In environmental analysis, a muffle furnace is primarily used to determine the organic and inorganic composition of a sample through high-temperature combustion. This destructive process, known as ashing or gravimetric analysis, allows scientists to precisely measure the amount of volatile solids (organic matter) and fixed solids (inorganic ash) in materials like soil, sediment, water residue, and sludge. This data is fundamental for water quality assessment, soil health analysis, and pollution control studies.

The core function of a muffle furnace in environmental science is not just heating, but controlled decomposition. By using extreme, consistent heat to burn away all organic material, it isolates the inorganic residue, allowing for a precise quantitative analysis of a sample's fundamental makeup.

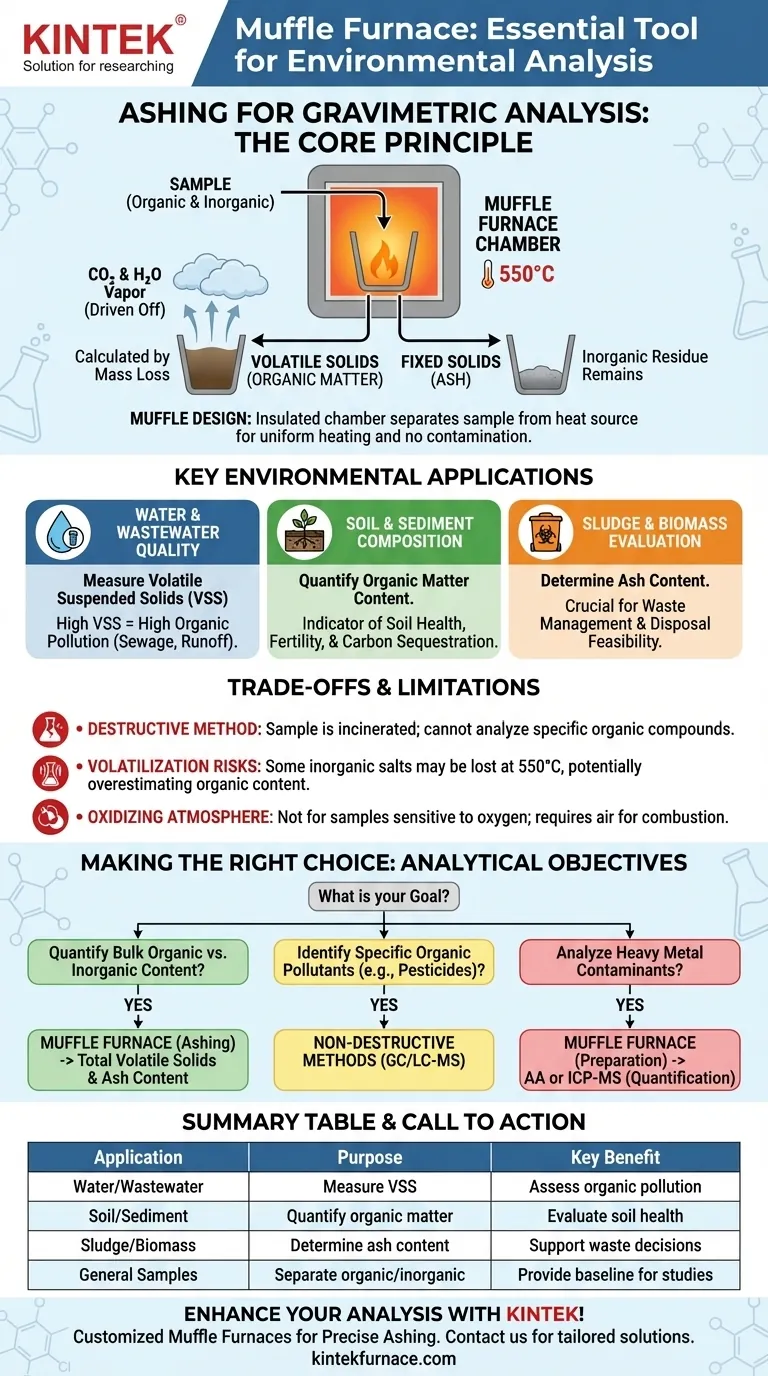

The Core Principle: Ashing for Gravimetric Analysis

A muffle furnace's utility is rooted in a simple but powerful analytical technique. It operates on the principle that organic and inorganic compounds behave differently at high temperatures.

What is Ashing?

Ashing is the process of heating a sample to a high temperature, typically 550°C, in the presence of oxygen. This extreme heat causes all organic matter to combust and turn into carbon dioxide and water vapor, which are then driven off.

The material that remains after this process is the ash—the inorganic, non-volatile component of the original sample.

Why This Measurement is Crucial

By weighing the sample before and after ashing, an analyst can calculate the mass lost. This loss in mass corresponds to the volatile solids, which is a reliable proxy for the total organic matter content.

The remaining mass is the fixed solids, or ash content. This simple gravimetric analysis provides a foundational understanding of the sample's composition.

The Role of the "Muffle"

The term "muffle" refers to the insulated inner chamber that separates the sample from the direct flame or heating elements. This design ensures that the sample is heated uniformly and is not contaminated by the byproducts of combustion from the heat source itself.

This contamination control is critical for achieving accurate and repeatable analytical results.

Key Environmental Applications

The data derived from ashing is applied across several critical areas of environmental monitoring and research.

Analyzing Water and Wastewater Quality

Muffle furnaces are essential for distinguishing between different types of solids in a water sample. The test for Volatile Suspended Solids (VSS) involves ashing the residue from a filtered water sample. A high VSS percentage often indicates a high level of organic pollution from sources like sewage or agricultural runoff.

Assessing Soil and Sediment Composition

The organic matter content of soil is a primary indicator of its health and fertility. By ashing soil samples, environmental scientists can precisely quantify this organic content, which is vital for understanding carbon sequestration, nutrient cycling, and the impact of land use or contamination.

Evaluating Sludge and Biomass

In waste management and pollution control, muffle furnaces are used to determine the ash content of materials like sewage sludge or industrial biomass. This data is essential for evaluating the effectiveness of wastewater treatment processes and for determining the feasibility of disposal methods like incineration or use as fertilizer.

Understanding the Trade-offs and Limitations

While powerful, the muffle furnace is a specific tool with inherent limitations that must be understood to interpret results correctly.

It Is a Destructive Method

The most significant limitation is that ashing is a completely destructive process. The original sample is incinerated, meaning you cannot perform further analysis on specific organic compounds that were present. It tells you how much organic matter there was, not what it was.

Some Inorganic Compounds Can Volatilize

While the 550°C standard is designed to burn off organics, certain inorganic compounds and metal salts can also become volatile and be lost at this temperature. This can lead to a slight overestimation of the organic content and an underestimation of the ash.

Not for Atmosphere-Sensitive Samples

A standard muffle furnace operates in an oxygen-rich air atmosphere to facilitate combustion. It is unsuitable for materials that might react with oxygen or require an inert atmosphere (like nitrogen or argon) for heat treatment.

Making the Right Choice for Your Goal

To apply this technique correctly, you must align the method with your analytical objective.

- If your primary focus is to quantify bulk organic vs. inorganic content: A muffle furnace is the industry-standard tool for determining total volatile solids and ash content in environmental samples.

- If your primary focus is to identify specific organic pollutants (like pesticides or hydrocarbons): You must use non-destructive techniques like gas or liquid chromatography (GC/LC-MS), as ashing would completely destroy these target molecules.

- If your primary focus is to analyze heavy metal contaminants: Use the furnace for initial sample preparation (ashing) to remove the organic interference, but the final quantification requires a separate method like Atomic Absorption (AA) or ICP-MS on the resulting ash.

Ultimately, the muffle furnace provides a foundational, quantitative baseline that is an essential step in a complete environmental assessment.

Summary Table:

| Application | Purpose | Key Benefit |

|---|---|---|

| Water/Wastewater Analysis | Measure Volatile Suspended Solids (VSS) | Assess organic pollution levels |

| Soil/Sediment Analysis | Quantify organic matter content | Evaluate soil health and fertility |

| Sludge/Biomass Evaluation | Determine ash content | Support waste management decisions |

| General Environmental Samples | Separate organic and inorganic components | Provide baseline for pollution control |

Enhance your environmental analysis with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, improving accuracy and efficiency in ashing and gravimetric analysis. Contact us today to discuss how our products can support your environmental monitoring and research goals!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination