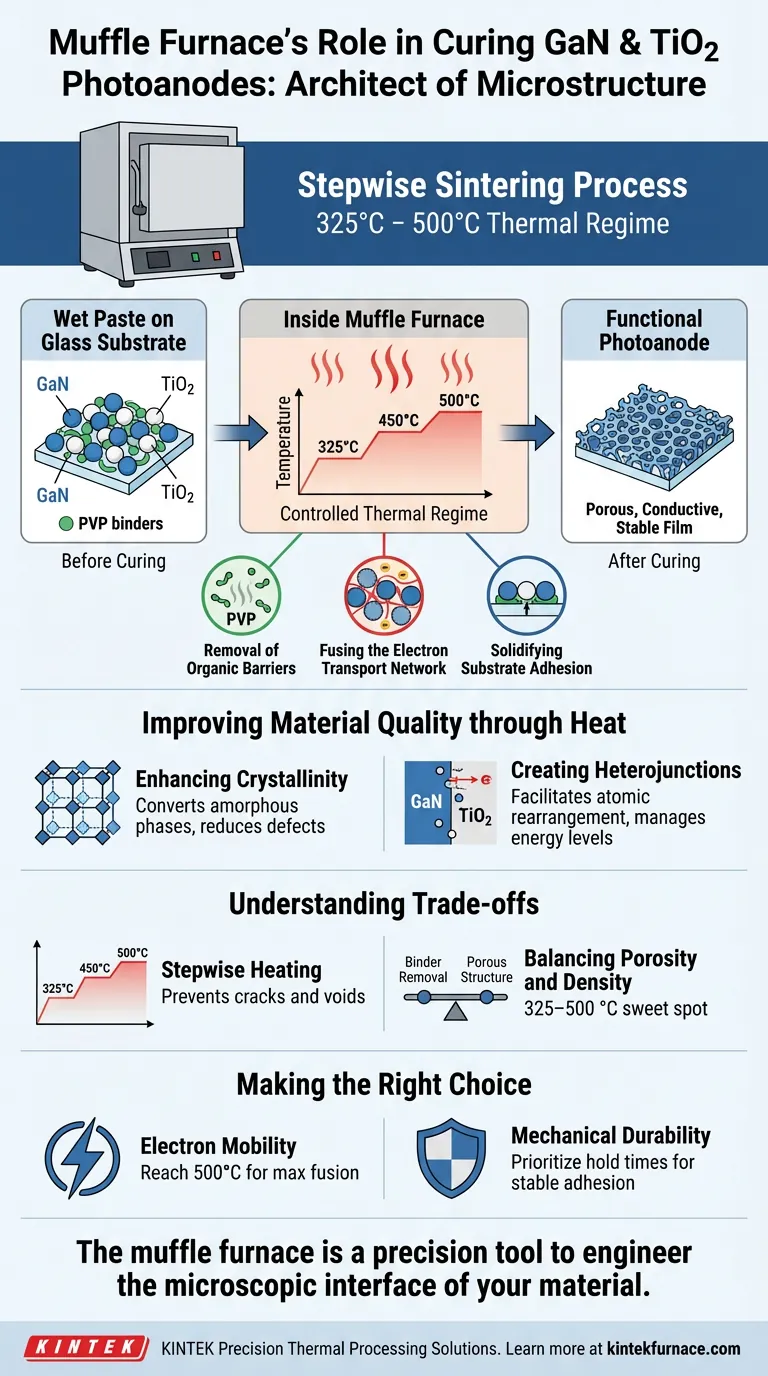

The muffle furnace acts as the architect of the electrode's microstructure, primarily responsible for executing a precise stepwise sintering process. It subjects the GaN and TiO2 composite paste to a controlled thermal regime ranging from 325 °C to 500 °C, which is necessary to convert the raw chemical mixture into a functional photoanode on the glass substrate.

The muffle furnace transforms a wet paste into a high-performance semiconductor film by burning off organic insulators and physically fusing nanoparticles. This process creates the continuous conductive network required for efficient electron transport.

Transforming Paste into a Functional Electrode

The curing process is not merely about drying; it is about fundamentally altering the chemistry and physics of the coated film. The muffle furnace facilitates three critical changes during sintering.

Removal of Organic Barriers

The composite paste contains organic solvents and binders, specifically Polyvinylpyrrolidone (PVP), which help apply the paste but inhibit electricity.

The muffle furnace heats the material to temperatures where these organics decompose and vaporize. This "cleaning" process removes insulating barriers, ensuring that nothing separates the semiconductor particles from one another.

Fusing the Electron Transport Network

Once the binders are removed, the remaining Gallium Nitride (GaN) and Titanium Dioxide (TiO2) nanoparticles must form a cohesive unit.

The high heat (up to 500 °C) causes the nanoparticles to fuse together, creating a porous network. This interconnected structure allows for high electron transport efficiency, ensuring that charge carriers generated by light can move freely through the film.

Solidifying Substrate Adhesion

A photoanode is useless if the active material peels off the conductive glass.

The thermal energy provided by the furnace facilitates strong physical adhesion between the composite film and the glass substrate. This ensures the mechanical stability of the device and improves the electrical contact at the interface.

Improving Material Quality through Heat

Beyond the primary sintering mechanics, the thermal environment of the muffle furnace enhances the intrinsic properties of the materials.

Enhancing Crystallinity

While the primary goal is fusion, the heat treatment also improves the crystalline structure of the TiO2.

By converting amorphous or low-crystalline components into stable phases, the furnace reduces defects in the material. A higher degree of crystallinity translates directly to better stability and superior photo-activity.

Creating Heterojunctions

The interaction between GaN and TiO2 relies on a precise interface to manage energy levels.

The thermal energy facilitates atomic rearrangement at the points where the two materials meet. This helps construct a functional heterojunction, which is critical for separating and directing the electrical charges generated by the photoanode.

Understanding the Trade-offs

The Importance of Stepwise Heating

The process must be stepwise, not instantaneous.

Ramping the temperature too quickly can trap evaporating solvents or organic gases inside the film, leading to cracks or voids. A controlled ramp (e.g., 325 °C to 500 °C) allows for the gradual release of byproducts, preserving the structural integrity of the porous network.

Balancing Porosity and Density

The furnace temperature dictates the final morphology of the film.

Insufficient heat may leave residual binders (low conductivity), while excessive heat could collapse the porous structure entirely (reducing surface area). The specific 325–500 °C range is the "sweet spot" that balances binder removal with the preservation of the porous surface area needed for chemical reactions.

Making the Right Choice for Your Goal

To maximize the performance of your GaN/TiO2 photoanodes, you must align your furnace protocol with your specific performance metrics.

- If your primary focus is Electron Mobility: Ensure your profile reaches the upper limit (500 °C) to guarantee the complete removal of PVP binders and maximize nanoparticle fusion.

- If your primary focus is Mechanical Durability: Prioritize the duration of the hold times during the stepwise ramp to allow the film to settle and adhere to the glass without thermal shock.

Success depends on using the muffle furnace not just as a heater, but as a precision tool to engineer the microscopic interface of your material.

Summary Table:

| Process Phase | Temperature Range | Key Function & Material Impact |

|---|---|---|

| Organic Removal | 325 °C - 450 °C | Decomposes PVP binders & solvents to remove insulating barriers. |

| Nanoparticle Fusion | Up to 500 °C | Fuses GaN and TiO2 particles into a porous, conductive network. |

| Substrate Adhesion | Sustained High Heat | Ensures mechanical stability & electrical contact with glass substrate. |

| Crystallinity Optimization | 450 °C - 500 °C | Reduces defects and forms functional heterojunctions for charge separation. |

Elevate Your Material Research with KINTEK Precision

Precision thermal processing is the difference between a failing film and a high-performance semiconductor. KINTEK provides industry-leading muffle, tube, and vacuum systems designed specifically for the delicate stepwise sintering required for GaN and TiO2 composite materials.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems offer the thermal stability needed to prevent cracks and optimize porosity.

- Customizable Solutions: Whether you need a standard Muffle furnace or specialized CVD/Rotary systems, we tailor our tech to your lab's unique requirements.

- Targeted Performance: Achieve superior electron mobility and mechanical durability with our advanced temperature control interfaces.

Ready to refine your photoanode production? Contact us today to find your perfect furnace solution!

Visual Guide

References

- Olzat Toktarbaiuly, Г. Сугурбекова. ENHANCEMENT OF POWER CONVERSION EFFICIENCY OF DYE-SENSITIZED SOLAR CELLS VIA INCORPORATION OF GAN SEMICONDUCTOR MATERIAL SYNTHESIZED IN HOT-WALL CHEMICAL VAPOR DEPOSITION FURNACE. DOI: 10.31489/2024no4/131-139

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What are the advantages of using an Infrared Rapid Heating Furnace? Capture Transient Atomic Migrations in Steel

- What is the primary function of a high-temperature muffle furnace in graphene oxide synthesis? Maximize Carbon Yield

- How is a muffle furnace utilized in environmental analysis? Essential for Precise Organic and Inorganic Composition Testing

- How does a muffle furnace function in Co3O4 nanocatalyst calcination? Optimize Your Catalyst Performance

- How does muffle furnace temperature control affect copper(II) orthoperiodate synthesis? Master Phase Purity

- What are some common industrial applications of muffle furnaces? Unlock Precision Heat for Your Materials

- How do high-temperature furnaces facilitate ZnZrOx and InZrOx catalysts? Optimize Your Solid Solution Synthesis

- How does a box type electric furnace work? Master Precision Heating for Your Lab