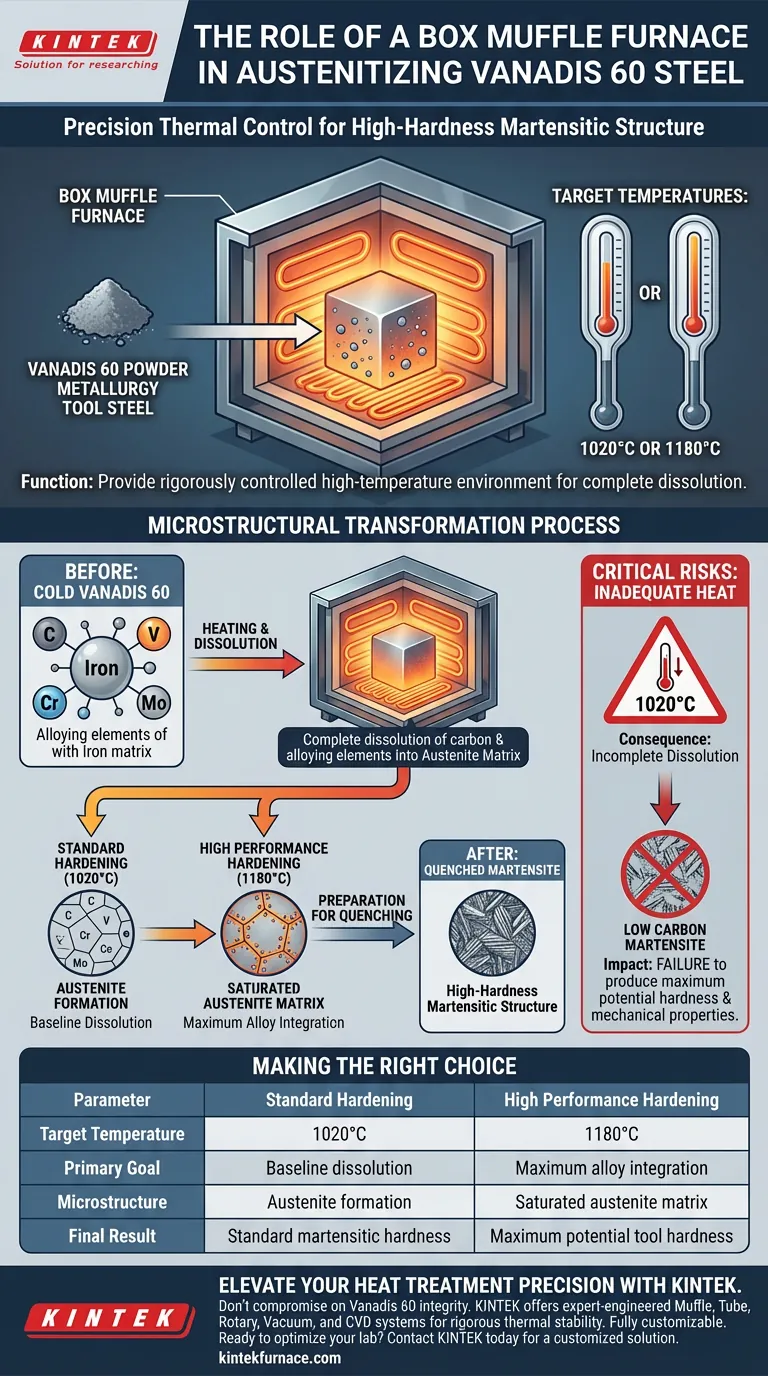

The specific role of a box muffle furnace in this process is to provide a rigorously controlled high-temperature environment essential for austenitizing Vanadis 60 powder metallurgy tool steel. By maintaining precise temperatures, typically at 1020°C or 1180°C, the furnace facilitates the complete dissolution of chemical components required for the steel's final hardening.

The furnace’s ability to maintain exacting heat levels ensures the complete dissolution of alloying elements and carbon into the austenite matrix. This step is the foundational requirement for developing a high-hardness martensitic structure during the subsequent quenching phase.

The Function of Precise Thermal Control

Establishing Critical Temperatures

The primary function of the box muffle furnace is to reach and stabilize specific austenitizing temperatures. For Vanadis 60, the process targets two distinct thermal set points: 1020°C or 1180°C.

Ensuring Environmental Stability

The "box muffle" design isolates the workload, creating a strictly controlled environment. This isolation is necessary to maintain the thermal uniformity required across the entire cross-section of the steel component.

Driving Microstructural Transformation

Dissolution of Elements

At these elevated temperatures, the furnace facilitates a critical chemical reaction. It drives the complete dissolution of carbon and alloying elements into the steel's austenite matrix.

Creating the Austenite Matrix

This dissolution transforms the internal structure of the steel into austenite. This phase is unstable at room temperature but is the necessary precursor for the final hardening steps.

Preparation for Quenching

The furnace prepares the steel for the quenching phase. Without the thorough homogenization achieved in the furnace, the steel cannot form the high-hardness martensitic structure required for tool performance.

Understanding the Critical Risks

Consequences of Inadequate Heat

If the furnace fails to maintain the strict temperature floor (e.g., dropping below the 1020°C threshold), dissolution will be incomplete. This results in a matrix that lacks the necessary carbon content.

Impact on Final Hardness

A failure in the furnace's control leads directly to a failure in mechanical properties. If the alloying elements do not fully dissolve into the austenite, the subsequent quenching will fail to produce the maximum potential hardness.

Making the Right Choice for Your Goal

To maximize the performance of Vanadis 60 tool steel, you must align the furnace settings with your specific material requirements.

- If your primary focus is standard austenitizing: Ensure the furnace is calibrated to maintain a stable 1020°C to achieve baseline dissolution.

- If your primary focus is maximum alloy solution: Utilize the higher setting of 1180°C to drive the most complete integration of elements for the hardest possible martensitic structure.

The precision of your furnace temperature directly dictates the integrity of the final martensitic microstructure.

Summary Table:

| Parameter | Standard Hardening | High Performance Hardening |

|---|---|---|

| Target Temperature | 1020°C | 1180°C |

| Primary Goal | Baseline dissolution | Maximum alloy integration |

| Microstructure | Austenite formation | Saturated austenite matrix |

| Final Result | Standard martensitic hardness | Maximum potential tool hardness |

Elevate Your Heat Treatment Precision with KINTEK

Don’t compromise on the integrity of your Vanadis 60 tool steel. Achieving the perfect martensitic structure requires the rigorous thermal stability that only expert-engineered equipment can provide.

KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all backed by world-class R&D and manufacturing. Our high-temperature lab furnaces are fully customizable to meet your specific metallurgy requirements, ensuring your components reach maximum hardness and durability every time.

Ready to optimize your lab's performance? Contact KINTEK today for a customized solution

Visual Guide

References

- Florentino Álvarez-Antolín, Alejandro González-Pociño. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Vanadis 60 Steel: A Statistical Design Approach. DOI: 10.3390/solids6030046

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-temperature muffle furnace play in KNN-based ceramic powder pre-sintering? Key Synthesis Insights

- What is the role of a laboratory box muffle furnace in the compositional analysis of finger millet popcorn?

- What role does a muffle furnace play in the curing process of GaN and TiO2? Optimize Your Photoanode Sintering

- How does the temperature range affect the choice of a muffle furnace? Ensure Precision and Protect Your Materials

- How should samples be placed inside the muffle furnace? Ensure Uniform Heating and Safety

- What role do box type electric furnaces play in metal melting? Ideal for Small-Scale Lab and Prototyping Needs

- What materials are sintering furnaces best suited for? Optimize Your Powder Processing with the Right Furnace

- What role do muffle furnaces play in advanced materials research? Essential for Precise Thermal Processing