In advanced materials research, a muffle furnace serves as a high-precision oven that creates an exceptionally clean and controlled thermal environment. It is the primary tool for executing processes like heat treatment, material synthesis, and thermal analysis. By isolating the material from heating elements and combustion byproducts, the furnace ensures that the results are due to the intended thermal profile alone, not from unwanted chemical contamination.

The core value of a muffle furnace is not just its ability to reach high temperatures. It is the power to create a pristine, reproducible thermal environment that allows researchers to precisely manipulate a material's fundamental atomic structure and chemical properties.

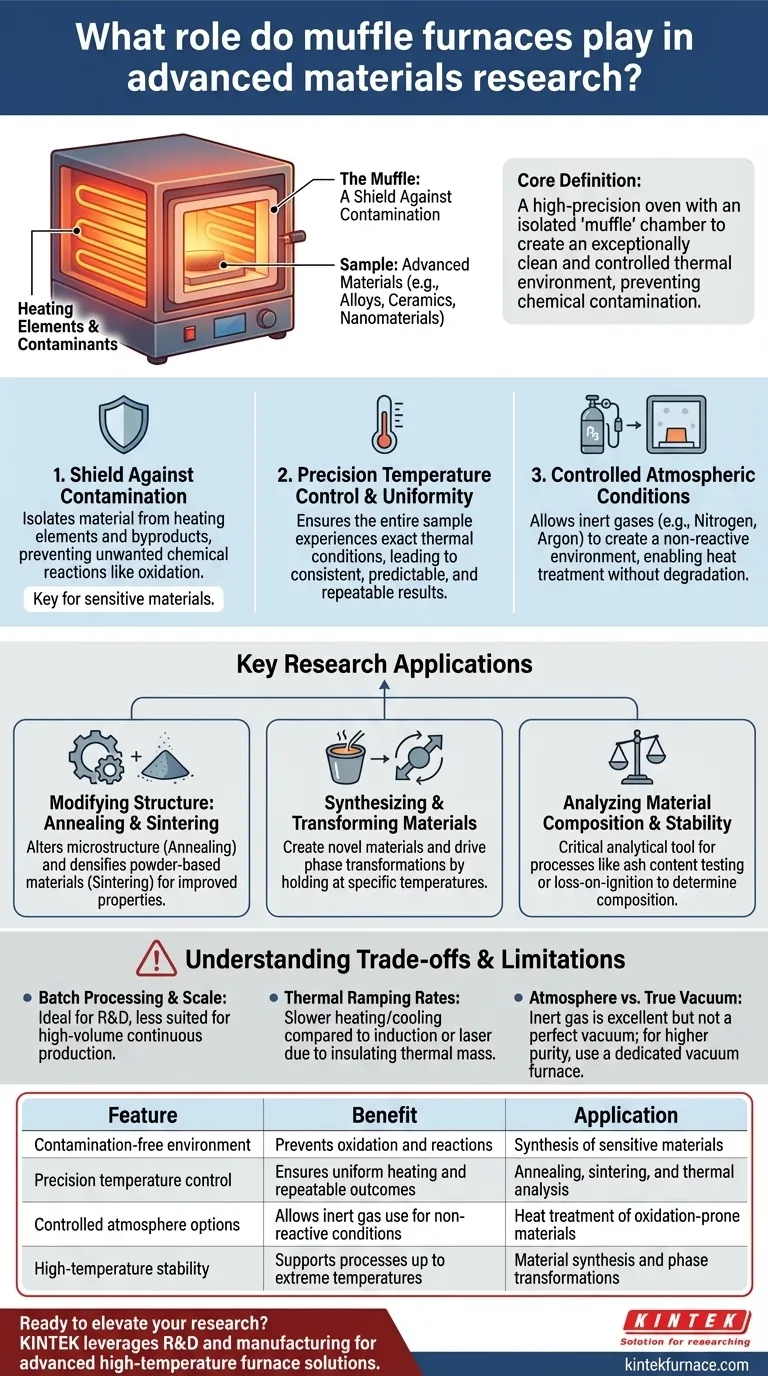

The Foundation: Why a "Muffle" is Critical

A standard furnace heats materials, but a muffle furnace refines the process. Its unique design is engineered to solve common problems in high-temperature research, making it indispensable for developing sensitive, high-performance materials.

The "Muffle": A Shield Against Contamination

The defining feature is the muffle—a separate inner chamber that contains the material being heated. This chamber acts as a physical barrier, separating the sample from the heating elements and any potential contaminants they might release.

This isolation is crucial for preventing unwanted chemical reactions, such as oxidation, that can compromise the integrity of advanced alloys, ceramics, and nanomaterials.

Precision Temperature Control and Uniformity

Advanced materials derive their properties from their specific microstructures, which are highly sensitive to temperature fluctuations. Muffle furnaces provide exceptional temperature uniformity throughout the chamber.

This ensures that the entire sample experiences the exact same thermal conditions, leading to consistent, predictable, and repeatable results—a non-negotiable requirement for scientific research and quality control.

Controlled Atmospheric Conditions

Many advanced materials, particularly metals and certain nanomaterials, will readily oxidize when heated in air. More advanced muffle furnaces allow for the introduction of inert gases, such as nitrogen or argon.

By purging the oxygen, these furnaces create a controlled, non-reactive atmosphere, enabling the heat treatment of sensitive materials without degradation.

Key Research Applications

The controlled environment of a muffle furnace is leveraged for several distinct purposes in materials science, from modifying existing materials to creating entirely new ones.

Modifying Structure: Annealing and Sintering

Annealing is a heat treatment process that alters a material's microstructure to relieve internal stresses, increase ductility, and improve grain structure. The furnace's slow, controlled cooling is key to achieving these properties.

Sintering is used to densify and bond powder-based materials, such as ceramics or metal powders, by heating them below their melting point. The uniform heat of the furnace ensures consistent densification and strength throughout the final part.

Synthesizing and Transforming Materials

Muffle furnaces are used to synthesize novel materials and drive phase transformations. By holding a material at a specific temperature for a set duration, researchers can change its crystalline structure to unlock different properties.

This is fundamental in the development of technical ceramics, glass, and certain alloys where the material's phase dictates its performance.

Analyzing Material Composition and Stability

The furnace is also a critical analytical tool. Processes like ash content testing or loss-on-ignition involve heating a sample to burn off organic components, leaving only the inorganic ash.

The furnace's precision ensures that the weight difference before and after heating is an accurate measure of the material's composition, providing vital data for quality control and material characterization.

Understanding the Trade-offs and Limitations

While powerful, muffle furnaces are not the universal solution for all thermal processing needs. Understanding their limitations is key to using them effectively.

Batch Processing and Scale

Most laboratory muffle furnaces are designed for smaller, batch-based processing. They are ideal for research, development, and quality control but are generally not suited for high-volume, continuous industrial production.

Thermal Ramping Rates

While highly stable, the thermal mass of the insulating materials means that muffle furnaces may have slower heating and cooling rates compared to other technologies like induction or laser heating. They are not ideal for experiments requiring rapid thermal cycling.

Atmosphere vs. True Vacuum

An inert gas atmosphere is excellent for preventing oxidation, but it is not a perfect vacuum. For materials that require an even higher level of purity or are sensitive to any atmospheric molecules, a dedicated vacuum furnace is the more appropriate tool.

Making the Right Choice for Your Goal

Selecting and using a muffle furnace correctly depends entirely on your experimental objective.

- If your primary focus is altering mechanical properties: Prioritize a furnace with a programmable controller that allows you to design precise heating, soaking, and cooling profiles for annealing or sintering.

- If your primary focus is synthesizing new compounds: Choose a furnace with robust atmosphere control to prevent oxidation and other unwanted chemical reactions during synthesis.

- If your primary focus is analytical testing: Select a furnace renowned for its exceptional temperature uniformity and stability to ensure your measurements are accurate and repeatable.

Ultimately, mastering the muffle furnace is fundamental to translating theoretical material concepts into tangible, high-performance realities.

Summary Table:

| Feature | Benefit | Application |

|---|---|---|

| Contamination-free environment | Prevents oxidation and unwanted reactions | Synthesis of sensitive materials like alloys and ceramics |

| Precision temperature control | Ensures uniform heating and repeatable outcomes | Annealing, sintering, and thermal analysis |

| Controlled atmosphere options | Allows inert gas use for non-reactive conditions | Heat treatment of oxidation-prone materials |

| High-temperature stability | Supports processes up to extreme temperatures | Material synthesis and phase transformations |

Ready to elevate your advanced materials research with precision thermal solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Whether you need contamination-free environments, precise temperature control, or tailored systems, we deliver reliable performance to accelerate your innovations. Contact us today to discuss how we can support your research goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment