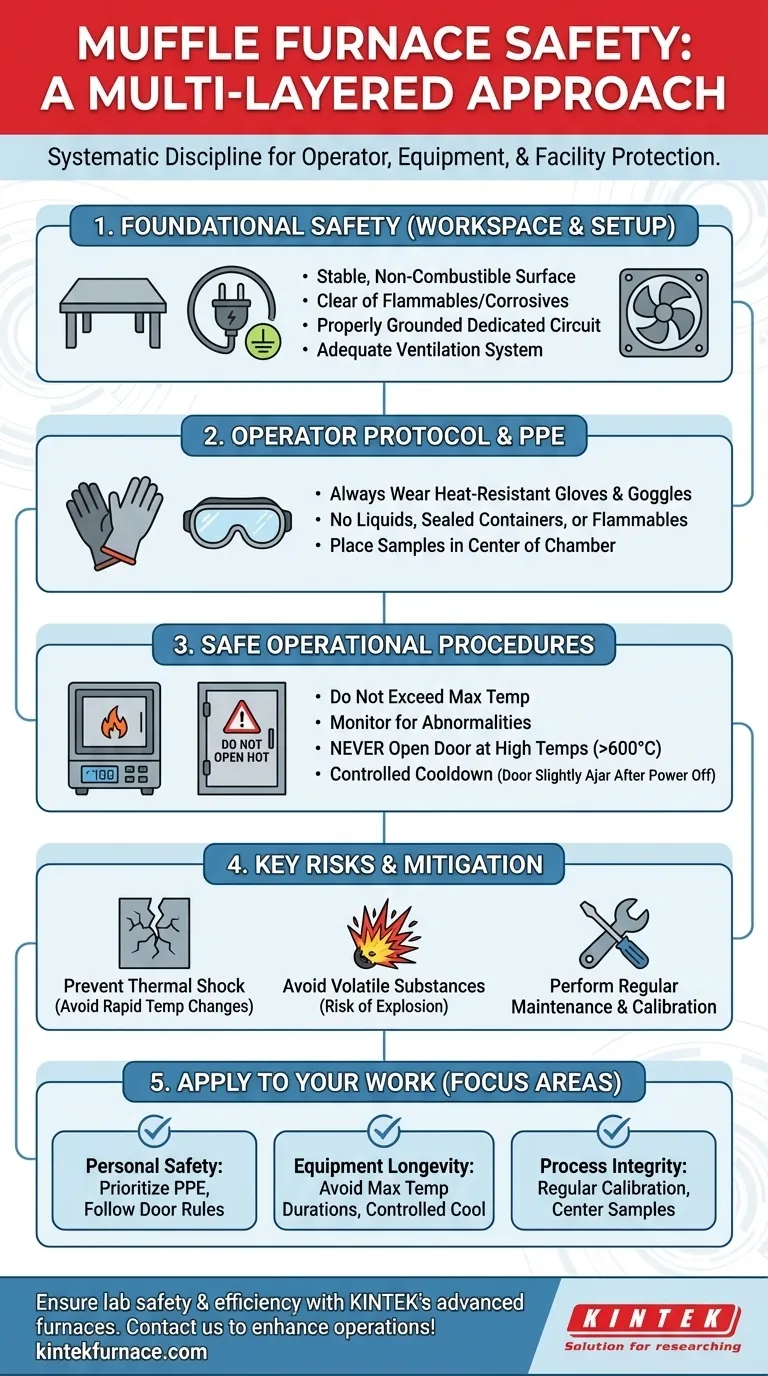

To safely operate a muffle furnace, you must implement a multi-layered approach that addresses electrical safety, environmental hazards, and operational protocols. This involves properly grounding the unit in a cleared workspace, always wearing heat-resistant personal protective equipment (PPE), never placing prohibited materials like liquids or flammables inside, and adhering to strict procedures for heating, opening the door, and cooling.

A muffle furnace's immense heating power demands unwavering respect. True safety is not a single checklist item but a systematic discipline that protects the operator, the equipment, and the facility before, during, and after every single use.

Foundational Safety: The Workspace and Electrical Setup

The most critical safety measures begin before you ever turn the furnace on. An improper setup creates inherent risks that cannot be mitigated by operator skill alone.

Ensuring a Stable and Secure Location

Your furnace must be placed on a completely stable, level, and non-combustible surface, such as a dedicated cement platform.

The immediate area must be kept clear of all flammable, explosive, or corrosive substances. A muffle furnace radiates significant heat, creating a fire hazard if combustible materials are stored nearby.

Establishing Proper Electrical Integrity

The furnace must be properly grounded to prevent the risk of severe electric shock. This is non-negotiable.

Use a dedicated electrical circuit with appropriate plugs, sockets, and fuses rated for the furnace's power draw. This prevents overloading and potential electrical fires.

Verifying Adequate Ventilation

Ensure the room has proper ventilation. Some samples may release fumes or gases when heated, and a robust ventilation system is necessary to safely exhaust them from the laboratory.

Operator Protocol and Personal Protection

With the environment secured, the focus shifts to the operator's actions and personal safety gear.

Using Personal Protective Equipment (PPE)

Always wear heat-resistant gloves when handling samples, tools, or any part of the furnace, even if you believe it has cooled. Surfaces can retain dangerous levels of heat long after the power is off.

Safety goggles are essential to protect your eyes from heat radiation and any potential debris.

Handling Samples Correctly

Never place liquids, oily substances, or sealed containers in the furnace. Rapid heating can cause them to vaporize, boil over, or explode, creating a pressure hazard and damaging the furnace interior.

Do not attempt to process flammable or explosive materials. This is extremely dangerous and can lead to catastrophic failure.

Place samples neatly in the center of the furnace chamber to ensure even heating and stability.

Safe Operational Procedures

Adhering to a strict operational sequence is crucial for preventing accidents and preserving the life of the furnace.

Managing the Heating Cycle

Do not exceed the maximum rated temperature of the furnace. Furthermore, avoid operating at the upper-end of the rated temperature for unnecessarily extended periods, as this shortens the lifespan of the heating elements.

Always monitor the temperature display. If you notice erratic behavior or any other abnormality, cut the power immediately and investigate once the unit is safe.

The Critical Rule of the Furnace Door

Close the furnace door gently to avoid jarring the samples or damaging the door seals.

Most importantly, do not open the furnace door at high temperatures (e.g., above 600°C). The sudden inrush of cool air can cause thermal shock, cracking the ceramic refractory material and ruining the furnace.

When loading or unloading, cut power to the heating elements and minimize the time the door is open to retain heat and reduce thermal stress.

Executing a Safe Shutdown

After the cycle is complete, turn off the power. Remove your samples using the proper tools and PPE.

To facilitate a controlled cooldown and protect the refractory materials, leave the furnace door slightly ajar as it cools. Once completely cool and not in use, close the door to keep the chamber clean.

Understanding the Key Risks

Avoiding mistakes is as important as following correct procedures. Awareness of these specific dangers is the foundation of an expert operator's mindset.

The Danger of Thermal Shock

The ceramic insulation, or refractory, inside a muffle furnace is brittle. A rapid temperature change—like opening a very hot door—creates immense internal stress, leading to cracks and failure. This is why a controlled cooldown is mandatory.

The Consequence of Prohibited Materials

Introducing volatile substances is the single greatest risk for a catastrophic event. Liquids can superheat and flash to steam, while flammables can ignite. The furnace is designed only for stable, solid materials.

The Cost of Neglected Maintenance

An uncalibrated furnace gives false temperature readings, potentially ruining samples or running the furnace hotter than intended. Heating elements degrade over time and must be inspected and replaced as part of a regular maintenance schedule to ensure consistent, safe performance.

Applying This to Your Work

Use this guidance to create an ironclad standard operating procedure for your laboratory.

- If your primary focus is personal safety: Always prioritize PPE and never, under any circumstance, open a hot furnace door above the manufacturer's recommended temperature.

- If your primary focus is equipment longevity: Avoid running at maximum temperature for long durations, ensure a controlled cooldown, and perform regular maintenance checks.

- If your primary focus is process integrity: Calibrate your furnace regularly and place samples in the center of the chamber to guarantee accurate and repeatable results.

Ultimately, consistent adherence to a rigorous safety protocol is the only way to operate this powerful tool effectively and without incident.

Summary Table:

| Safety Aspect | Key Measures |

|---|---|

| Workspace Setup | Stable surface, clear of flammables, proper grounding, adequate ventilation |

| Operator Protocol | Wear heat-resistant gloves and goggles, handle samples correctly, avoid prohibited materials |

| Operational Procedures | Monitor temperature, avoid opening door at high temps, execute controlled shutdown |

| Risk Awareness | Prevent thermal shock, avoid volatile substances, perform regular maintenance |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnaces. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs. Contact us today to discuss how our products can enhance your operations!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the key role of a muffle furnace in the pretreatment of boron sludge and szaibelyite? Unlock Higher Process Efficiency

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis