At its core, a muffle furnace is a high-temperature oven used for a wide range of material transformations and analyses. Its primary applications fall into three main categories: material analysis (like ashing), material modification (such as the heat treatment of metals), and material synthesis (including the creation of ceramics and glass). These processes all rely on the furnace's ability to provide precise, high heat in a controlled environment.

The true value of a muffle furnace lies in its ability to deliver precise, uniform heat while isolating the sample from the heating elements. This design prevents contamination from combustion byproducts or the elements themselves, making it the ideal tool for processes that require thermal transformation without chemical interference.

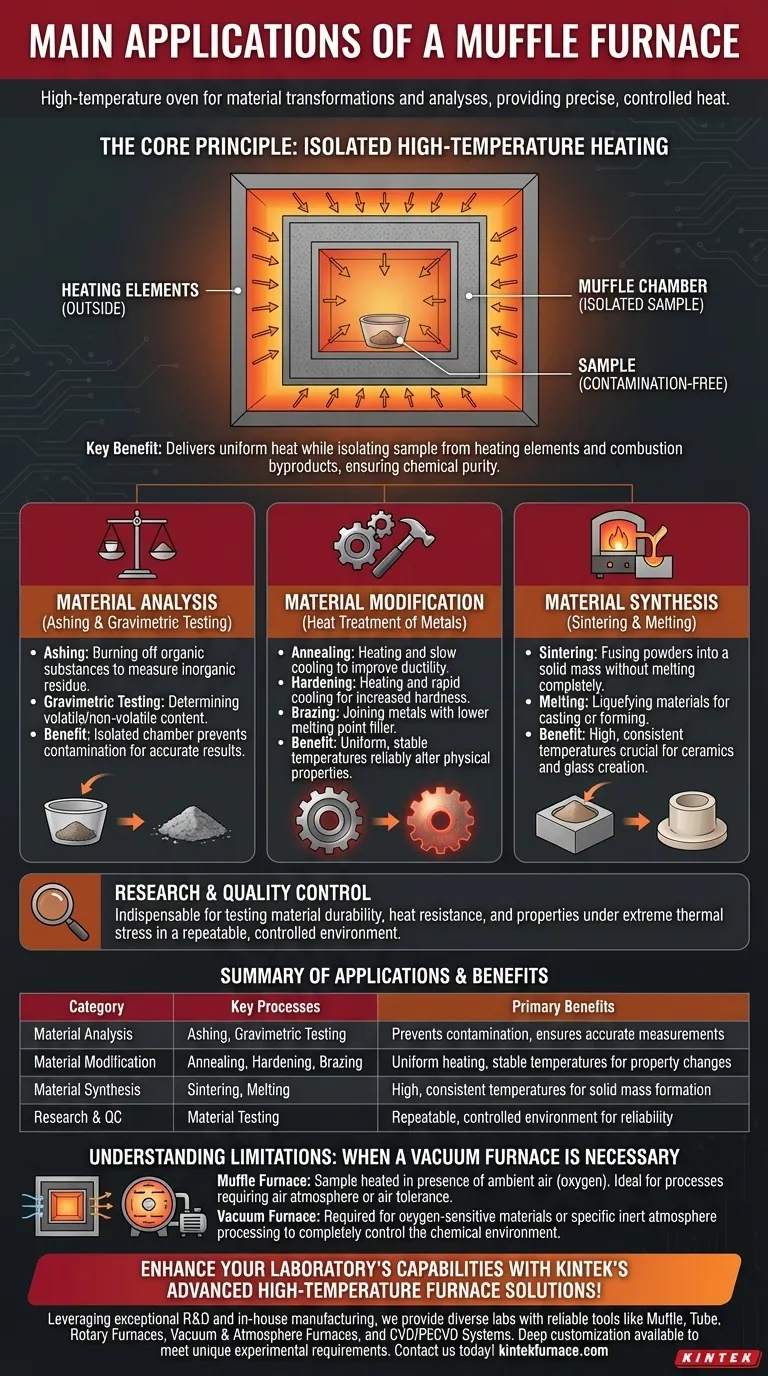

The Core Principle: Isolated High-Temperature Heating

To understand the furnace's applications, you must first understand its design. The key feature is not just the heat, but the isolation.

What is a "Muffle"?

The term "muffle" refers to the furnace's inner chamber, which is typically made of a high-temperature ceramic. This chamber encloses the sample being heated.

The heating elements are positioned on the outside of this muffle, heating it indirectly. This creates a box-within-a-box structure that separates the material from any direct contact with the source of heat.

Why Isolation Matters

This separation is critical. It ensures that any byproducts from the heating elements (like gases or flaking particles) do not contaminate the sample.

This makes the muffle furnace essential for applications where the chemical and physical purity of the final result is paramount, such as in analytical chemistry or quality control.

Key Functional Applications Breakdown

The unique design of the muffle furnace makes it the preferred tool for several specific, high-temperature industrial and laboratory processes.

Material Analysis: Ashing and Gravimetric Testing

Ashing is the process of burning away all organic substances in a sample to measure the weight of the inorganic residue (ash). This is a common quality control test in food, pharmaceutical, and environmental science.

The muffle furnace excels here because its isolated chamber ensures that the only material left behind is from the sample itself, providing an accurate, uncontaminated measurement. It's also used for determining volatile and non-volatile content in materials.

Material Modification: Heat Treatment of Metals

Processes like annealing, hardening, and brazing require heating metals to specific temperatures to change their physical properties, such as hardness or ductility.

A muffle furnace provides the extremely uniform and stable temperatures needed to reliably alter a metal's crystalline structure. The isolation prevents surface contamination that could occur in a direct-fired furnace.

Material Synthesis: Sintering and Melting

Sintering is the process of fusing powders into a solid mass using heat, without melting it completely. This is fundamental to creating ceramics, glass, and some metal components.

The furnace's ability to maintain high, consistent temperatures for extended periods is crucial for successful sintering and melting, ensuring a uniform final product.

Research and Quality Control

In a broader sense, muffle furnaces are indispensable for material testing. Researchers and quality control technicians use them to test a material's durability, heat resistance, and other properties under extreme thermal stress.

The furnace provides a repeatable, controlled high-temperature environment, which is the foundation of reliable scientific testing and product verification.

Understanding the Trade-offs and Limitations

While powerful, a muffle furnace is not the solution for every high-temperature need. Understanding its limitations is key to using it correctly.

Contamination Control vs. Atmospheric Control

A standard muffle furnace prevents contamination from the heating elements, but it does not control the atmosphere within the chamber. The sample is typically heated in the presence of ambient air (and thus, oxygen).

For many applications like ashing, the presence of oxygen is necessary for combustion. For others, like basic metal annealing, it is acceptable.

When a Vacuum Furnace Is Necessary

If a process is highly sensitive to oxygen or requires a specific inert atmosphere (like argon or nitrogen), a muffle furnace is the wrong tool.

Applications such as the heat treatment of reactive metals (like titanium) or advanced ceramic processing require a vacuum furnace or an inert gas furnace. These tools allow for complete control over the chemical environment during heating.

Making the Right Choice for Your Goal

Your specific objective determines whether a muffle furnace is the appropriate instrument.

- If your primary focus is analytical purity: A muffle furnace is ideal for ashing, gravimetric analysis, and determining inorganic content where preventing contamination is paramount.

- If your primary focus is modifying metal properties: Use a muffle furnace for standard heat treatments like annealing and hardening that require consistent heat in an air atmosphere.

- If your primary focus is creating ceramic or glass objects: The furnace's high, stable temperatures are perfectly suited for sintering, melting, and forming these materials.

- If your process is sensitive to oxygen: A muffle furnace is not the correct tool; you must instead use a vacuum or inert atmosphere furnace.

Ultimately, selecting a muffle furnace is a decision for high-heat applications where thermal precision and sample purity in an air atmosphere are the defining requirements.

Summary Table:

| Application Category | Key Processes | Primary Benefits |

|---|---|---|

| Material Analysis | Ashing, Gravimetric Testing | Prevents contamination, ensures accurate measurements |

| Material Modification | Annealing, Hardening, Brazing | Uniform heating, stable temperatures for property changes |

| Material Synthesis | Sintering, Melting | High, consistent temperatures for solid mass formation |

| Research & Quality Control | Material Testing | Repeatable, controlled environment for reliability |

Enhance your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable tools like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior performance and efficiency. Contact us today to discuss how we can support your material transformation and analysis needs!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?