At its core, a box type electric furnace operates by converting electrical energy into heat through specialized heating elements. This process, known as resistive heating, uniformly raises the temperature inside an insulated chamber, heating the materials within through a combination of thermal radiation and conduction.

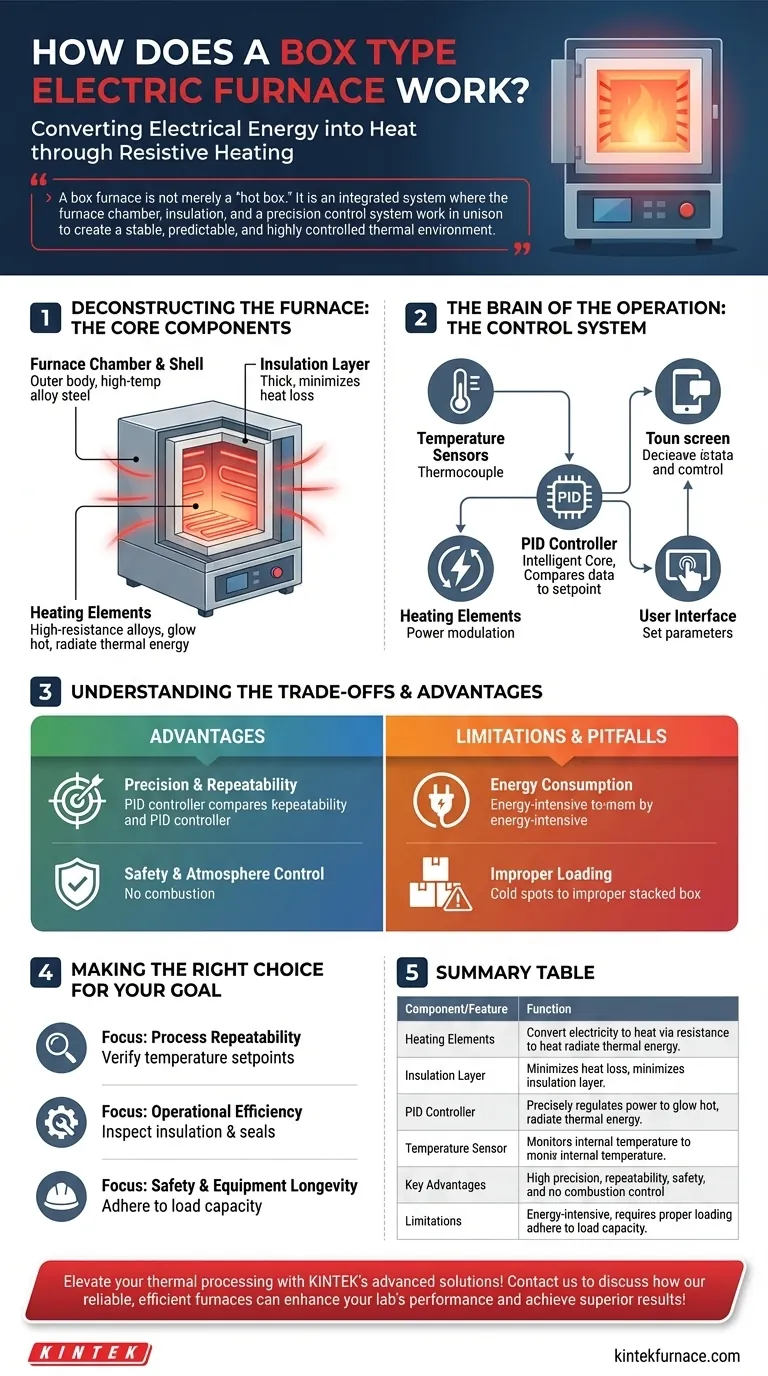

A box furnace is not merely a "hot box." It is an integrated system where the furnace chamber, insulation, and a precision control system work in unison to create a stable, predictable, and highly controlled thermal environment.

Deconstructing the Furnace: The Core Components

To truly understand its function, we must look at the key components that enable its performance. Each part plays a critical role in achieving the desired temperature and maintaining efficiency.

The Furnace Chamber and Shell

The outer body and inner chamber are typically constructed from high-temperature alloy steel or stainless steel. This provides the structural integrity needed to contain extreme heat and resist warping over many thermal cycles.

The Insulation Layer

Sandwiched between the outer shell and the inner chamber is a thick insulation layer. This is arguably the most critical component for efficiency, as it minimizes heat loss to the surrounding environment, ensuring the electrical energy consumed is used for heating the payload, not the room.

The Heating Elements

These are the heart of the furnace. Usually made of high-resistance alloys, these elements are strategically placed within the chamber. When a controlled electric current passes through them, their natural electrical resistance causes them to glow hot, radiating thermal energy throughout the chamber.

The Brain of the Operation: The Control System

A box furnace's value lies in its precision. This precision is not accidental; it is managed by a sophisticated electronic control system that acts as the furnace's brain.

Temperature Sensors

A temperature sensor, most commonly a thermocouple, is placed inside the furnace chamber. It acts as the system's eyes, constantly measuring the internal temperature and feeding that data back to the controller.

The PID Controller

The PID (Proportional-Integral-Derivative) controller is the intelligent core of the system. It receives data from the temperature sensor and compares it to the desired setpoint. It then calculates and modulates the exact amount of power to send to the heating elements to reach and maintain that temperature with minimal overshoot or fluctuation.

The User Interface

Modern furnaces use a touch screen or digital interface that allows the operator to set key parameters like target temperature, heating ramp rates, and soak times. This simplifies operation and allows for the automation of complex heating cycles.

Understanding the Trade-offs and Advantages

While highly effective, it's important to view the box furnace objectively to understand its strengths and operational realities.

Advantage: Precision and Repeatability

The combination of a PID controller and electric heating elements allows for extremely high temperature control accuracy. This makes the process highly repeatable, which is critical for scientific research and quality-controlled manufacturing.

Advantage: Safety and Atmosphere Control

Because there is no combustion, the furnace operates cleanly without introducing byproducts into the chamber. This makes it ideal for processes that require a specific, controlled atmosphere (e.g., inert gas or vacuum).

Limitation: Energy Consumption

Resistive heating is effective but can be energy-intensive, especially for large furnaces or very high temperatures. The operational cost is a direct function of electricity prices and the quality of the furnace's insulation.

Pitfall: Improper Loading

Overloading the furnace or placing items improperly can create cold spots and lead to non-uniform heating. It is crucial to follow the manufacturer's guidelines to ensure both process quality and the longevity of the furnace itself.

Making the Right Choice for Your Goal

Your operational focus should align with the furnace's key systems. Before each use, a quick check of cleanliness, power connections, and door seals is fundamental.

- If your primary focus is process repeatability: Your attention should be on verifying the temperature setpoints and understanding the PID controller's behavior.

- If your primary focus is operational efficiency: Meticulously inspect the insulation and door seals for any signs of degradation to minimize costly heat loss.

- If your primary focus is safety and equipment longevity: Adhere strictly to the recommended load capacity and heating/cooling rates to prevent thermal shock.

By understanding these core principles, the furnace is transformed from a simple tool into a predictable and powerful asset for your work.

Summary Table:

| Component/Feature | Function |

|---|---|

| Heating Elements | Convert electricity to heat via resistance, glowing hot to radiate energy |

| Insulation Layer | Minimizes heat loss, improving efficiency and temperature stability |

| PID Controller | Precisely regulates power to maintain set temperature with minimal fluctuation |

| Temperature Sensor | Monitors internal temperature and feeds data to the controller |

| Key Advantages | High precision, repeatability, safety with no combustion, atmosphere control |

| Limitations | Energy-intensive, requires proper loading to avoid cold spots |

Elevate your thermal processing with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our reliable, efficient furnaces can enhance your lab's performance and achieve superior results!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What happens to convective and radiative heat transfer effects at high furnace gas temperatures? Radiation Dominates for Superior Heating

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing