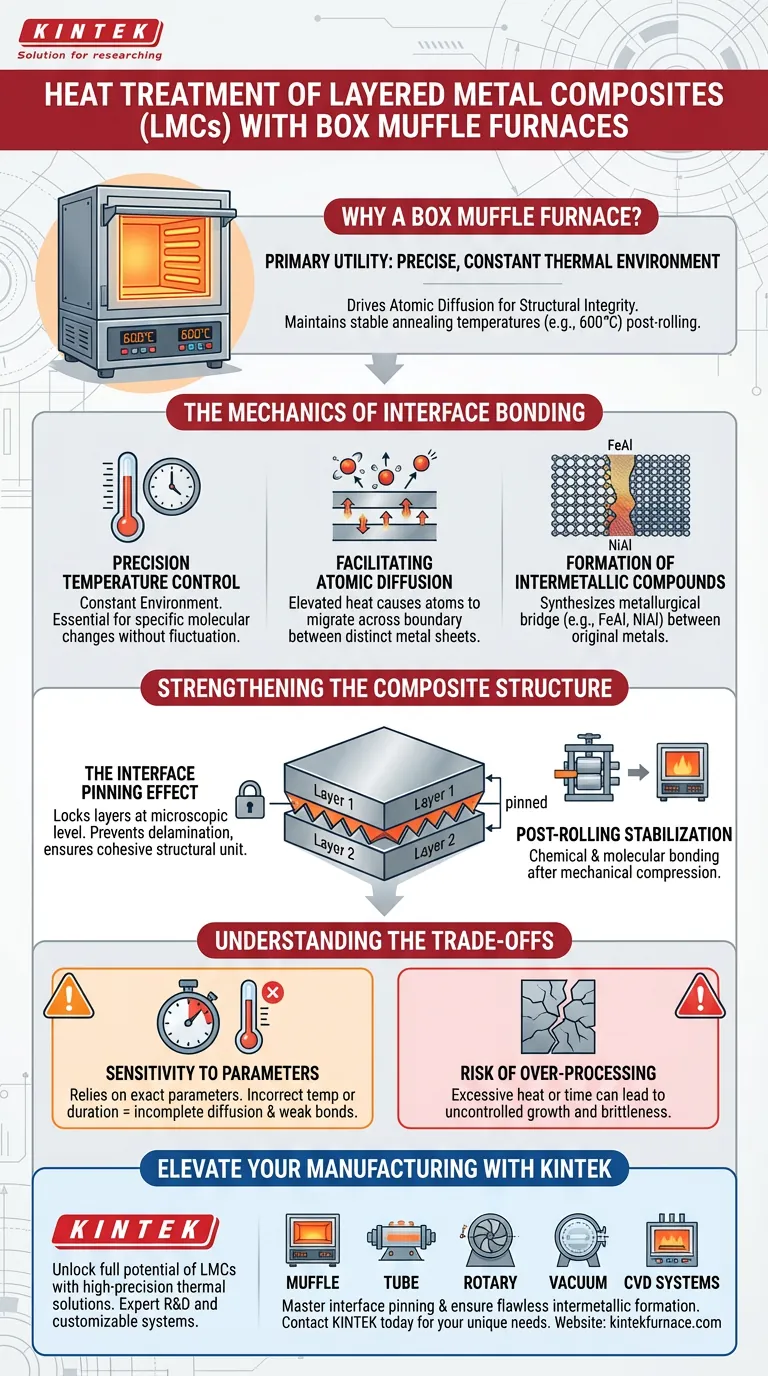

The primary utility of a box muffle furnace in the processing of Layered Metal Composites (LMCs) is to create a precise, constant thermal environment that drives atomic diffusion. By maintaining stable annealing temperatures—typically around 600°C—after the rolling process, the furnace enables the formation of critical intermetallic compound layers that are essential for structural integrity.

By facilitating controlled atomic diffusion, the box muffle furnace promotes the "interface pinning effect." This mechanism transforms weak boundaries into robust mechanical bonds through the synthesis of compounds like FeAl or NiAl.

The Mechanics of Interface Bonding

Precision Temperature Control

The fundamental requirement for treating LMCs is a constant temperature environment. A box muffle furnace provides the stability necessary to hold materials at exact specifications, such as 600°C, without significant fluctuation. This consistency is vital for initiating specific molecular changes across the entire workpiece.

Facilitating Atomic Diffusion

At these elevated temperatures, the furnace facilitates atomic diffusion at the interface between the metal layers. The heat energy excites atoms, causing them to migrate across the boundary separating the distinct metal sheets. This movement is the precursor to creating a unified composite rather than just two sheets pressed together.

Formation of Intermetallic Compounds

The goal of this diffusion is the creation of intermetallic compound layers. Depending on the materials used, compounds such as Iron-Aluminum (FeAl) or Nickel-Aluminum (NiAl) are synthesized. These new layers act as a metallurgical bridge between the original constituent metals.

Strengthening the Composite Structure

The Interface Pinning Effect

The formation of these intermetallic layers triggers the interface pinning effect. This phenomenon effectively locks the layers together at a microscopic level. It prevents delamination and ensures the composite behaves as a single, cohesive structural unit.

Post-Rolling Stabilization

This heat treatment is specifically utilized after the rolling process. While rolling mechanically compresses the layers, the furnace treatment provides the chemical and molecular bonding required for true interlaminar strength.

Understanding the Trade-offs

Sensitivity to Duration and Temperature

While the furnace enables strengthening, the process relies heavily on exact parameters. If the temperature deviates from the target (e.g., 600°C) or the duration is incorrect, the diffusion process may remain incomplete, leading to weak bonds.

Risk of Over-Processing

Conversely, excessive heat or time can alter the material structure unpredictably. The formation of intermetallic compounds must be controlled; uncontrolled growth can sometimes lead to brittleness rather than strength. The muffle furnace is a tool of precision, and its effectiveness is entirely dependent on the operator's adherence to the specific recipe required for the alloy.

Optimizing Your Heat Treatment Process

To maximize the performance of your Layered Metal Composites, consider your specific structural goals:

- If your primary focus is Bonding Strength: Ensure your furnace is calibrated to maintain the exact temperature required (e.g., 600°C) to maximize atomic diffusion and the interface pinning effect.

- If your primary focus is Material Consistency: Utilize the constant temperature capabilities of the box muffle furnace to ensure uniform intermetallic compound formation across the entire surface area.

Success in LMC fabrication ultimately relies on leveraging the furnace's stability to precisely engineer the molecular interface between metal layers.

Summary Table:

| Feature | Role in LMC Heat Treatment | Outcome |

|---|---|---|

| Temperature Stability | Maintains constant heat (e.g., 600°C) | Ensures uniform atomic diffusion |

| Atomic Diffusion | Facilitates molecular migration across layers | Precursor to metallurgical bonding |

| Compound Synthesis | Forms intermetallic layers (FeAl, NiAl) | Creates a robust chemical bridge |

| Interface Pinning | Locks layers at a microscopic level | Prevents delamination and increases strength |

Elevate Your Composite Manufacturing with KINTEK

Unlock the full potential of your Layered Metal Composites with KINTEK’s high-precision thermal solutions. Backed by expert R&D and manufacturing, we offer industry-leading Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific annealing and diffusion requirements.

Whether you need to master the interface pinning effect or ensure flawless intermetallic compound formation, our lab high-temp furnaces provide the thermal stability essential for your success. Contact KINTEK today to discuss your unique needs and let our experts help you engineer the perfect thermal environment for your materials.

Visual Guide

References

- The Influence of Interface Morphology on the Mechanical Properties of Binary Laminated Metal Composites Fabricated by Hierarchical Roll-Bonding. DOI: 10.3390/met15060580

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the main applications of a muffle furnace? Unlock Precision Heating for Material Transformations

- What materials are used in the construction of muffle furnaces to ensure durability? Discover the Key Components for Long-Lasting Performance

- What is the specific role of a box muffle furnace in the austenitizing of Vanadis 60? Achieve Precise Hardening Control

- What is the working principle of the box furnace's door mechanism? Ensure Safety and Efficiency in Your Lab

- How does an industrial-grade box-type high-temperature furnace contribute to the formation of the NaY(WO4)2 crystal phase?

- What materials are used in the construction of the muffle furnace? Discover the Key Components for High-Temp Performance

- Why are box type electric furnaces indispensable in industry and laboratories? Unlock Precision and Versatility in Thermal Processing

- What safety measures should be observed around the muffle furnace? Essential Protocols for Safe Operation