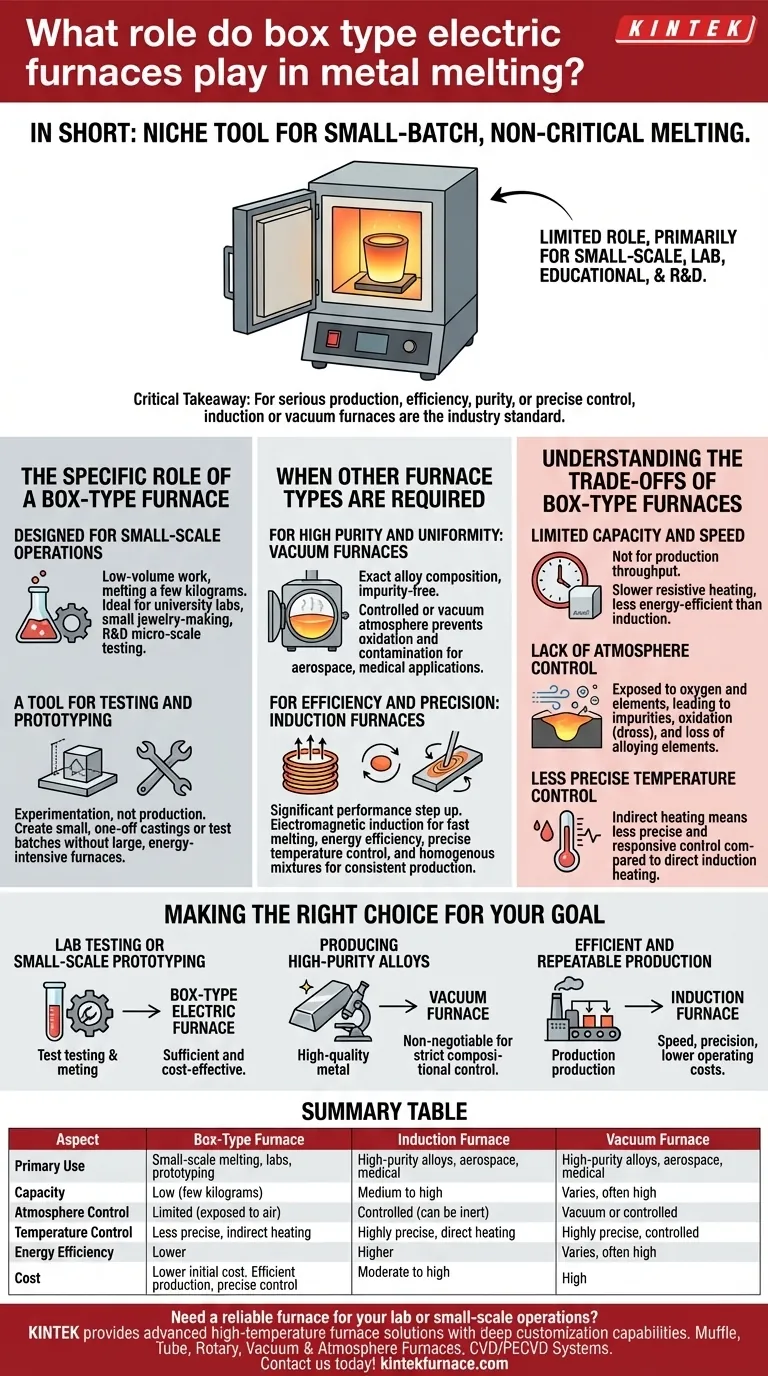

In short, a box-type electric furnace plays a very specific and limited role in metal melting. While most commonly associated with heat treatment, certain models are designed for melting small quantities of non-ferrous metals or alloys, primarily in laboratory, educational, or small-scale prototyping environments.

The critical takeaway is that a box-type furnace is a niche tool for small-batch, non-critical melting. For any serious production requiring efficiency, purity, or precise control, specialized technologies like induction or vacuum furnaces are the industry standard.

The Specific Role of a Box-Type Furnace

A box-type furnace is defined by its form factor—a simple, insulated chamber with a door. When used for melting, it typically relies on electric resistance heating elements to bring a crucible of metal up to temperature.

Designed for Small-Scale Operations

These furnaces are fundamentally designed for low-volume work. Their simple construction makes them a cost-effective choice for melting a few kilograms of metal at a time.

This makes them suitable for university labs, small jewelry-making operations, or R&D departments testing new alloy compositions on a micro-scale.

A Tool for Testing and Prototyping

The primary application is not production, but experimentation. A box-type furnace allows a metallurgist or technician to create small, one-off castings or test batches without firing up a large, energy-intensive production furnace.

When Other Furnace Types Are Required

The limitations of a box-type furnace become clear when compared to more advanced melting technologies. The choice of furnace is dictated entirely by the requirements for purity, efficiency, and scale.

For High Purity and Uniformity: Vacuum Furnaces

When the final alloy composition must be exact and free from impurities, a vacuum furnace is necessary. By melting the metal in a controlled or vacuum atmosphere, it prevents oxidation and contamination from ambient air.

This level of control is crucial for aerospace, medical, and other high-performance applications where material integrity is paramount.

For Efficiency and Precision: Induction Furnaces

Induction furnaces represent a significant step up in performance. They use electromagnetic induction to heat the metal directly, resulting in much faster melting times and greater energy efficiency.

This technology offers precise temperature control and promotes a stirring action within the molten metal, leading to a more homogenous mixture. They are a clean, cost-effective choice for consistent production work.

Understanding the Trade-offs of Box-Type Furnaces

Choosing a box-type furnace for melting involves accepting a clear set of compromises in exchange for simplicity and lower initial cost.

Limited Capacity and Speed

The most obvious trade-off is volume. These furnaces are not built for production throughput. The resistive heating method is also significantly slower and less energy-efficient than induction heating.

Lack of Atmosphere Control

A standard box furnace offers no protection from the atmosphere. This means metals are exposed to oxygen and other elements during melting, which can lead to impurities, oxidation (dross), and a loss of valuable alloying elements.

Less Precise Temperature Control

While modern controllers have improved, the indirect heating method of a box furnace generally offers less precise and responsive temperature control compared to an induction system, where heat is generated directly within the metal itself.

Making the Right Choice for Your Goal

Selecting the correct furnace is a matter of aligning the technology's capabilities with your specific operational needs.

- If your primary focus is lab testing or small-scale prototyping: A box-type electric furnace can be a sufficient and cost-effective tool.

- If your primary focus is producing high-purity alloys: A vacuum furnace is non-negotiable to ensure strict compositional control.

- If your primary focus is efficient and repeatable production: An induction furnace provides the necessary speed, precision, and lower operating costs.

Ultimately, understanding the strengths and limitations of each furnace type empowers you to select the right tool for the job.

Summary Table:

| Aspect | Box-Type Furnace | Induction Furnace | Vacuum Furnace |

|---|---|---|---|

| Primary Use | Small-scale melting, labs, prototyping | Efficient production, precise control | High-purity alloys, aerospace, medical |

| Capacity | Low (few kilograms) | Medium to high | Varies, often high |

| Atmosphere Control | Limited (exposed to air) | Controlled (can be inert) | Vacuum or controlled |

| Temperature Control | Less precise, indirect heating | Highly precise, direct heating | Highly precise, controlled |

| Energy Efficiency | Lower | Higher | Varies, often high |

| Cost | Lower initial cost | Moderate to high | High |

Need a reliable furnace for your lab or small-scale operations? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your efficiency and results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability