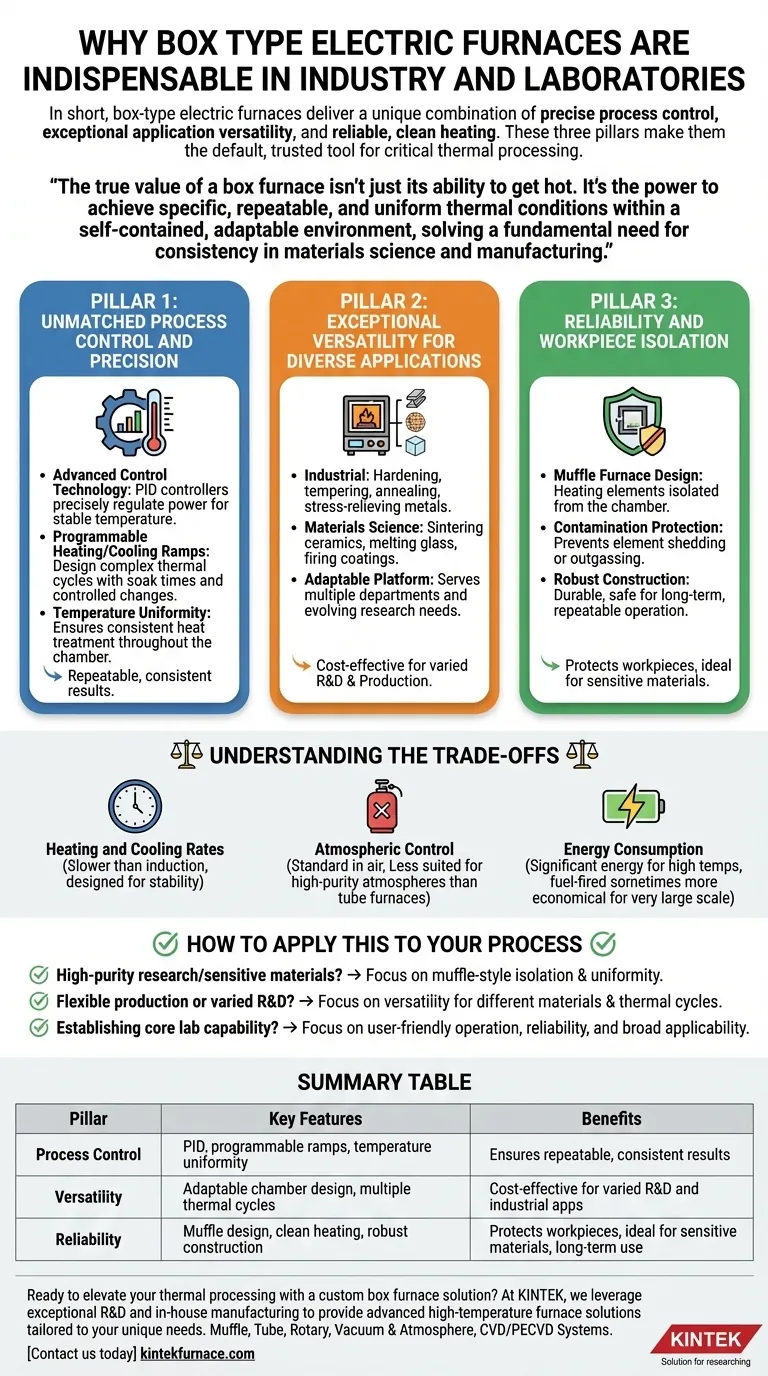

In short, box-type electric furnaces are indispensable because they deliver a unique combination of precise process control, exceptional application versatility, and reliable, clean heating. These three pillars make them the default, trusted tool for critical thermal processing in both demanding research and industrial production environments.

The true value of a box furnace isn't just its ability to get hot. It's the power to achieve specific, repeatable, and uniform thermal conditions within a self-contained, adaptable environment, solving a fundamental need for consistency in materials science and manufacturing.

The Pillars of Indispensability

A box furnace's value comes from a synthesis of key characteristics. Understanding these pillars explains why it has become a foundational piece of equipment in any facility performing heat treatment.

Pillar 1: Unmatched Process Control and Precision

The primary requirement for any serious thermal process is control. Results must be repeatable, and box furnaces are engineered to deliver this.

This is achieved through advanced control technology, typically using PID (Proportional-Integral-Derivative) controllers that precisely regulate power to maintain a set temperature with minimal deviation.

Furthermore, they offer programmable heating and cooling ramps. Users can design complex thermal cycles with specific soak times and controlled temperature changes, which is critical for processes like annealing metals or sintering advanced ceramics.

Finally, a well-designed furnace provides excellent temperature uniformity throughout the chamber, ensuring that an entire batch or a large component receives the same heat treatment.

Pillar 2: Exceptional Versatility for Diverse Applications

The simple, accessible chamber design makes the box furnace a highly adaptable tool. It is not a single-purpose device but a platform for a vast range of thermal processes.

In industrial settings, they are used for hardening, tempering, annealing, and stress-relieving metals. In materials science, they are essential for sintering ceramics, melting glass, and firing coatings.

This versatility means a single furnace can serve multiple departments or support evolving research needs, making it a highly cost-effective investment for laboratories and job shops.

Pillar 3: Reliability and Workpiece Isolation

When processing high-value materials, protecting the workpiece from contamination is non-negotiable. Many box furnaces are also muffle furnaces, meaning the heating elements are physically isolated from the main chamber.

This design prevents element shedding or outgassing from contaminating the material being processed, which is crucial for applications in electronics, medical devices, and chemical analysis.

Combined with their robust construction, this focus on a clean heating environment makes box furnaces a reliable, durable, and safe option for long-term, repeatable operation.

Understanding the Trade-offs

While indispensable, the box furnace is not the perfect solution for every conceivable heating task. Objectivity requires acknowledging its limitations.

Heating and Cooling Rates

Due to their thermal mass and insulation, box furnaces generally have slower heating and cooling rates compared to methods like induction heating. They are designed for stability and uniformity, not rapid thermal cycling.

Atmospheric Control

A standard box furnace operates in air. While some models can be sealed and purged with an inert gas like nitrogen or argon, they are not as inherently suited for high-purity controlled atmospheres as a dedicated tube furnace.

Energy Consumption

Bringing a well-insulated chamber to a high temperature and holding it there requires significant energy. For very large-scale industrial processes, fuel-fired furnaces can sometimes be more economical, though they sacrifice the precision and cleanliness of an electric model.

How to Apply This to Your Process

Choosing heating equipment depends entirely on your primary objective. Use these principles to guide your decision-making.

- If your primary focus is high-purity research or processing sensitive materials: The process isolation and precise temperature uniformity of a muffle-style box furnace are its most critical features.

- If your primary focus is flexible production or varied R&D: The box furnace's versatility to handle different materials, component sizes, and thermal cycles makes it an invaluable asset.

- If your primary focus is establishing a core laboratory capability: The balance of user-friendly operation, process reliability, and broad applicability makes the box furnace a foundational investment.

Ultimately, the box furnace's enduring role comes from its ability to provide a controlled, reliable, and versatile thermal processing environment for the widest possible range of applications.

Summary Table:

| Pillar | Key Features | Benefits |

|---|---|---|

| Process Control | PID controllers, programmable ramps, temperature uniformity | Ensures repeatable, consistent results for critical thermal processes |

| Versatility | Adaptable chamber design, supports multiple thermal cycles | Cost-effective for varied R&D and industrial applications like annealing and sintering |

| Reliability | Muffle design, clean heating, robust construction | Protects workpieces from contamination, ideal for sensitive materials and long-term use |

Ready to elevate your thermal processing with a custom box furnace solution? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're in materials science, industrial production, or research, we can help you achieve precise, reliable results. Contact us today to discuss how we can support your specific requirements and drive your success!

Visual Guide

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What role does a box muffle furnace play during the pre-carbonization stage of sugarcane bagasse? Expert Insights

- What role does a laboratory muffle furnace play in high-purity alpha-alumina prep? Master Calcination and Phase Shifts

- What functions does a high-temperature muffle furnace perform during cathode precursor processing?

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals